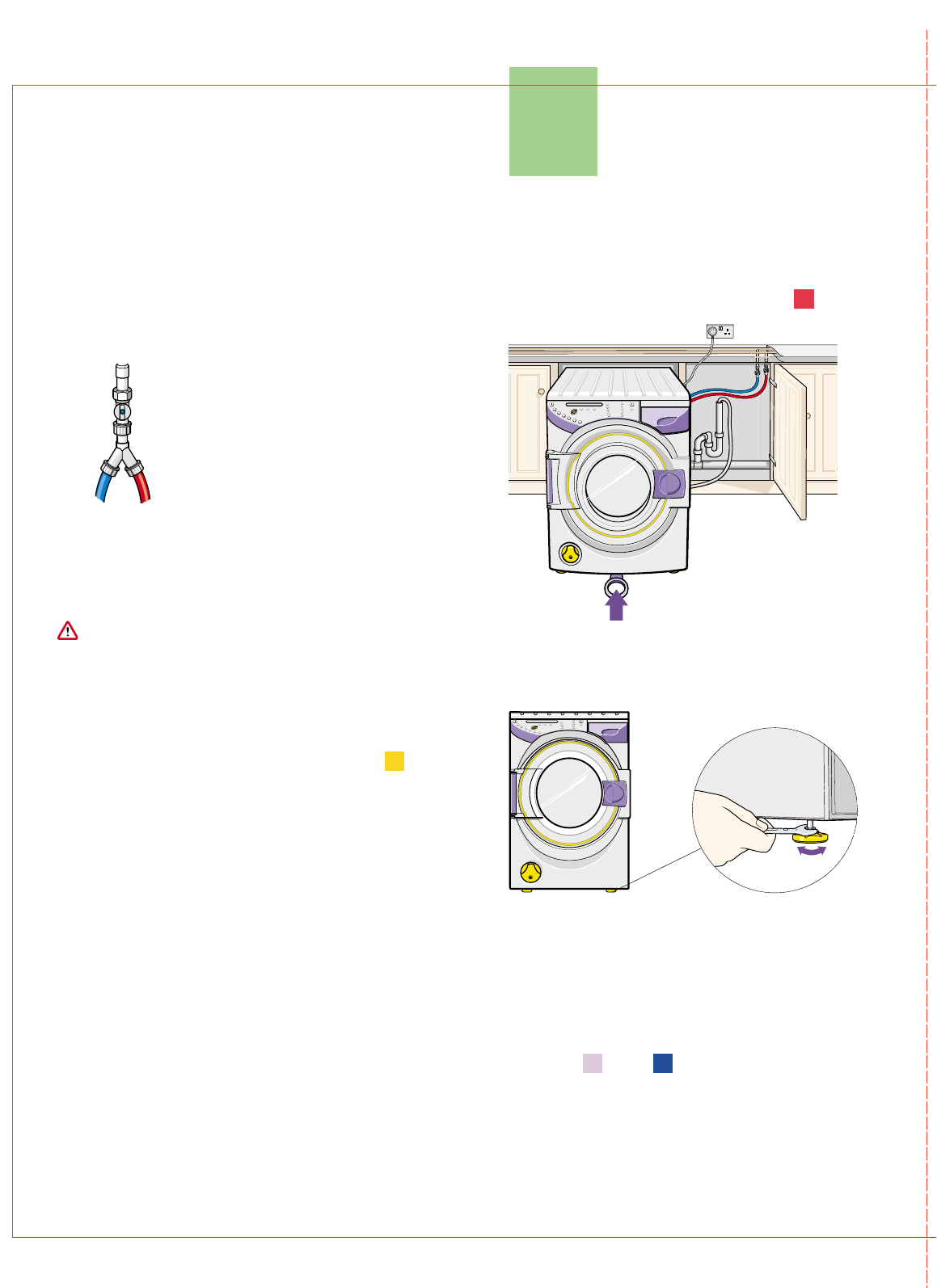

When all the instructions on the previous pages have been

completed, the machine can be installed into its operating

position using the Rollerjack

TM

handle (see section 4 01).

• Using the Dyson spanner, adjust the two front feet so that the

machine is perfectly stable and will not rock on three of its

four contact points.

• Do not use wood, carpet or other material to stabilise the

washing machine.

After installation

• Run an empty 60ºC cotton cycle with a half measure of

detergent. For the correct dosage, please follow the

manufacturer’s instructions on the detergent packaging.

See sections 7 01 and 8 01 on how to start the machine.

• This will clean any test water out of the machine, and ensure

the machine is installed and levelled correctly.

• Observe it regularly during the first wash and check

connections afterwards and during the first week, to ensure

that they have been fitted correctly.

Cold water only supply

• If there is no hot water supply, attach the cold and hot hoses

to the machine as normal. Then, attach both hoses to a

Y-piece (which can be ordered from the helpline) and finally

connect the Y-piece to the cold inlet tap.

*Note: CRO1 Flowcheck and Memory have grey leak protection inlet hoses

• Once all connections have been made, turn on the tap(s) to

check that there are no leaks.

Electrical installation

Warning: This machine must be earthed

• Any electrical work required to install the washing machine

should be carried out by a qualified electrician.

• Before using your machine, check that the plug and sockets

match, and check that the voltage in your home corresponds

to the machine’s voltage.

This information is on the rating plate (see section 1 01).

• The machine should be plugged into an earthed socket

which can be switched on & off, and that is easily accessible

after installation.

• Do not use an extension cord or plug adapter.

• If the supply cord or plug are damaged disconnect the

machine from the socket outlet immediately. The supply cord

must only be replaced by Dyson or its appointed agents, as

special purpose tools and service techniques are required.

• If the plug supplied needs to be removed it should be cut off

and safely disposed of. Under no circumstances should the

severed plug be inserted into a socket outlet as this will

present an electric shock hazard.

European conformity information

This Contrarotator

TM

has been tested and conforms to the

following European Directives:

73/23/EEC Low Voltage Directive.

93/68/EEC CE Marking Directive.

89/336/EEC EMC Directive.

Installation

5 03