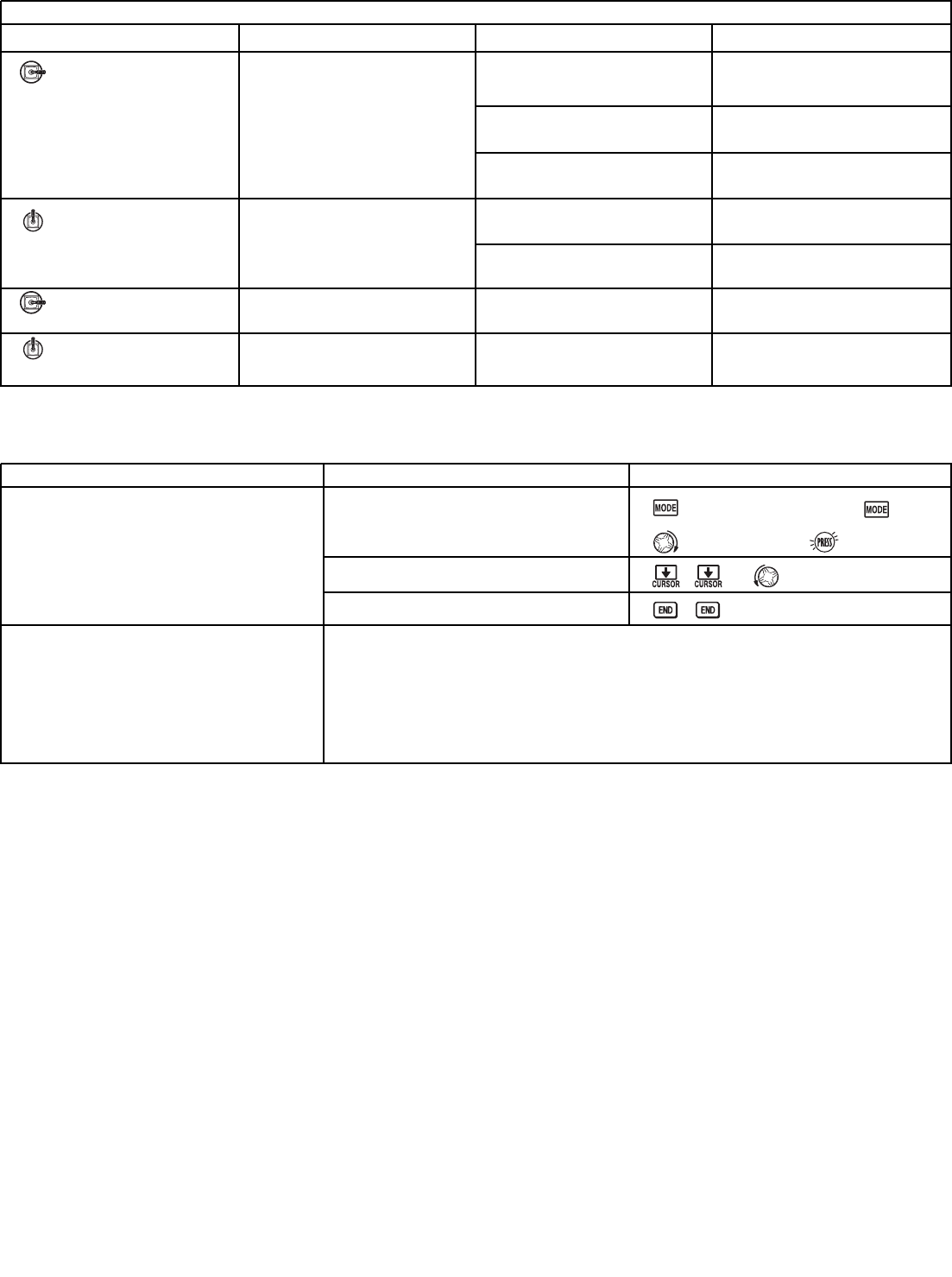

CHECKING FOR PROPER MOTION ON AN HR3 SWASHPLATE

GOAL of EXAMPLE: STEPS: INPUTS:

64

Adjust the travel of the collective pitch

from +50% to -23%, reversing the

travel of all 3 servos and decreasing

their travel in collective pitch only,on

an HR3 MODEL TYPE.

Where next?

Open SWASH AFR function.

Adjust PIT travel to -23 .

Close the menu.

for 1 second.

(If ADVANCE, again.)

to SWASH

to -23%.

Confirm the swashplate is level at 0 travel. Adjust arms if needed.

Apply full collective and check that the swashplate remained level. If not, adjust

servo's travels as needed to correct. END POINT:seep. 32.

Set up the normal condition: (TH-CV/NOR, PI-CV/NOR, REVO./NOR): see p. 65.

Set up D/R,EXP: see p. 34.

HR3 Swash Type

AILERON STICK.

E

LEVATOR STICK.

R

UDDER STICK.

THROTTLE STICK.

PROPER MOTION

Swashplate tilts right.

Front of swash plate moves

down; back of swashplate

moves up.

The leading edges of tail

blades rotate left.

Entire Swashplate lifts.

WRONG MOTION

Swashplate tilts left.

Back of Swashplate moves up.

Back of Swashplate moves

down.

Swashplate moves the

opposite.

Entire swashplate moves up.

Blades rotated right.

Swashplate lowers.

HOW TO FIX

Reverse AIL setting in

SWASH to -50%.

Ch6 servo moves

incorrectly; REVERSE.

Ch1 servo moves

incorrectly; REVERSE.

Reverse ELE setting in SWASH.

(ex: +50 to -50 )

Ch2 servo moves

incorrectly; REVERSE.

REVERSE the rudder servo.

Reverse PIT setting in SWASH.