● The steel plate tank is designed to resist a

pressure that is higher than the working

pressure.

Its corrosion protection is provided by a

layer of vitrified enamel and an impressed

current anode.

● The heating element consists of a ceramic

element that heats the water inside the

tank.

- The ceramic element protected by an ena-

mel-coated sheath, which makes it unne-

cessary to empty the heater when replacing

the element.

● The thermostat controls the water tempe-

rature.

It is preset in the factory to the "upper stop

gauge", about 65°C +/- 5.

● A temperature circuit breaker is provided

for safety if the water temperature should

rise abnormally.

● The tank is protected against corrosion by

a very low voltage impressed electrical cur-

rent.

- The electronic panel permanently provi-

des the necessary current for this protec-

tion, both in peak hours and in off-peak

hours.

9

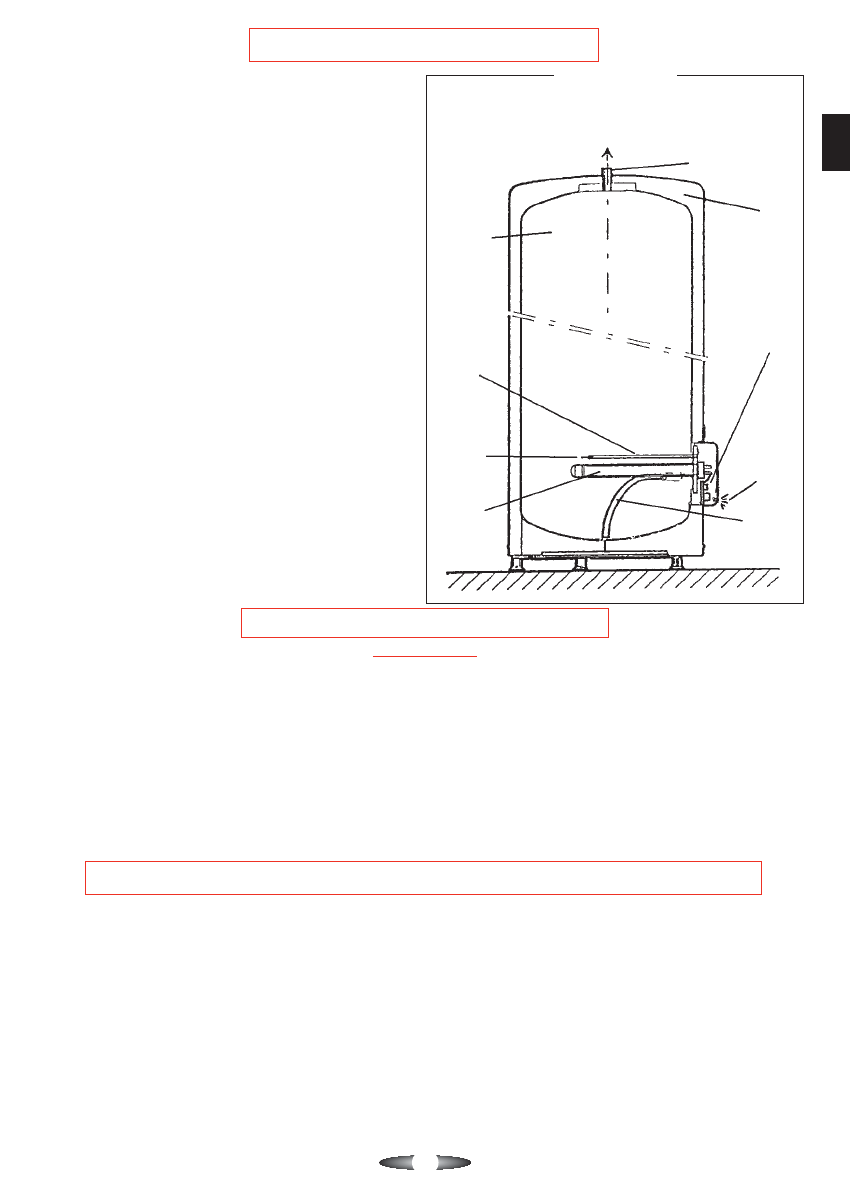

Water heater description

Vertical, floor-standing water heater with a

ceramic element and an "impressed current anode”

Internal enamel

coated protection

Hot water outlet

Cold water inlet

Thermal insulation

(injected polyurethane

foam)

Electronic thermostat

D.C. generator

(rectifier)

Pilot light

Thermostat

housing

Titanium anode

Ceramic element,

enamel plated sheath

and housing

Installation of the heater

IMPORTANT

● Put the water heater where it is protected from

frost.

● Position it as close as possible to the most fre-

quently used taps.

● If it is installed in an uninhabited room (store-

room, cellar, garage) the pipes should be insula-

ted. The continuous ambient temperature

around the water heater must not exceed 40°C.

● Make sure that the wall-bracket is strong

enough to carry the weight of the water heater

when full of water.

● Allow 500 mm of space in front of each elec-

trical equipment for periodic maintenance of the

heating element.

●

Install a retention tank under the water heater

if it is placed inside a false ceiling, in the attic, or

above inhabited rooms. An outlet connected to

a drainpipe is necessary.

● The applicable standards and national regula-

tions on fitting, plumbing and electrical connec-

tions must be implemented on installation.

Example

Installing a vertical wall-mounted water heater (VM)

Handles are built into both ends to facilitate handling.

Several attachment types are possible depending on the nature of the wall :

A) Thin walls (plasterboard partition).

ø 10 mm threaded rods passing through the wall connected by sections or plywood panels.

B) Thick hard walls (concrete, stone, brick)

Grout in ø 10 mm bolts or drill holes to fit ø 10 mm MOLY type inserts.

C) Vertical wall-mounted water heaters may be placed on a tripod when the partition can-

not support the weight of the heater. An additional upper stirrup attachment is compulsory.

Use the tripod recommended by the manufacturer.

Use the attachment template printed on the packaging box for both types of walls

and check the centre distance of the holes.