Mercury Cooker Hoods: PC1000/1082/1100/1200

Revision: 22/11/

2

ENGLISH

SECTION 1. INTRODUCTION

Your range cooker is a semi-professional unit which gi

potential in the kitchen. Inevitably, during the cooki

produced. Your Falcon extractor has been designed to complement the ran

performance in order to create the ideal environment for creative

SECTION 2. EXTRACTION PERFORMANCE

The most important influence on the performance of

takes the exhaust air from the extractor to the outside wall lou

consideration during the initial stages of the

•

The extractor is provided with a spigot suitable for

•

Note: 150mm is the minimum duct diameter consi

•

The exhaust duct route length should be kept as shor

•

The most efficient configuration is to duct straight through an outside

cooker against an outside wall when designing your kitchen layout

•

The hood can be vented either to the top exhaust or the re

which gives the shortest duct route length and least number of bend

rotated for ducting directly through the rear exhaust p

•

A route with more than two 90 bends will significantly degrade the performance of the

system. If possible, avoid having a 90 bend at the extractor

large as possible to maintain a smooth airflo

flexible ducting taut over straight runs to ensure that t

SECTION 3. IMPORTANT INFORMATION

The following minimum headroom is required

For a small charge customised replacement chi

The minimum distance between the range hob bur

prevent overheating of the extractor and its

If you are fitting a splashback then the cooker-to-hoo

Please also note that a 90 bend in the flexible ducting will re

smooth radius with no kinking.

Requirements of the relevant authorities

Attention:

This appliance requires an earth connection.

Ensure that the supply voltage corre

The extractor must be isolated from the ele

nance operations.

Pay particular attention to fire risk when frying. To

relating to cleaning the grease filters and removing greas

Do not flambé under the extractor.

SECTION 4. INSTALLATION

4.1 Removing the Grease Filter(s)

Place extractor on its backplate on a horizontal

To remove the grease filters pull/lift the filter release lever away from the hood base. This rel

retaining clips allowing the filter to be carefully lifted away from the hood. T

hood.

The internal fixing holes, blower assembly and spigot

openings in the baseplate. (See Page 7).

4.2 Blower Exhaust Position

The hood can be vented either to the top exhaust or the re

has 4 studs onto which can be bolted either the blower assembly or a bla

Bolt blower assembly to chosen exhaust position and

When changing the exhaust position, care shoul

attached to the blower.

4.3 Duct Installation

Make a hole in the wall or ceiling to take the 150mm diameter ducti

to the outside.

The exhaust duct route length should be kept as shor

Section 2.

Knock a hole in the outside wall to match the inter

4.4 Fixing the Hood to the Wall

If you are fitting a Splashback it must be fitted before

Instructions for mounting the hood are given on page 7

Note: The decorative chimney can be removed to ease handling

The supporting wall must be of good quali

extractor.

Fixings must be used which are suitable

4.5 Connecting the Ducting

Connect ducting to extractor exhaust spigot.

wall. You may find this easier with the chi

screws which can be accessed through the filter opening(s)

When the extractor is in position, check that the duct h

Connect the ducting to the wall louvre spigot or alter

Secure the louvre to the outside wall. Ensure that any air fins are dir

Refit the grease filter(s).

4.6 Electrical Installation

The extractor is a stationary appliance designed to be

A competent electrical technician must perform the el

The extractor must be fed from a 230Vac single phase electrical supply using a

a 3A fuse. The spur should be located adjacent to

nected from the extractor using the switch. The means of di

minimum contact separation of 3mm in all poles. Alternatively a

wiring according to the relevant wiring rules must be fitted.

A supply cord for connecting the spur to the extractor is in

The mains supply is connected to the free end of this cord as f

SECTION 5. OPERATING INSTRUCTIONS

a. Switch power on at the fused spur.

b. The extractor has 6 push-buttons which illu

in the table below.

c. The extractor controller will automatically switch off the appliance

action for 4 hours.

d. After 30 hours accumulated running GREASE FIL

indicators flashing. Reset by pressing Push-button

SECTION 6. MAINTENANCE

Regular maintenance is essential to ensure good p

To clean the stainless steel surfaces of the extractor

abrasive cleaning materials or products.

Clean the grease filters in a dishwasher or b

at least every 2 months - sooner if the extractor is u

To remove the grease filters pull the chrome effect filter relea

releases the retaining clips allowing

taken not to scratch the hood.

To maintain the immaculate appearance of the extractor, and to mini

deposits on the extractor surfaces are

To access the halogen lamps for replace

matt glass with a screwdriver. Only repla

SECTION 7. SPECIFICATIONS

Hood Weights (Approximate)

Cooker-to-hood clearance (min): 800 mm

Hood height including chimney: 511—762 mm

Minimum ceiling height with standard chimney: 2251mm

Warning

Proper care must be taken to ensure that the negative pressures cause

extraction systems do not adversely affect the safe operation of certain types of fuel-bur

appliances (gas, oil or solid fuel), including those i

installed in other parts of the house.

Where such fuel-burning appliances are ins

room of installation, located and sized

extractor does not exceed 4Pa.

In case of doubt, do not operate the extractor and fuel

consult an appropriate (for the fuel type) expert for advice.

The exhaust air must not be discharged into a fl

ances supplied with energy other than electri

fired water heaters, etc.

Adequate ventilation of the room must be provide

supplied with energy other than electricity (e.g. gas-fired or oil-fire

neously. The room must be provided with vents to allow a constan

ELECTRICAL HAZARD

DISCONNECT ELECTRICAL SUPPLY

BEFORE PROCEEDING FURTHER

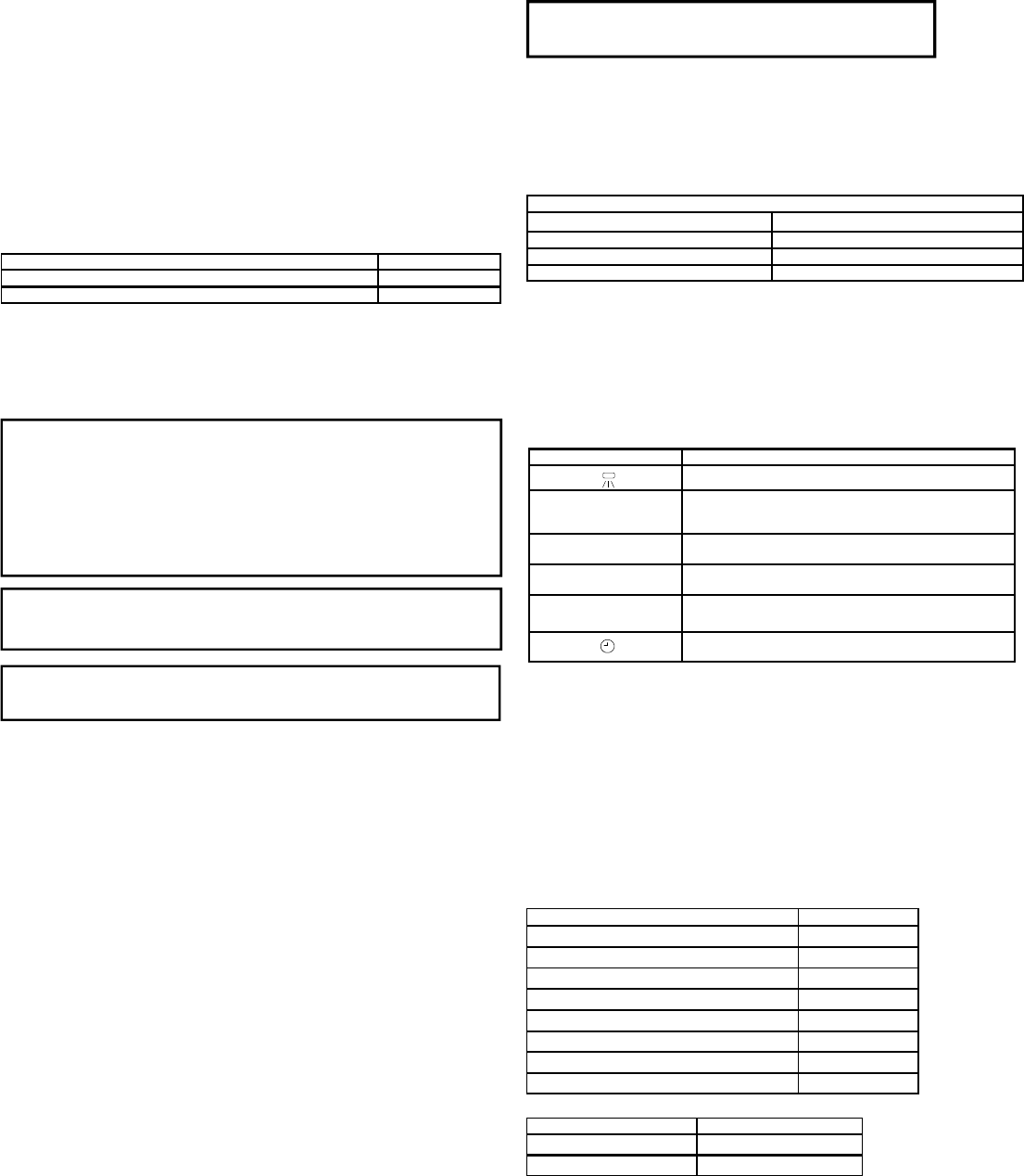

INCOMING SUPPLY CORD CONNECTIONS

Core

Core Colour

Live Brown

Neutral Blue

Protective Earth Green/Yellow

Blower airflo

1000 m

3

/hr

Noise level:

52dBA

Supply voltage:

230V~ 50H

Halogen lamp v

12V

Blower power inp

1 @ 250W

Halogen lamp

2 x 20W

Total power:

290W

Fuse size for

3A

Blower spigot diam

150mm

PC1000

28Kg

PC1082/1100

29Kg

PC1200

29.5Kg

Pushbutton Function

LIGHTS ON/OFF

0 1

FAN ON SPEED 1 (min);

FAN OFF (immediate stop).

2 FAN ON SPEED 2

3 FAN ON SPEED 3

4 FAN ON SPEED 4 (max)

FAN OFF AFTER 10 MINUTE DELAY to clear residual fumes;

indicator flashes during time-out.