Fig.N

Fig.O

Fig.P

Fig.Q

Fig.R

Fig.S

Fig.T

Fig.U

Fig.V

Fig.W

Fig.X

Fig.Y

Fig.Z

Fig.AA

Fig.BB

5

4

3

2

1

Spindle Motor

1 - 469 2 - 946

3 - 1576 4 - 2259

5 - 3028

1

3

2

Ferm 3

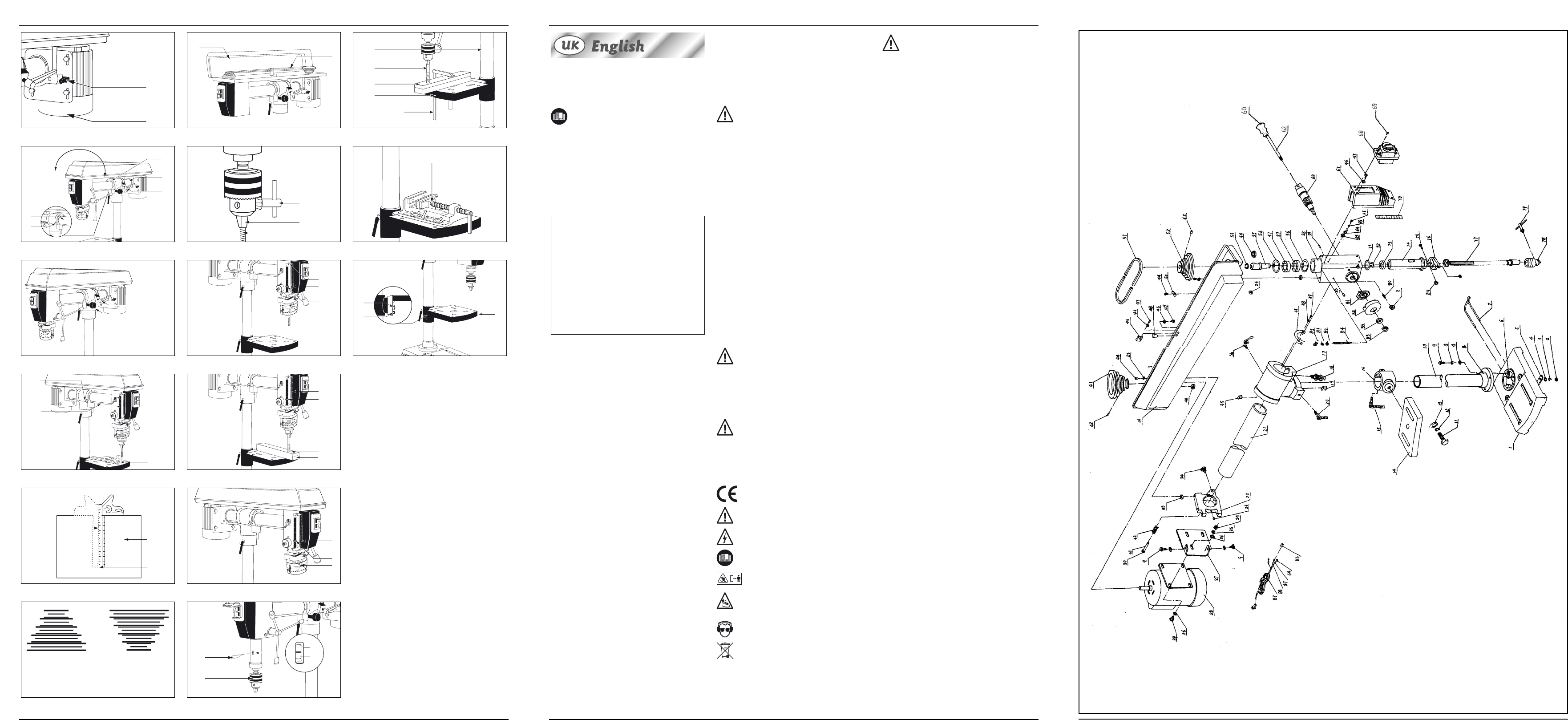

RADIAL ABLE DRILL

THE NUMBERS IN THE TEXT BELO

CORRESPOND TO THE ILLUSTRA

PAGE 2 + 3.

Caution! For your o

instructions for use befor

CONTENTS:

1. T

2. Safety instructions

3. Definitions

4. Directions for assembl

5. Directions for set up

6. W

7. Maintenance

1.

Product inf

Fig.

1 Motor

2 Mill-cut groo

3 Horizontal toothed rack

4 Rotation locking clamp

5Table support lock

6Table support

7 Conical locking scre

8 Conical scale

9Ver

10 Chuck

11 Spring cover

12 Return spring 0

13 On / off switch

14 Base

15 Stand

16 T

17 Drilling grips

18 Depth scale locking knob

19 Depth scale indicator

20 Protractor

21 Horizontal drill button

22 V

23 Belt tension locking button

24 Tilt locking clamp

25 Mill-cut groo

26 Drive belt guar

27 Spindle pulley block

28 Motor pulley block

General guidelines

• Inspect all parts after unpacking,

during transport.

the carrier should be immediately notified.

• Complaints made later will not be accepted.

• Inspect the delivery for completeness.

• Become familiar with the machine by reading the

operator’s guide thoroughl

• When fitting/replacing accessories,wear

reserve parts,

Spare parts are a

• When ordering,please specify our ar

and the machine type.

Remark:According to the applicable pr

la

damage caused to or by this appliance,

• Negligent operation.

• Failure to follo

guide.

• Repairs carried out by thir

workmen.

• The fitting of,

original Ferm spar

• Usage other than that for which the machine is

designed,

observing the electrical regulations and the VDE

pro

Westr

Before assembling and using the machine,

the complete text of the operator’s guide.

This operator's guide is designed to make it easier f

you to get to know y

make use of it’s man

The operator's guide includes important directions as

to how you can saf

the machine,

repair costs,reduce una

reliability and useful life of the machine.

Besides following the safety guidelines in this operator's

guide,

regulations applicable in y

machine.

Keep the operator's guide close to the machine

inside a plastic sleev

moisture.

by ever

ha

machine and who are a

should be allowed to operate the machine.

minimum age should be heeded.

Besides the safety guidelines in this operator's guide and

the specific regulations applicable in y

generally recognised technical rules f

woodw

Unpack the contents of the box and inspect them

closely

Should any par

connect the machine to the power supply until the

machine is complete and in order

Unpack the machine and parts carefully

them to the dra

To pr

been coated with a protectiv

removWD-40.

Topr

use petrol,naphtha,

volatile solutions for cleaning the machine

2.

In this operator's guide the following pictograms ar

used:

CE Conforms to the applicable Eur

standards

Danger of bodily injury or mater

Indicates electrical shoc

Read the instructions

Keep bystander

Immediately unplug the plug from the mains

electricity in the case that the cord gets damaged

and during maintenance

Wear eye and ear pr

Faulty and/or discarded electrical or electronic

apparatus have to be collected at the appr

recycling locations.

General safety instructions

Safety is a combination of common sense,

alertness and a good knowledge of the machine’s

operations.

Only inser

have read and understood the following dir

to avoid faults that could cause injury.

1. Read the entire operator's guide and become

familiar with its contents.

the tools and what the limitations and potential

hazards ar

2. Be absolutely certain that all safety precautions ar

operational,

3. Remove adjustment tools and spanners.Get

accustomed to checking,

machine,

ha

4. K

surfaces cause accidents.

5. Nev

Nev

places,

good lighting of the work ar

6. K

working with the machine,

distance from the w

7. Use locks if necessary

enter the work ar

8. Nev

The machine functions better and more safel

speed it was designed for

9. Use appropriate tools.Do not tr

the machine to operations it was not designed for

10. Use a regulation extension cable certain that it is in a

good state.

enough to carry the current dra

your w

dissipate the current,which leads to power loss and

overheating.

11. W

clothes,

accessories that could come in contact with moving

parts.

a hairnet.

12. W

possession.

thro

irreparable harm.

conform to the safety guidelines (not a normal pair

of glasses.) Normal optical glasses offer no

protection against objects fl

no safety glass in the lenses.If these lenses break,

can cause serious injury

13. W

14. W

or vice.

both hands free to operate the machine.

15. Remove the plug fr

performing maintenance,

accessories such as cutter

16. Reduce the risk of unintended activation of power

Verify that the pow

connect mains power

17. Only use recommended accessories.

accessories can be found in the operator's guide.

Poorl

personal injury

18. Nev

injury

come into contact with the cutting tools.

19. Inspect the machine for damaged parts.

make further use of the machine,

features as w

carefully inspected,as to whether they still function

without problem and can still perf

task.

and correct couplings;furthermore check for

breakages,correct assembly and an

conditions that could ha

machine’s functioning.

or damaged part must be repaired or r

workmanlik

20. Nev

turn off the power

has completely stopped moving.

21. Do not excessively lean,either forwards or

sidewa

and keep y

22. Perf

correct and saf

and clean.

and replacement of tools.

23. Nev

inflammable fluids or gases.

24. Do not work with the machine if y

influence of drugs,

limit your capability to r

Power|230

Frequency | 50

Unloaded speed | 469-3028/min

Number of speeds | 5

Power drawn | 350 W

Max. | 100 mm

Table rotation | 0˚ to 45˚ (L/R)

Table dimensions | 220 x 195 mm

Clearance | 115 x 435 mm

Dimensions base | 345 x 225 mm

Height | 725

Spindle distance | 100 - 340 mm

Chuck opening | 13 mm

Lpa (sound pressur | 65.5 dB(A)

Lwa (sound power le | 78.5 dB(A)

Vibration value | 0.853 m/s

2

4 Ferm

Ferm 53

EXPLODED VIEW