If the frame is used, it must be fixed on the floor with

four screws and the machine must be fixed on the fra-

me with four screws. Check the screws before swit-

ching the machine on.

ASSEMBLY AND SETTING-UP OF THE FENCE

- Raise the handle upwards so that the claw of the guide

is open enough in order to place the fence on the ben-

ch top.

- Now lay the fence on the bench and install the back

part (with the claw) and then place the front part over

the rail. With the handle at the front of the fence you

can adjust the clamping stress of the fence.

Lock the fence by pushing the handle downwards. If

the handle cannot be pushed through far enough, the

clamping stress is too high and you must turn the

handle a few turns looser. If the handle can be pushed

through far enough but the fence is not fastened or

loosens by vibration, the clamping stress is too low

and you must turn the handle a few turns tighter.

ASSEMBLY OF THE RIVING KNIFE AND OF THE TOP

GUARD

- Turn the saw blade completely upwards.

-Remove the bench inlay.

- Assemble the riving knife on the set-up for this purpo-

se and use hereby the Allen screws and the filling

rings. Ensure that the riving knife falls properly into the

opening (= groove).

- Now put the inlay back in the bench and fasten it.

- Now assembly the top guard onto the riving knife and

use hereby the profiled nut and self-locking nut.

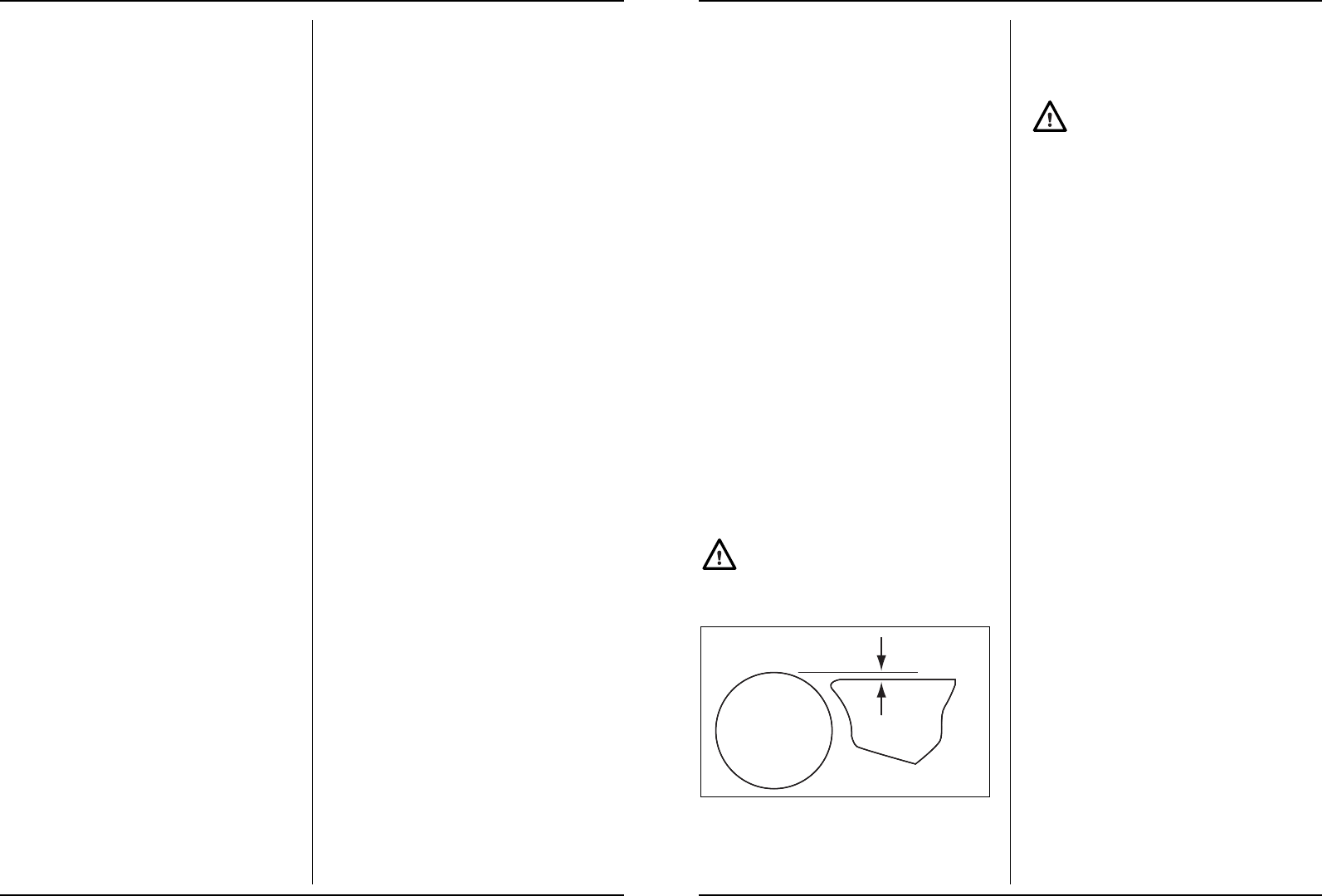

- The riving knife should be adjusted that the radial dis-

tance between the blade and the riving knife is not

more than 8 mm. and not less then 3 mm. at any point.

Now lay a lath against the saw blade and the

riving knife and check whether it falls properly

into the extension of the saw blade. If this is not the case:

Loosen the fastening bolts and place or remove the filling

rings.

Fig. D.

- Above the saw table the radial distance between the

riving knife and the toothed rim of the saw blade shall

not at any point exceed 5 mm at the depth of cut set.

- The tip of the riving knife shall not be lower than 5 mm

from the tooth peak, as shown.

ASSEMBLY OF THE SAW BLADE

First remove the plug from the mains before the

saw blade is assembled or replaced.

- Remove the inlay from the bench. Use a screwdriver

for this purpose.

- Turn the saw axle completely upwards. Remove the

nut and the outside flange from the saw axle.

- Now slide the saw blade over the saw axle and now

put the outside flange and the nut back. Tighten the

nut by hand.

- Now use the 2 keys: one for the flange and one for the

nut and now clamp it.

- Now put the inlay back in the bench and fasten it.

ADJUSTING THE Cross cut GUIDE

- In order to adjust the cross cut fence the tension but-

ton must be loosened by one turn. In this way the sca-

le part can move freely.

- Place a protractor (90°) against the contact side on

the one hand and the direction of sliding on the other

hand.

- Now turn the scale part in such a way that both sides of

the protractor connect correctly.

- Now turn the tension button back until it is fastened.

USE OF THE BEVEL SET-UP

By turning the height adjustment/mitre adjustment handle

at the side of the machine you can adjust the saw blade to

a maximum of 45°.

To adjust the saw blade:

- loosen the mitre locking handle.

- Press the mitre adjustment/height adjustment handle

and at the same time turn it around to place the saw

blade in the angle required.

- Tighten the mitre locking handle again.

USE OF TABLE EXTENSIONS

By using the table extensions the table’s dimensions can

be extended to 660x865 mm maximum.

To mount a table extension:

- remove the bolts at the side of the table.

- position the table extension and hold it.

- put the bolts back and tighten these.

5 mm max.