16

GB

• Water quality:

- In order for the heat pump to operate under good conditions and provide optimum performance, it is essential to

ensure that the system’s water circuit is clean. If the water circuit becomes clogged, this will significantly affect the

machine’s performance. The circuit must therefore be cleaned with suitable products in compliance with current

standards as soon as it is installed, both for new and renovation work.

We recommend the use of products which are compatible with all metals and synthetic materials and approved by

official bodies.

Recommendations regarding water quality:

- PH: 7 to 9,

- TH: 10 to 20°F,

- Dry material in suspension: < 2 g/l,

- Granulometry: < 0.4 mm,

- Chloride: 50 mg/l maximum,

- Conductivity: 150 to 350 µS/cm

2

,

- Fibre: no fibres.

Any disorder which may occur on our machines due to the poor quality of the fluid in the installation will not be

covered by the warranty.

6.1.3 - ELECTRICAL SYSTEM

• The power cables are well fixed to their connection terminals. Terminals that are poorly tightened may cause overheating

and malfunctions.

• The electric cables are well insulated from any sections of sheet metal or metal parts which could damage them.

• The probe, control and power cables are properly separated.

• The machine is earthed.

6.1.4 - MISCELLANEOUS

• Overall good condition of the apparatus.

• No tools or other foreign objects inside the apparatus.

6.2 - CONFIGURATION AND PARAMETERISATION

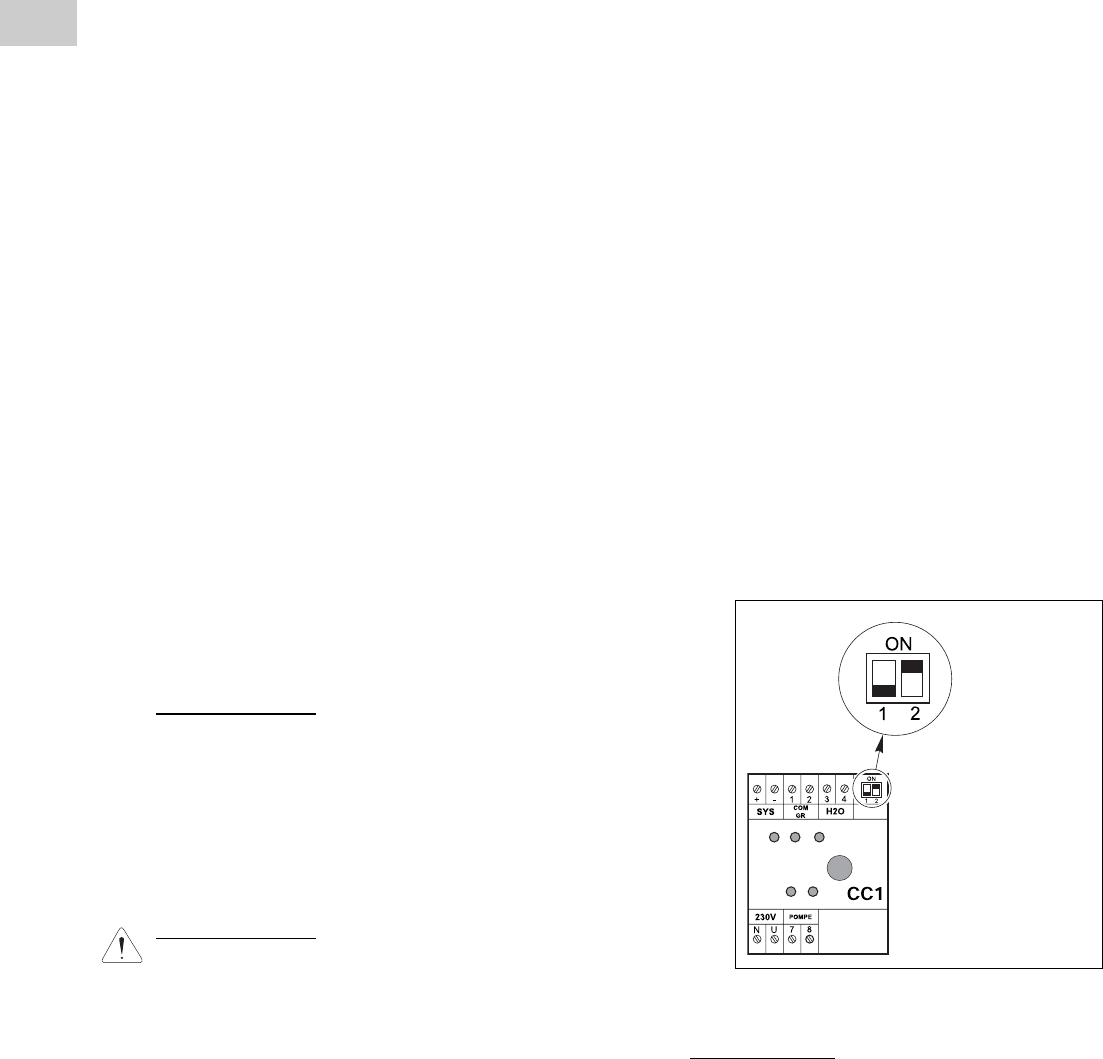

6.2.1 - MODULE CC1 CONFIGURATION

• The communication and control module manage the circulator and

the communication interface between the system and the generator.

It is equipped with 2 micro-switches, No. 1 and No. 2.

Micro-switch No. 1

:

In “ON” position, the circulator starts automatically if the outdoor

temperature is below 0°C to prevent the hydraulic circuit from

freezing. This position is recommended if the outdoor module is

installed in a location exposed to freezing temperatures (not

recommended).

The factory default setting for this micro-switch is “OFF”.

To use this function, set the unit in configuration

“Terminal unit or mixed zone” (see table of paragraph

“ZONE CONFIGURATION”).

Micro-switch No. 2

:

Must be set to “ON” (activates the water flow safety on the

system).

6.2.2 - SYSTEM PARAMETERISATION

• Make sure that the control unit selector is “OFF”.

• Check the parameterisation and adapt it accordingly based on the type of installation (see Technical Manual).

The parameters are set on the control box (refer to the Technical Manual, section PARAMETERS).

Micro-switches

No. 1 and No. 2

IMPORTANT