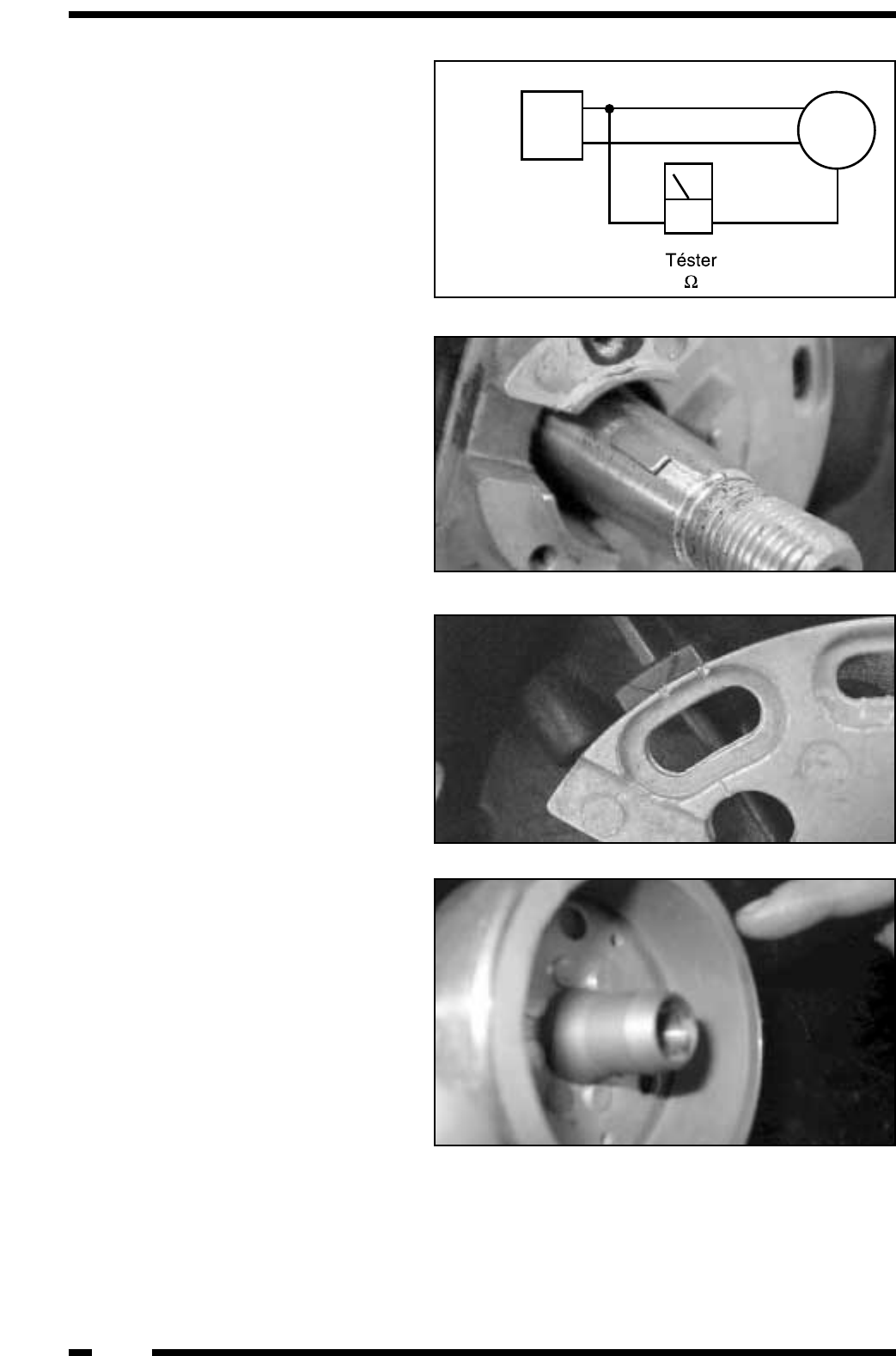

- Rotate the magneto rotor by hand,

taking it through one complete revo-

lution of 360º, and observe whether

the tester shows a very high resis-

tance reading throughout the grea-

ter part of the revolution (open cir-

cuit), and gives a very low reading

(closed circuit / continuity) during a

very short part of the revolution. If

this does not occur, this is a sign of

a fault and the magneto should be

replaced.

- In the event of a fault, the entire

faulty component as identified

through the procedures indicated

above should be replaced.

- Proceed to re-assemble the unit,

taking special care to check the

condition of the key at the end of

the crankshaft. If it shows any signs

of damage, it should be replaced.

- In order to be able to synchronise

the ignition timing correctly, when

assembling the coil base plate onto

the engine crankcase, take care to

ensure that the reference mark on

the magneto coil base plate is alig-

ned with the centre of the arrow on

the crankcase.

- Re-assemble the magneto coil unit

onto the magneto coil base plate,

using special immobilising tool (part

reference number 00G05300011) to

prevent the part from rotating.

Check that the magnet in the inte-

rior shows no signs of breakage or

of damage: in the event that dama-

ge is found, it should be replaced.

Tighten the securing screws to the

recommended torque setting. The

setting of the ignition timing does

not require any maintenance.

Ensure that the electrical cables in

the unit are correctly routed to avoid

any possible chafing, which could

lead to later damage and failures.

16-4