6.2. Do not touch the stove while your hands are wet. Though the stove is equipped with ground plug, it remains

an electric machine that could cause electric discharge if handled incorrectly. A qualified technician only shall

resolve the eventual problems.

6.3. Do not remove any screw of the zones exposed to high temperature before they have been lubricated properly

with lubrication oil.

WHAT DO TO IF...

THE STOVE REMAINS OUT OF POWER:

6.4. Make sure the stove is connected and the plug is leading power.

6.5. Make sure the cable is not damage or cut.

While the stove is disconnected, dismantle the right side of the stove and check if any lead of the C.P.U. is

slack.

6.6. Check the C.P.U pilot. If it is OFF, check also the fuse on the C.P.U.

PELLETS DO NOT FALL AND THE STOVE DOES NOT TURN ON:

6.7. Check if there are pellets in the hopper.

6.8. Make sure the glass door is closed.

6.9. Make sure the gas outlet tube is not obstructed by anything (e.g. bird nest, plastic, etc.).

6.10. Make sure the exhaust motor works, because if it does not work fuel will not fall.

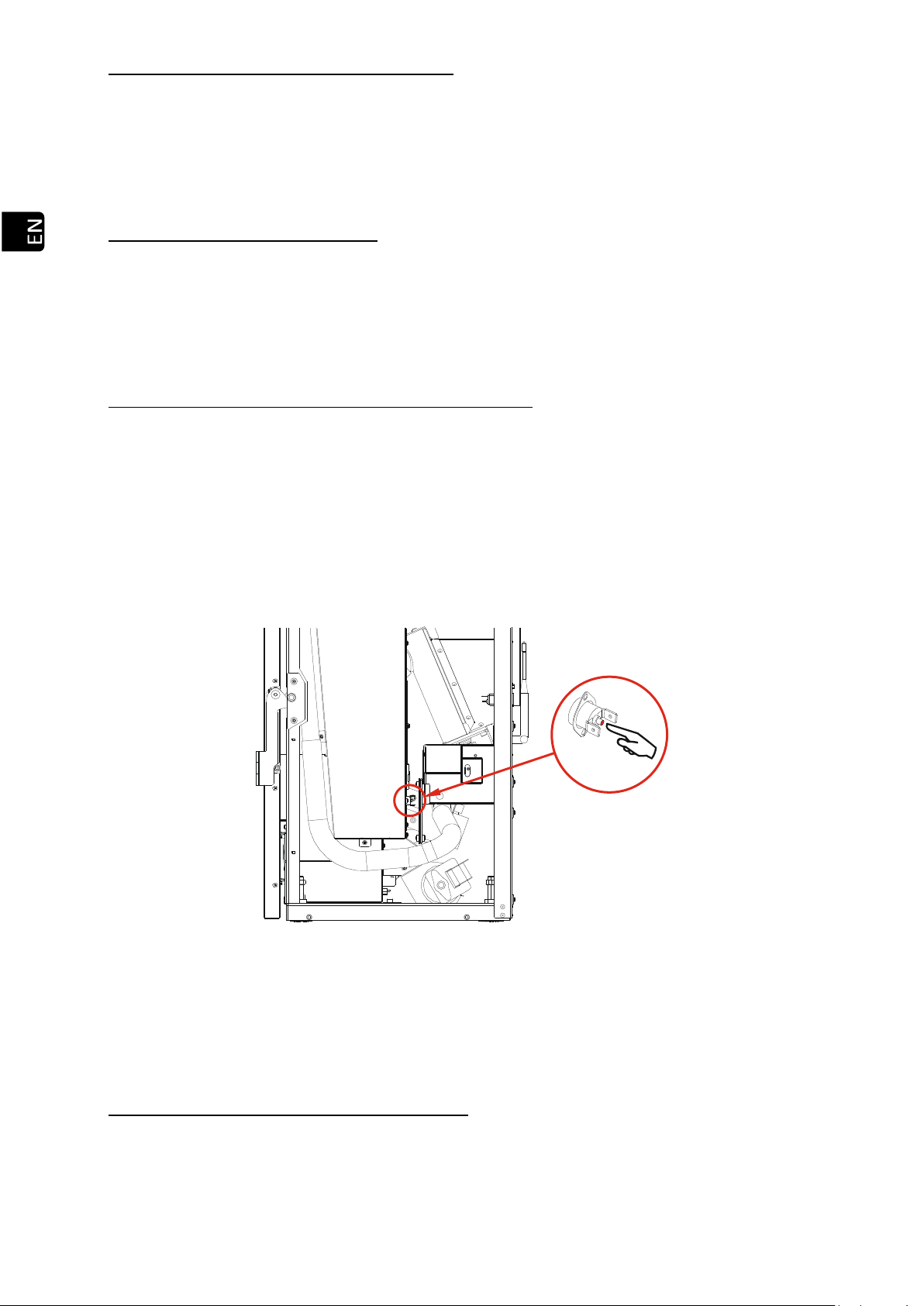

6.11. If the reducer motor does not rotate and the displays indicates the pulses, the first thing to do will be unplug

the stove and verify if the safety thermostat has been activated. With the stove unplugged, check that the

safety thermostat is located inside the stove, by opening the right side. To activate it, you must press the

button. If the thermostat is activated you will hear a “click”. If the safety thermostat had been activated before,

consult your dealer.

Drawing 27

6.12. If the reducer motor receives current and rotate slower than usually, it may have something blocked such as a

screw, a piece of wood, etc. To solve this problem, you must empty the hopper and, even if necessary, to

remove the auger screen.

6.13. If when the reducer motor rotates makes a noisy is due to a lack of lubrication- you have to lubricate only the

auger screen, not the reducer motor, see point 5.9.

PELLETS FALL BUT THE STOVE DOES NOT TURN ON:

6.14. Make sure the glass door is well closed.

6.15. Make sure the burn pot is correctly placed, that it is in contact with the resistance tube and the central hole of

the burn pot goes along with this tube.