10

+ Check the tightness of all screw connections once a month.

+ In order to be able to guarantee the constructively dened safety level of this

equipment, we recommend having the equipment regularly maintained (at least

once a year) by specialists (service technicians of your contract partner).

+ The equipment may be cleaned of dust, dirt and sweat using a damp cloth. The

use of solvents should be strictly avoided. Also, make sure that no liquids (e. g.

sweat) get into the openings of the equipment (e. g. console).

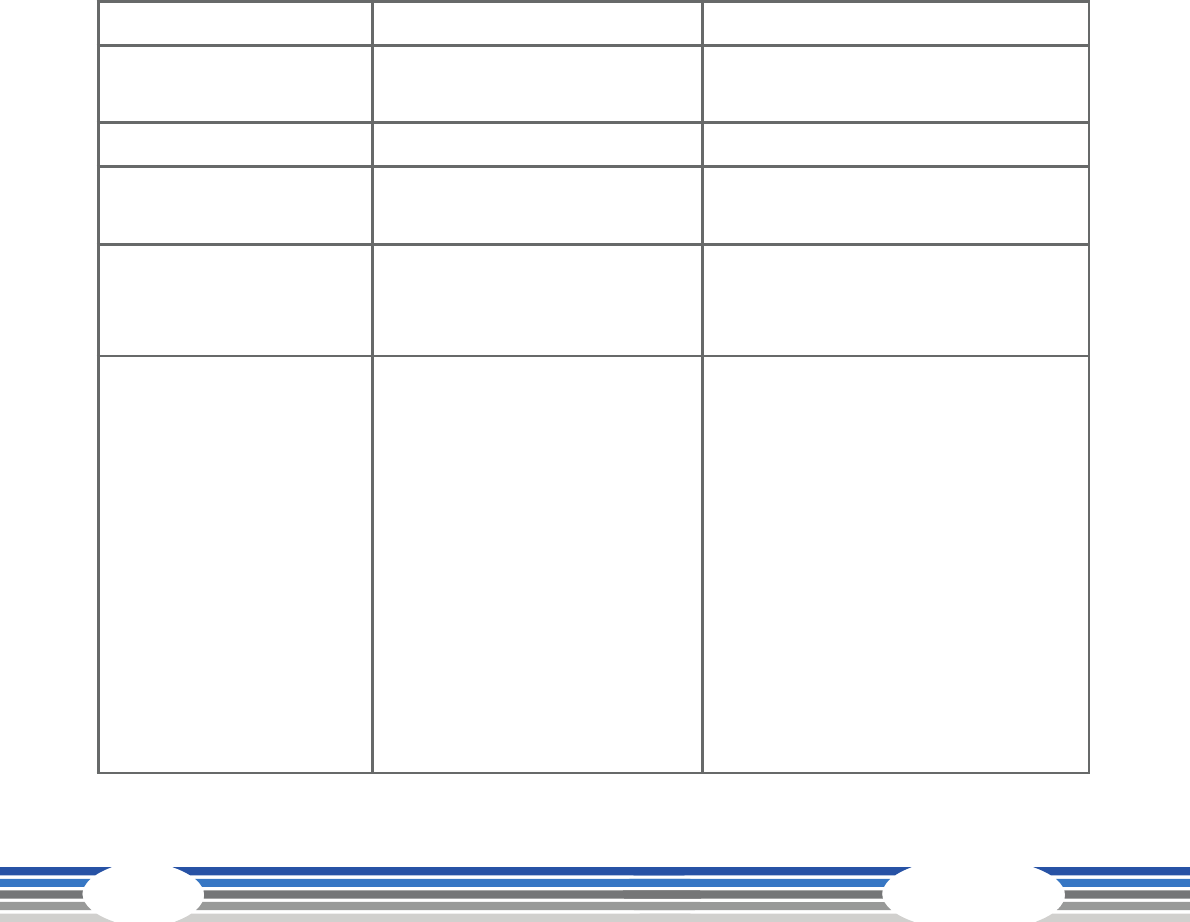

2.2 Faults and Troubleshooting

The equipment runs through regular quality controls during production. Nevertheless,

errors or malfunctions on the equipment may occur. Individual parts are often the

cause of faults and replacement is usually sucient. Please use the following overview

to see the ve most common errors and how to repair them. If the equipment still

does not work properly, please contact your contract partner.

Error Cause Repair

Crackling noise in

pedal area

Loose pedals Tighten the pedals

Equipment wobbles Equipment is not level Adjust the supporting feet

Handlebar/saddle

wobbles

Screws are loose Tighten screws

Display doesn‘t turn

on

Power is disconnected Check all screw connections

and see if the plug is plugged

in

No pulse reading • Interference in the room

• Using a chest strap:

- unsuitable chest strap

- chest strap is

incorrectly positioned

- batteries are empty

• Eliminate sources of

interference (e. g. mobile

phone, loudspeaker, etc.)

• Use a suitable chest strap (see

recommended accessories)

• Reposition the chest

strap and/or moisten the

electrodes

• Change the batteries