• The juice will ow dir

collected in the pulp jug (12),

• The stopper in the outlet opening may be closed for a short time to

change the juice container and after the operation is completed to

prevent dripping of the juice leftovers,

• If the worm-scr

device will start operating after a while and the switch will start

ashing) for 3 to 5 seconds. If the problems r

process 2 to 3 times and then turn the device and disassemble

the elements of the juicer (see the CLEANING section) to remove the

blocking element.

• After all pr

stopped, turn the device o and wait until it stops.

Observe the times of continuous operation. Exceeding the operation

time and failing to ensure sucient br

irreversible damage of the motor

GUIDELINES

Use fresh fruits and vegetables because they contain mor

• Thor

• Rr

stones and hard seeds fr

• Divide the pr

in the lid (2). Long (e.g. carrots) or br

divide into shorter/smaller pieces,

• Pr

in small portions of approx. 0.5 kg. Befor

turn the device o and disassemble the elements for cleaning (see:

CLEANING).

• Do not pr

• When juicing herbs or leafy

them together making a packet or combine with hard pr

• The device is not suitable for juicing long br

stems (e.g. stems of parsley)

• Apple juice darkens very quickly

adding a few drops of lemon juice,

• Pr

them as the rst or the second ingredient. Banana nectar will ow

with the juice from other fruit,

• The device is not suitable for juicing very har

vegetables, e.g. sugarcane,

• T

of dierent consistency rst pr

ones

CLEANING INSTRUCTIONS

After processing pr

this purpose, during operation pour pure water into the inlet in the

lid (2). If you change the processed pr

mixed) preliminary cleaning lets you rinse the juicer without having to

disassemble the whole device. When the device is not in use or before

thorough cleaning, disconnect it fr

clean the device just after use. Do not use abrasive cleaners, cleaning

powders, acetone, alcohol, etc. to clean the device. All removable parts

are dishwasher safe when placed on the top shelf. Make sur

placed away from the heater

Before cleaning, turn the device o, pull the plug out of the socket,

then disassemble the juicer elements in the following order:

• Remove the pusher (1),

• Release (turn to the left) and remove the lid (2),

• Remove the juicer jug (5) fr

vigorously

W

brush (14) and rinse under running water

before r

cloth. Never immerse the body in water or rinse under running water

TROUBLESHOOTING

If any irregularities ar

the information below to identify the cause and solve the problem.

No power in the juicer

Make sure that the power cor

Make sure that the lid of the jug (2), the jug itself (5) and the worm-

screw (3) ar

elements are not pr

Small volume of the obtained juice

The volume of the obtained juice depends on the water content in the

ingredients, which may vary

smaller if the ingredients ar

Make sure that the rubber insert (8) is tightly fastened. If an ingr

contains little water

squeezed ingredient is small and has soft seeds, extrusion of several

portions may gradually decrease the volume of the obtained juice. T

obtain as much juice as possible, disassemble and wash the upper

element of the device (2,3,5) in the intervals between the extrusion

stages. The performance of the device and the overall amount of the

obtained juice may be aected by the seed residue deposited at the

bottom of the sieve.

The juice contains too much pulp

The obtained juice may contain ne pulp, which largely depends on

the type of ingredients. T

frequently clean the juicer jug (5) along with the worm-scr

starting the next stage of extrusion.

The volume of pulp varies depending on the type of ingredients.

If the deteriorated performance of the device results fr

screw (3) damage r

* The shelf life of individual parts may vary depending on the manner of

use and the squeezed ingredients.

The device lid cannot be closed

Make sure that the worm-scr

juicer jug (5). This will allow to properly close the lid.

Closing the lid may cause problems when the slot at the bottom of

the worm-screw is not thor

ingredients.

Unusual noises during the juicer operation

Make sure that the parts ar

parts and check whether the device still makes strange noises.

Do not use the juicer unloaded i.e. without ingredients or liquid. T

the juicer on without ingredients may cause damage to the worm-

screw

The sound of friction coming from the worm-scr

after putting ingredients into the juicer

loading the ingredients, check the size of ingr

ingredients do not exceed the thickness of 2.0 cm for an individual

ingredient. The size of ingr

type of ingredient. The device can operate louder

surface. Always place the juicer on an even horizontal surface.

The juicer stopped working during operation

Check the power cord and make sur

Check if all parts are pr

stop the device If the juicer has stopped due to overloading with

ingredients, pr

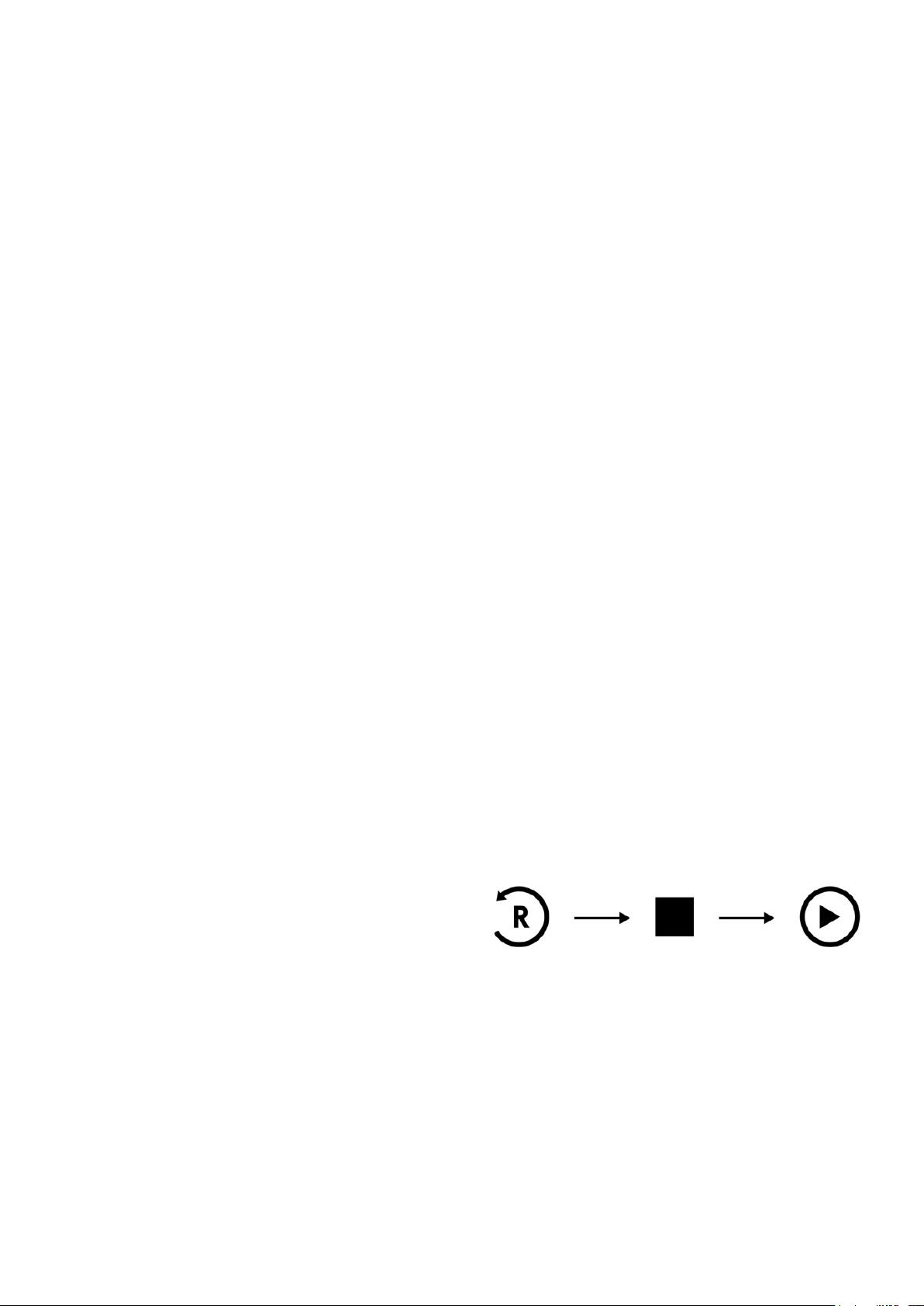

in the given order

position causes the ingredients to be pushed back up. The button in

the “PLA

If the juicer has stopped working as a result of overloading, befor

restarting leave it for 1 to 2 hours to cool. Remove har

ingredients befor

the juicer

The juice container shakes during operation

The worm-screw (3) r

ingredients is set in such a manner that working causes vibrations. The

upper part may fall into higher vibrations if ingredients containing har

bres ar

The juice is not homogeneous

Depending on the density of ingredients, sometimes layers ar

in the squeezed juice. The process diers fr

when preparing juices in high-speed juicers.