19

ENGLISH

1. GENERAL

1.1 Opera

This operating manual pro

eicientoperationandshouldformab

involving the machine. It is an integr

which should be kept in the immediate vicinity ac

for its operating per

adherence t

Therefore, bef

read car

Moreover

at the site of the machine operation and g

regulations must be c

1.2 E

Warnings and safe

Warnings and safe

identiedwiththepictogramsandpr

highlighted in grey

DANGER

... draws attention t

not avoided, may result in heavy or even f

A

... draws attention t-

tions that, if not avoided, may result in material damage.

… marks danger due to electric current.

Failur

danger of heavy or f

… marks danger of crushing.

Failur

danger of heavy injuries fr

… marks danger due to hot surfac

Failur

danger of burns and heavy skin injuries c

… marks danger from moving diamond blades.

Failur

danger of cuts and heavy skin injuries c

diamond blades.

1.3 Liability limita

All data and instructions provided in this manual w

compiled with c

andregulations,st

long-standing insights and experienc

The manufactur

caused by:

-

-

-

-

-

-

The responsibilities agreed in the delivery contr

General T

conditions of the manuf

regulations v

contr

Warr

The manufactur

of the applied process t

par

with the defect

Warr

12monthsaerdeliveryofmechanicalandelectrical

componentsforone-shioper

parts and tools.

The warranty claim e

and started up by our e

The warranty e-

quential damages are ex

Damagecausedbynatur

maintenance, f-

tions, exc

shall be excluded from the w

2. SAFETY

2.1 Intended use

The P-3510, P

is designed for wet cutting of the solid c

materials such as: Clinker

refract

tiles and cer

-

are excluded.

-

unintended use.

2.2 Rationally f

Any use of the machine going beyond the intended one,

shall be deemed unintended and thus prohibited.

This also applies to:

-

-

-

-

(vertical plunging into chippings from abo

2.3 Responsibilities of the oper

Operat

An operator is every natur

machine or delegat

for the safety of the user

course of such use.

Operat

The machine is used in the commercial sect

the operator of the machine is subject t

obligations re

The operator

-

regulations.

-

additional dangers resulting.

-

operation.

-

machine, whether the oper

by the operat

and regulations.

-

operation, maintenanc

clear¬ and unambiguous manner

-

have read and under

Moreover

handling the machine at regular intervals and be

informed about potential danger

-

with the prescribed and rec

devices.

-

the machine is always in a technically perf

-

intervals, and that all safety mechanisms of the

machine are regularly c

functionality

2.4 Personnel r

Fundamentals

Any operation with the machine may only be carried out b

the persons, capable of perf

reliably and meet every requirement mentioned.

-

responsecapabilityisa

medicines.

-

always adhere to the applic

specicregulations.

WARNING:

Risk of injury for

Improperoperationc

material damage.

Any operations must be only carried out b

having required tr

Qualied electricians

As a matter of principle, all works on the electrical

installationsmustbecarriedoutbyqualiedelectricians.

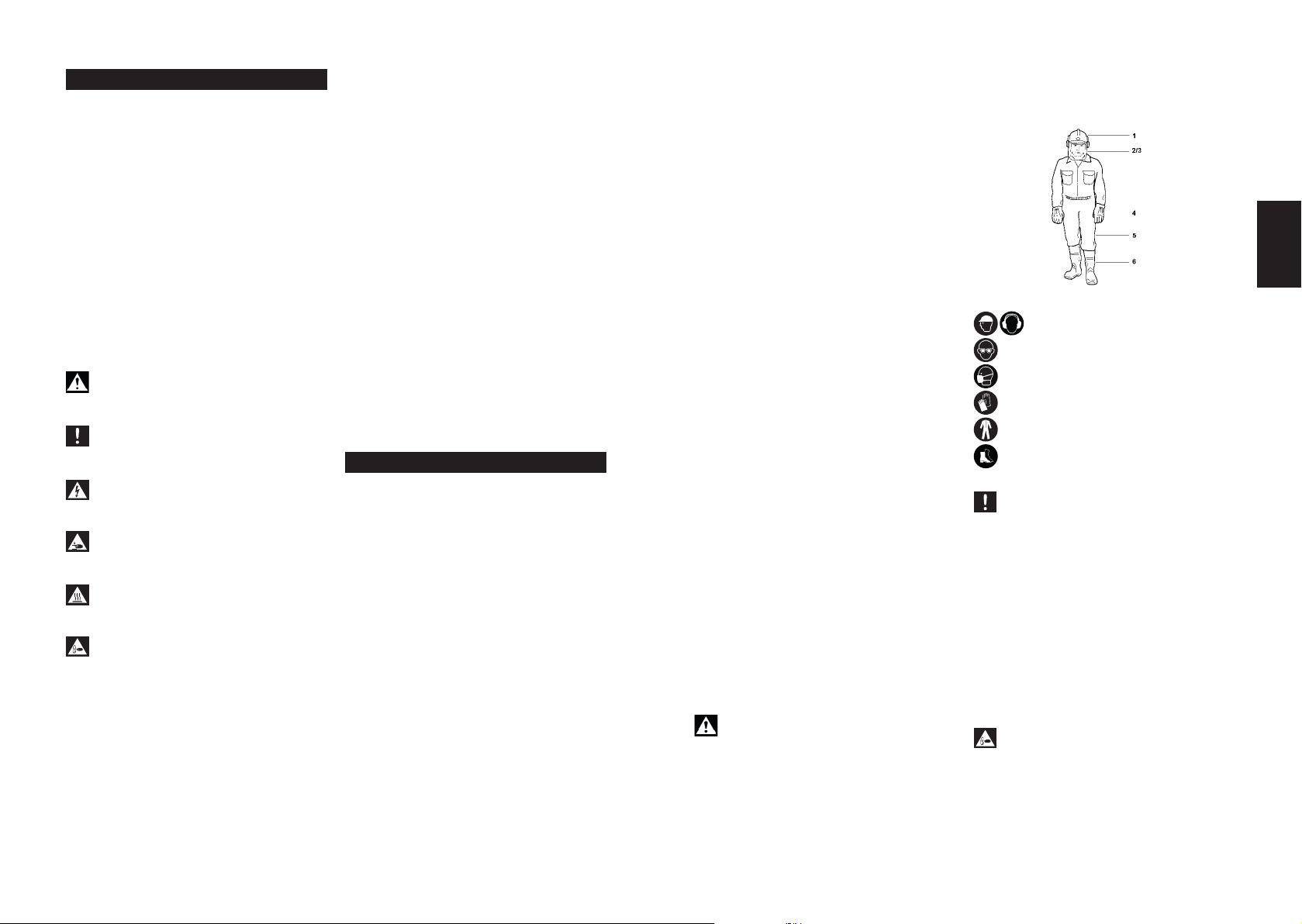

2.5 Personal pr

Wearing personal prot

the work.

1. Helmet with ear pr

2. Visor or prot

3. Dust mask / respir

4. Safe

5. Suitable pr

6. Protectiv

NOTE!

It is prohibited to we

rotating p

dangercre

the intended protection.

2.6 Dangers

The machine has undergone a risk review

theidentieddangerswer

Nevertheless, the machine poses residual risks described in

the following section.

-

here and in the chapters about handling¬ t

damage to he

2.7 Risks

CAUTION!

Risk of cut injuries!

Reaching into r

-

circumstanc

-

-

-