GUARANTEE

The guarantee conditions can be found on the separately

enclosed guarantee card.

We declare under our sole responsibility that this

product is in conformity with the following

standards or standardized documents

EN61029-1, prEN61029-2-5

EN55014-1, EN61000-3-2,

EN61000-3-3, EN55014-2

in accordance with the regulations:

98/37/EEC

73/23/EEC

89/336/EEC

from 01-05-2001

GENEMUIDEN NL

W. Kamphof

Quality department

CE

ı

DECLARATION OF CONFORMITY

(

UK

)

Ferm 9

BEFORE USING THE BAND SAW

The saw is for bench use only. Do not use outdoors.

This saw is intended for use on wood, wood derived

products, plastics and soft materials/metals.

This saw must be fully assembled before use.

ASSEMBLING/MOUNTING THE BAND SAW

Make sure the saw is switched OFF and unplugged

from mains.

Refer to parts illustration.

Installing the foot

• Fasten the foot to the band saw base with the four M8

nuts/bolts and washers provided.

• Make sure the long legs of the foot are on the motor

side. Tighten the bolts securely.

Fixing the band saw

The saw should be placed on a level stable non-slip sur-

face; make sure there is enough room round the machine

to operate and service it easily.

• Position the machine and mark the fixing holes with a

pencil. Drill suitable diameter holes.

• Secure the machine with suitable bolts/nuts/washers

through the four holes in the footplate.

• Route the mains cable well away from the saw, ens-

ure that it cannot get caught in moving parts or the

workpiece.

Installing the band saw table

Make sure the saw is switched OFF and unplugged

from mains.

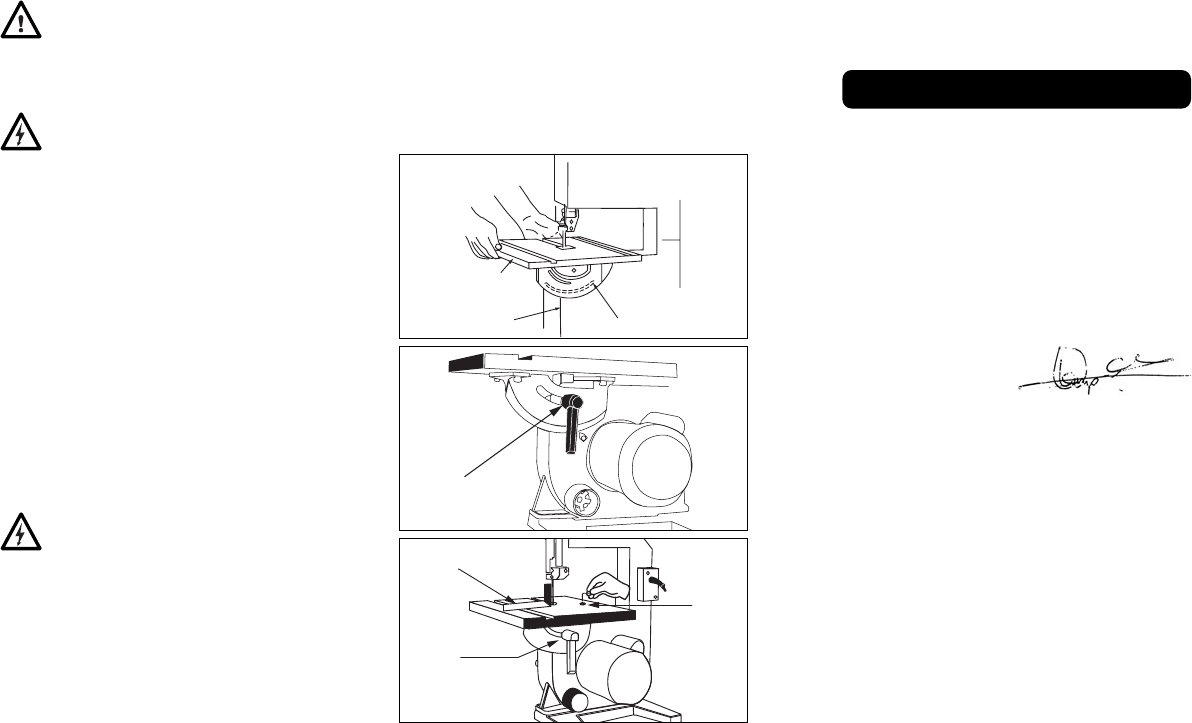

Refer to figs 1,2,3 below

• Remove the nut and butterfly bolt from the end of the

saw slot in the table.

• Put the table onto the saw as shown in Fig 1. Make

sure the groove on the back of the quadrant (C in Fig

1)) fits onto the raised curved lug on the saw body.

• Take the adjusting lever assembly (A in Fig 2)) and

remove the Allen screw and spring with the 4mm

wrench supplied, remove the laver.

• Screw the bolt part of the adjusting lever assembly

with the large washer attached into the threaded

hole in the saw body - hand tight.

• Reassemble the lever, bolt and spring and tighten

with the wrench.

• Tighten the table adjusting screw fully with the lever.

Note: The lever can be pulled out and turned to set it in

the best operating position

Reinstall and tighten the bolt and butterfly nut in the saw

table.

Check the table is square

With the blade guard (4 in parts illustration) raised,

check the angle of the blade to the table with a small set-

square.

• If it isn’t square, from under the table loosen the

adjusting screw lock nut. Loosen the clamp (B) then

adjust the table angle by turning the table adjusting

screw with the 3mm wrench as shown in Fig 3.

• Tighten clamp lever (B) and check the angle again –

readjust a necessary.

• When the table is set at 90 degrees to the blade tigh-

ten the table clamp and set the red quadrant indicator

finger by loosening its screw then lining it up with the

0 degrees mark on the table quadrant (C in Fig 3). The

angles indicated on the quadrant are for indication

only, always check setting by cutting and measuring

on scrap before cutting the job.