8.4 Adjusting the height of the table

Ȝ Slacken the tightening screw (6).

Ȝ Move the table (7) to the required position by

lifting or lowering and turning to the left or right

as required.

Ȝ Position the table (7) so there is still a big

enough gap between the workpiece and the tip

of the bit for you to start up the drill in idle.

Ȝ Re-tighten the tightening screw (6).

If you want to drill a hole all the way through the

workpiece, make sure that the hole in the table (7) is

centrally positioned relative to the bit.

When working with large workpieces you can swing

the table (7) completely to the side in order to place

the workpiece directly on the base plate.

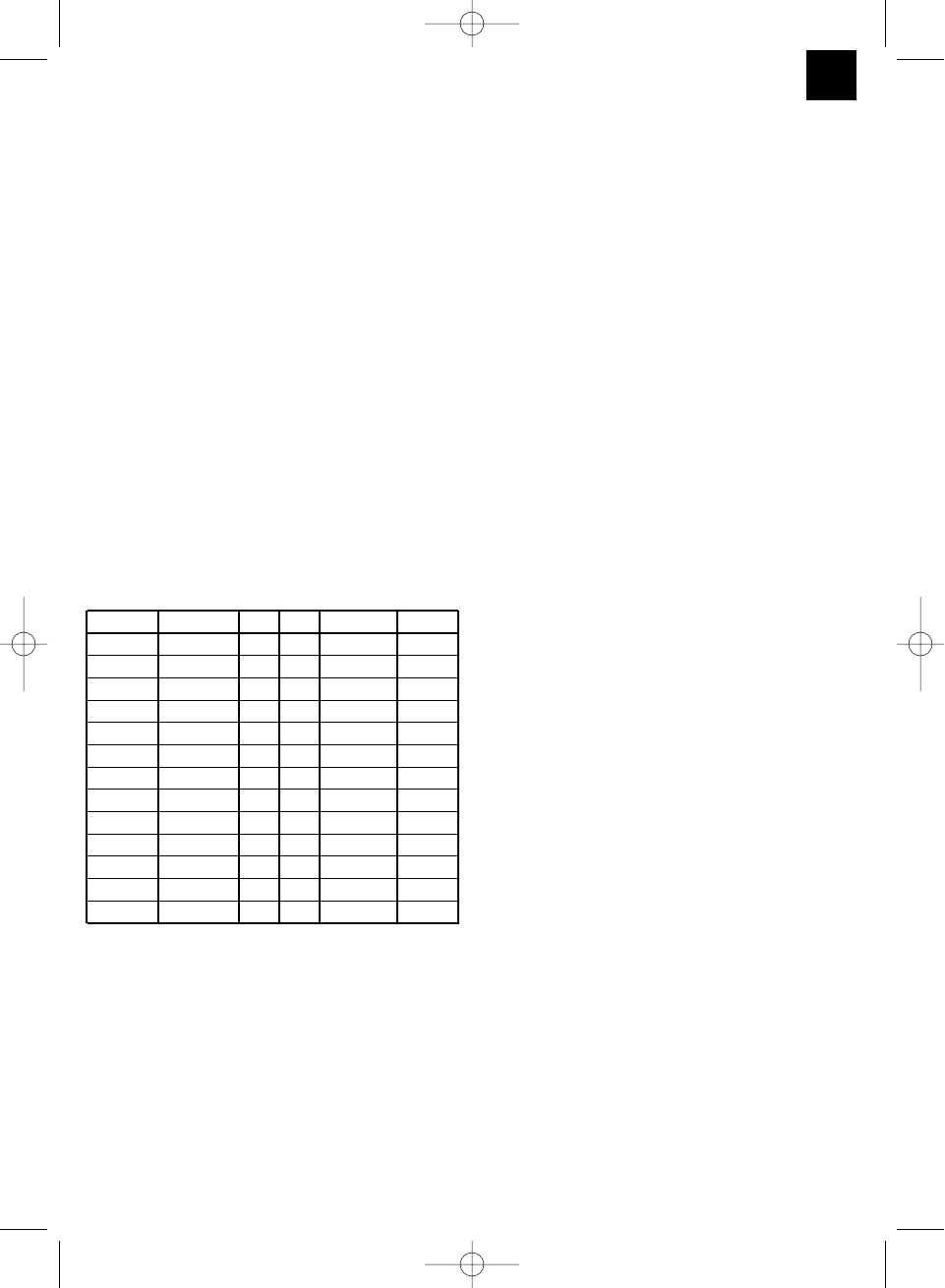

8.5 Speed table

The list below will help you select the right speed for

various materials.

The speeds quoted are guidelines alone.

Bitdiameter Gray cast iron Steel Iron Aluminium Bronze

3 2550 1600 2230 9500 8000

4 1900 1200 1680 7200 6000

5 1530 955 1340 5700 4800

6 1270 800 1100 4800 4000

7 1090 680 960 4100 3400

8 960 600 840 3600 3000

9 850 530 740 3200 2650

10 765 480 670 2860 2400

11 700 435 610 2600 2170

12 640 400 560 2400 2000

13 590 370 515 2200 1840

14 545 340 480 2000 1700

16 480 300 420 1800 1500

9. Maintenance

There is no need to lubricate the bearings of the SB

401. All the ball bearings are greased for life.

Lubricate all moving parts and threads regularly with

a drop of acid-free lubricating oil.

Use only a brush or rag to clean the machine.

Never use solvents to clean the painted parts.

Treat bare parts regularly with anti-corrosion agent.

10. Ordering replacement parts

Please quote the following data when ordering

replacement parts:

Ȝ Type of machine

Ȝ Article number of the machine

Ȝ Identification number of the machine

Ȝ Replacement part number of the part required

9

GB

Anleitung SB 401-12 sprachig 07.11.2001 7:58 Uhr Seite 9