10

Installation

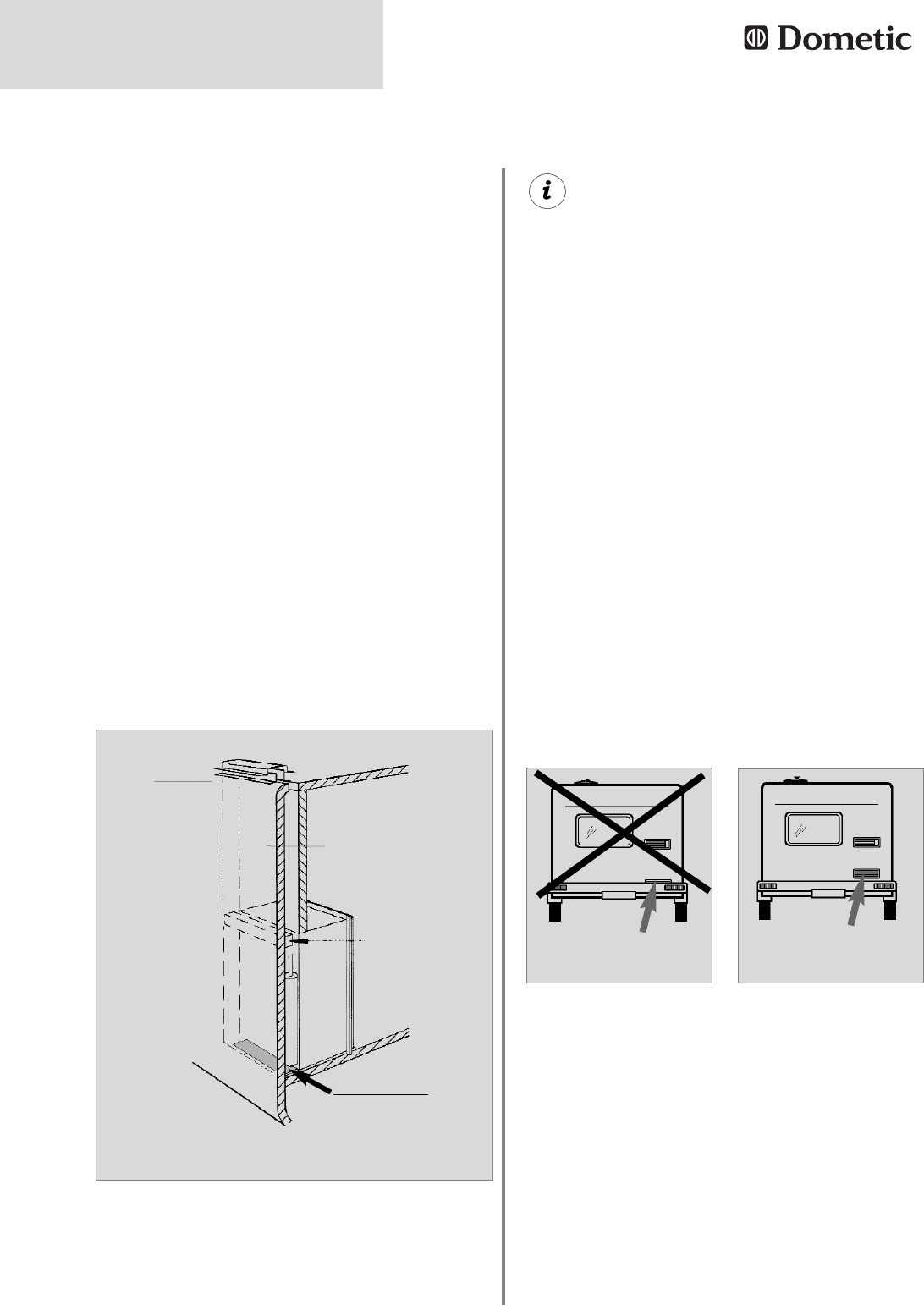

Fig. 7

floor opening:

at least 50 mm wide,

at least 520 mm long

hot air

condenser

Recommendation:

Roof vent

R500

Proper ventilation of the refrigerator can also be

achieved by lower air intake aperture in the floor

and upper roof exhaust vent (see Fig. 7). A flue

has to be provided between the top edge of the

refrigerator and the roof ventilation which

directs the hot air and the exhausts straight to

the air vent in the roof.

The floor opening must have a cross section of

at least 250 cm² . Protect the opening, e.g. with

a baffle plate and a net, to prevent dirt from

entering the gas burner. Compared to side ven-

tilation, this ventilation method can allow more

dirt to enter the rear area of the refrigerator,

which makes regular maintenance of the gas

burner, at least once a year, necessary.

With this installation method, regular main-

tenance of the gas burner is only possible

once the device has been dismantled. It is

imperative that the refrigerator be installed in

a way to allow easy removal.

We therefore recommend providing an ade-

quate access opening (service flap) for ready

serviceability from the outside.

4.1.2 Side installation with floor-roof

ventilation

Another unfavourable method of rear installation

is to install the air intake and exhaust grilles (Fig.

10) at the side wall of the recreation vehicle. The

air-heat recirculation is very restricted which

means that heat exchangers (condenser, absor-

ber) cannot be adequately cooled. The optional

method of an additional air vent grille installed in

the floor also exhibits an insufficient air flow

duct.

4.1.3 Rear installation

Rear installation often causes an unfavourable

installation arrangement, as ideal ventilation

cannot always be assured (e.g. the lower venti-

lation grille is covered by the bumper or the rear

lights of the vehicle!) (Fig. 8). The maximum coo-

ling performance of the aggregate is actually not

available.

Fig. 8

Fig. 9

Air vent grille not

blocked ! OK!

Air vent grille

blocked !