52 Ferm

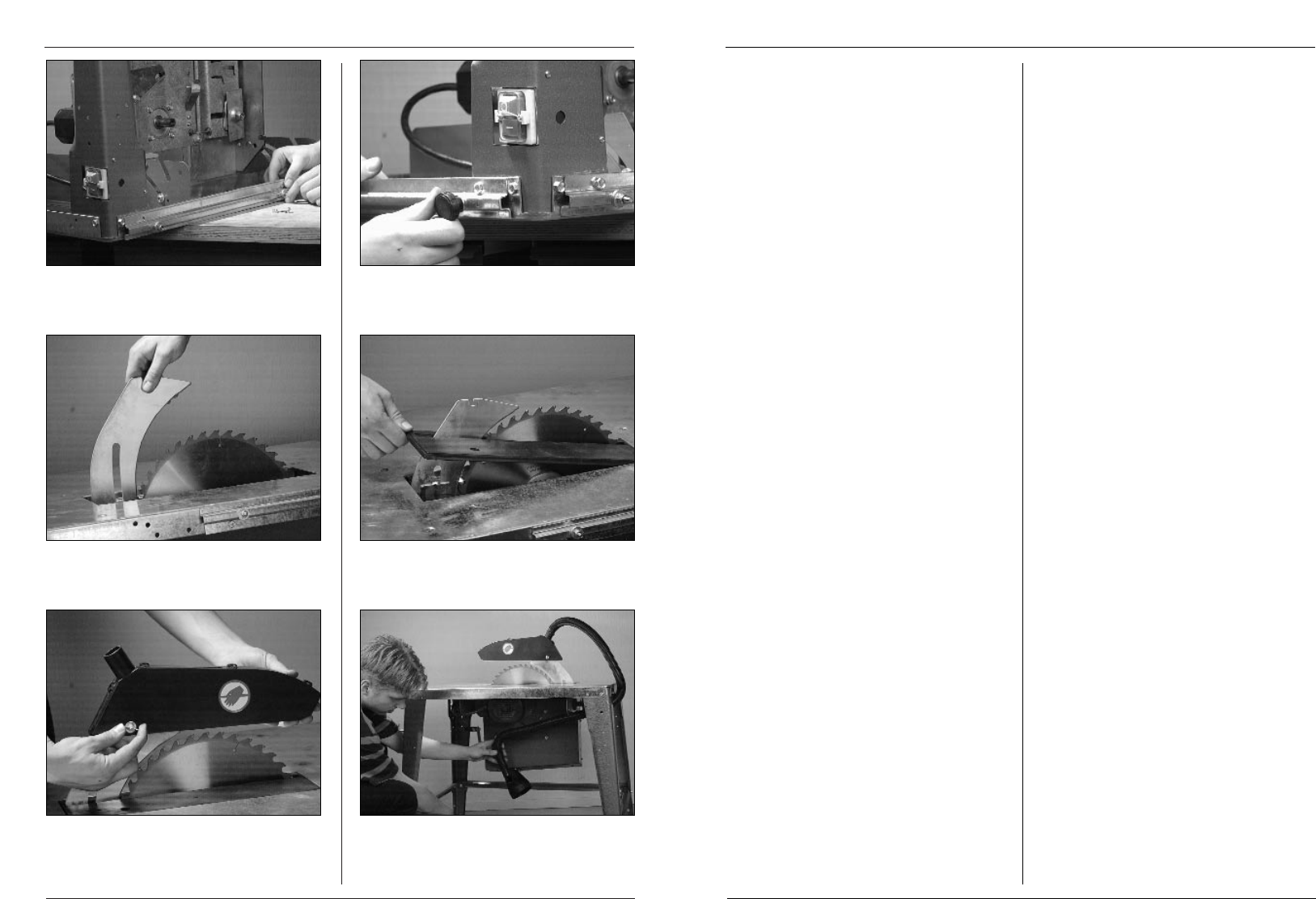

FIG. 7 FIG. 8

FIG. 9 FIG. 10

FIG. 11 FIG. 12

ASSEMBLY OF THE SAW BENCH

For assembly it is advised to put the machine on a suitable

working surface, for example a bench top.

(The numbers mentioned in the text correspond with

the numbers of the exploded view)

Photograph 1

First assemble the leg (nr. 15) with the slot for the mains

switch. Fix this leg with two hex bolts M6 x 16, a washer

and a self locking nut.

ATTENTION: Fix the bolts only in the most inner holes,

and do not tighten the bolts firmly yet. Then continue with

the other legs in similar way, the numbers of the legs must

correspond with the numbers on the table.

Photograph 2

Assemble the switch using the 2 self tapping screws.

Photograph 3

Fix the cable with the two cable ties to the engine support

plate (Nr. 9). Please note that there should be enough

slack in the cable, because this part can be put under be-

vel angle and is in height adjustable.

Photograph 4

Assemble the shaft with wheels, first loosen the self-loc-

king nuts and the rubber rings.

Place the shaft with wheel between leg 15 and 17. Fasten

the self-locking nuts and rubber rings again with the aid of

the supplied locking bar.

Photograph 5

Assemble the two long (Nr. 19) and the two short supports

(Nr. 20) using hex bolts M6 x 16, washers and self locking

nuts. However do no fix the bolts tightly yet.

Photograph 6

Assemble the dust extraction adapter (Nr. 26) using 4 hex

bolts M4 x 10.

Photograph 7

Assemble the guide (Nr. 22) for the cross cutting fence on

the left side of the table. Use 2 hex bolts M6 x 16 with self

locking nut and washer to fix it together with the table legs.

Assemble the support for the dust extraction hose on the

right rear corner of the table, together with the table leg.

Photograph 8

Assemble the guide (Nr. 22) for the rip fence. Use 2 hex

bolts M6 x 16 with self locking nut ,washer and rubber

washer to fix it together with the table legs.

NOTE: First put the rubber washer on the bolt, then insert

the bolt through the hole of the table and guide. Then in-

sert two coach bolts into the designated slots and add a

washer and small star grip (Nr. 24).

Now fasten all the bolts of the frame, starting with the front

legs. Turn the machine up side down on its legs.

Photograph 9

Remove the table insert to loosen the 6 screws, loosen

the bolt for the riving knife and assemble the riving knife

(Nr. 31). Ensure a space of between 3 and 8 mm between

the riving knife and the sawblade at any point. Fasten the

bolt for the riving knife.

Photograph 10

Re-insert the table insert (Nr. 32) and fix it with the 6

screws.

Photograph 11

Turn the sawblade in the highest position, loosen the

cross-head bolt on the top guard. Assemble the top guard

(Nr. 33) on the riving knife and fasten the cross-head bolt

again.

Photograph 12

Assemble the dust collection hose, and fix it into the sup-

port at the rear right corner of the table.

Photograph 13

Slide the crosscut / mitre scale (Nr. 35) into the front rail.

Photograph 14

Place two hex bolts (Nr. 43) in the holes of the mitre scale

and add the two wing nuts loosely to it. Then slide the alu-

minium rip fence (Nr. 37) over the head of the bolts.

Put the scale label on the machine.

Slide the aluminium guide against the saw blade and stick

the scale label in the notch of the table, with the zero bene-

ath the aluminium guide.

CONNECTION INSTRUCTIONS

The sawing machine must be connected to 230V (220V)

mains voltage by means of the female plug supplied. The

sawing machine must be placed firmly on a level floor.

PUTTING INTO OPERATION

By pressing the GREEN button of the safety switch (part

nr 13) the sawing machine is switched on.

By pressing the RED button of the safety switch the sa-

wing machine is switched off.

In case of an unexpected mains voltage failure or in case

the mains plug is pulled from the mains (the wall socket),

the safety switch will immediately switch off. If the mains

voltage should now suddenly come back again, the sa-

wing machine will not switch on. The sawing machine will

only be switched on again after pressing the GREEN but-

ton.

INSTALLATION

1. ADJUSTING THE SAW HEIGHT

By turning the large hand wheel on the engine suspension

(part nr 6/53) the saw blade height can be adjusted be-

tween 0 and 88 mm (with 45° 62 mm). By turning the hand

wheel to the right, the saw blade is adjusted

higher, and by turning it to the left the saw blade is adjus-

ted lower. By one complete turn of the hand wheel the saw

blade height is altered by 1.2 mm. The saw blade must

protrude 10 mm above the workpiece during sawing. In

this way the downward teeth of the saw blade will press

the workpiece down on the bench top.

2. ADJUSTING THE SAW ANGLE

By loosening the small handle (twice) on the engine sus-

pension the saw blade can be tilted between 0° and 45°.

The adjusted saw angle can be read by means of the de-

gree division on the engine suspension.

Ferm 5