20

Ventilation and extraction

A correct installation is important for correct operation of the appliance to ensure,

there is no build-up of heat at the back of the appliance. This heat must be allowed

to escape into the open air.

In the event of high ambient temperatures, full performance of the cooling unit

can only be achieved by means of adequate ventilation and extraction.

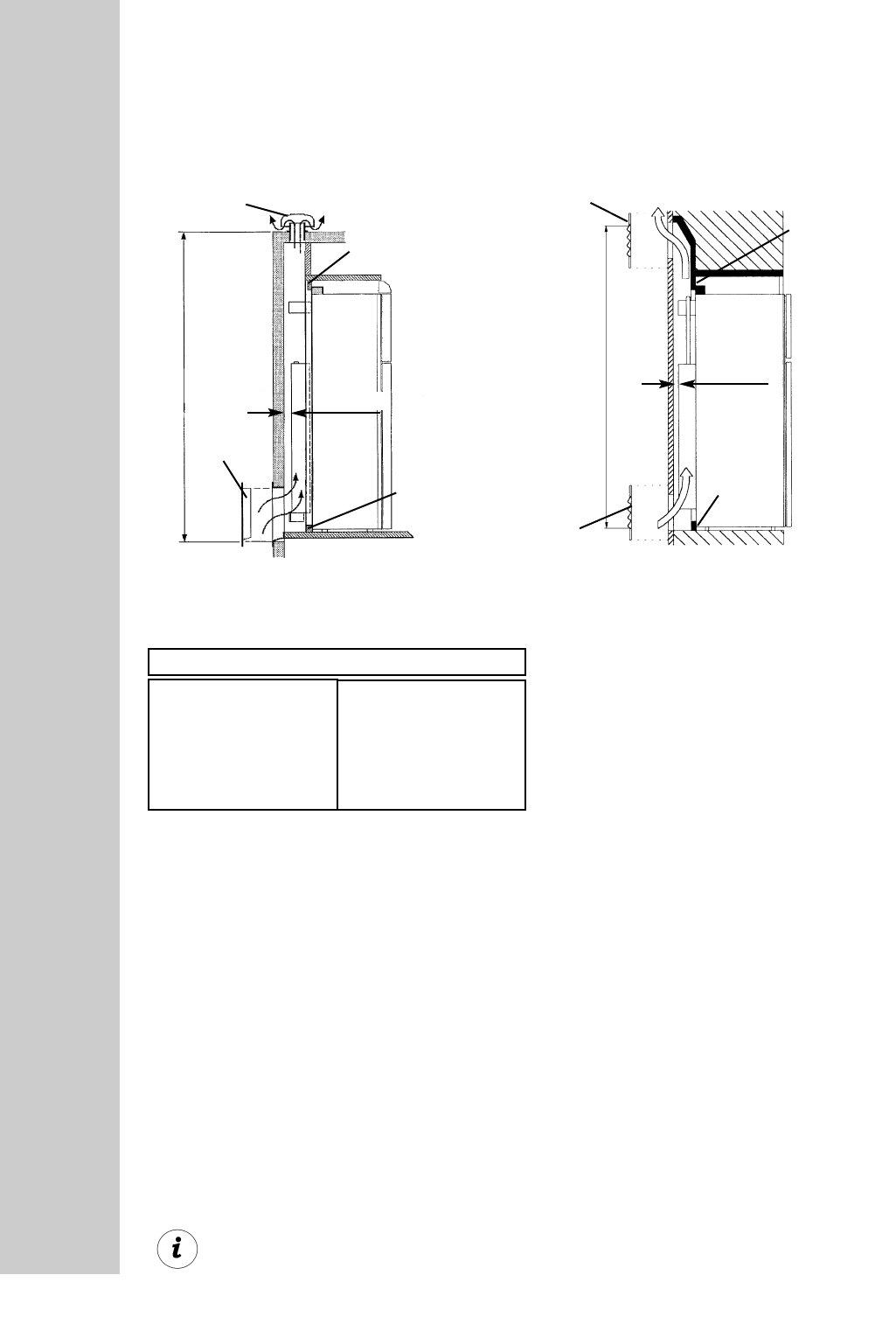

6.3

Correct mounting of the lower ventilation grille facilitates the access to

the electrical and gas connections during maintenance work.

Installation of lower and upper ventila-

tion grilles (L500).

Installation of lower ventilation grille

(L500/L300) with roof exhaust (R500).

L500

L500

10-20mm

Stopper

strip with

profiled

joint

Stopper

strip with

profiled

joint

Stopper

strip with

profiled

joint

Stopper

strip with

profiled

joint

Minimum height of ventilation

Minimum height of ventilation

L500

R500

10-20mm

Minimum height of ventilation ( mm) H

The unit is ventilated through openings in the wall or roof of the vehicle.

(Fig. 1 and Fig. 2). Fresh air enters at the bottom and the warmed air flows off

through the upper ventilation grille (flue effect). The side walls of the ventilation

shaft should be local to avoid the build up of condensation and drafts. The parts of

the shaft walls, which are situated above and next to the exhaust for the combus-

tion gases, must be made of non combustable material. The upper ventilation grille

should be positioned as high as possible above condenser (A) (observe minimum

ventilation heights). The lower ventilation grille should be flush with the floor of

the vehicle, allowing any gas leakages (heavier than air) to escape directly into the

open air. If such an arrangement is not possible a hole must be provided by the

manufacturer of the vehicle under the refrigerator (not close to the burner) so that

any leaking LP gas can escape. This must have an effictive area of at least 13cm².

It is desirable to fit the hole with wire mesh or similar, and an angle plate to protect

it from stones, mud etc., the wire mesh must not reduce the effective area of 13cm².

The ventilation grilles must have a free cross section of at least 400cm

2

. Here

it should be noted that protective insect nets behind the ventilation grilles can redu-

ce the free cross section by up to 50%.

Fig.2

Fig.1

A.

☺☺☺☺☺☺

Roof exhaust R500

Lower ventilation

L500/L300

1250

B.

☺☺☺☺

Upper ventilation and

Lower ventilation

L500/L300

1400

H

H

A

A