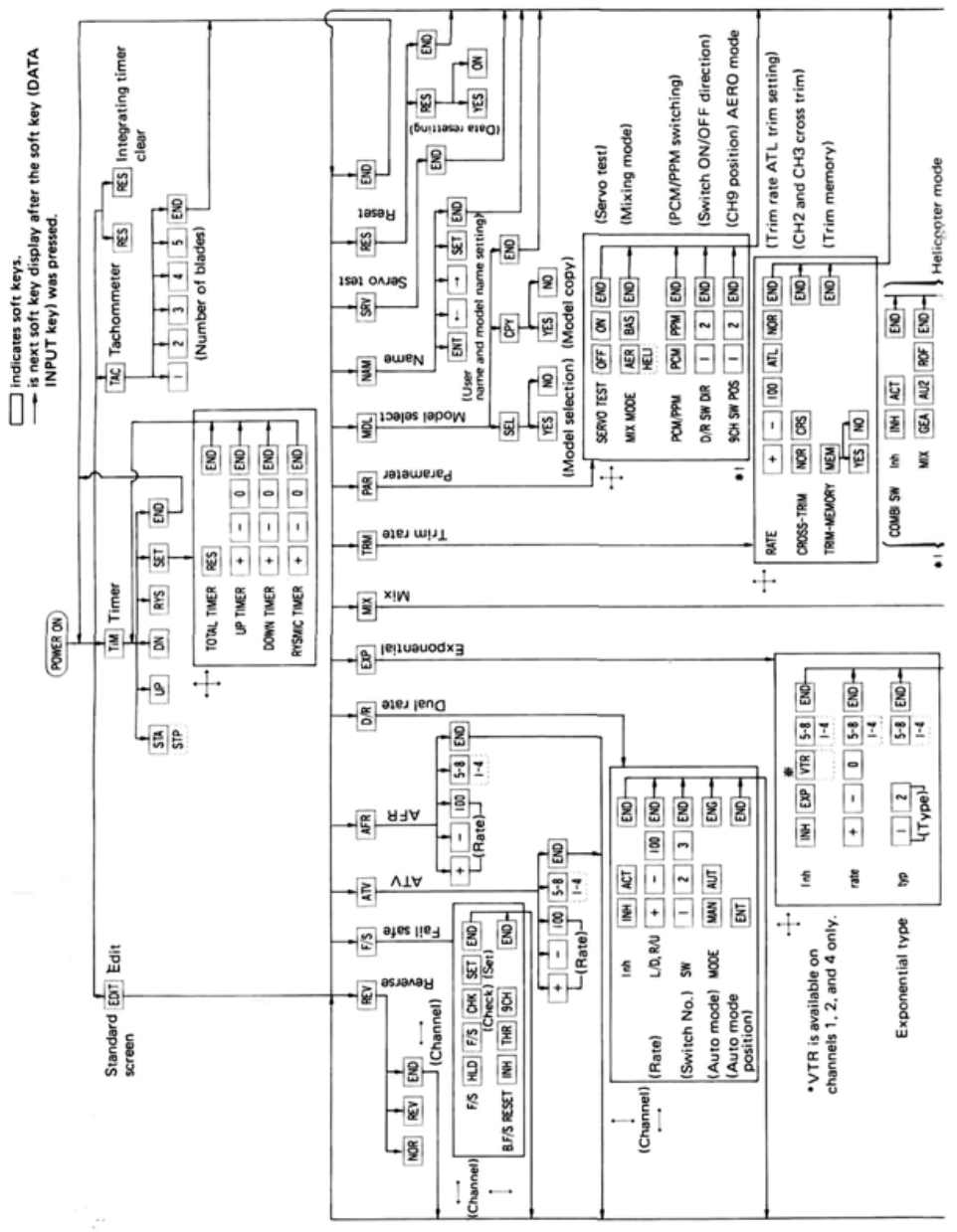

•FEATURES

The PCM1024A was specially-developed to meet the needs of the serious and demanding

R/C hobbyist. Numerous features make this system adaptable to a wide variety of complex

radio control stunt and scale aircraft. This is the most advanced system available for FAI

Precision Acrobatic (F3A) competition. The built-in microprocessor utilizing PCM (Pulse

Code Modulation) makes this set very versatile and extremely noise and deadpoint resistant.

Please read this manual carefully before using your set.

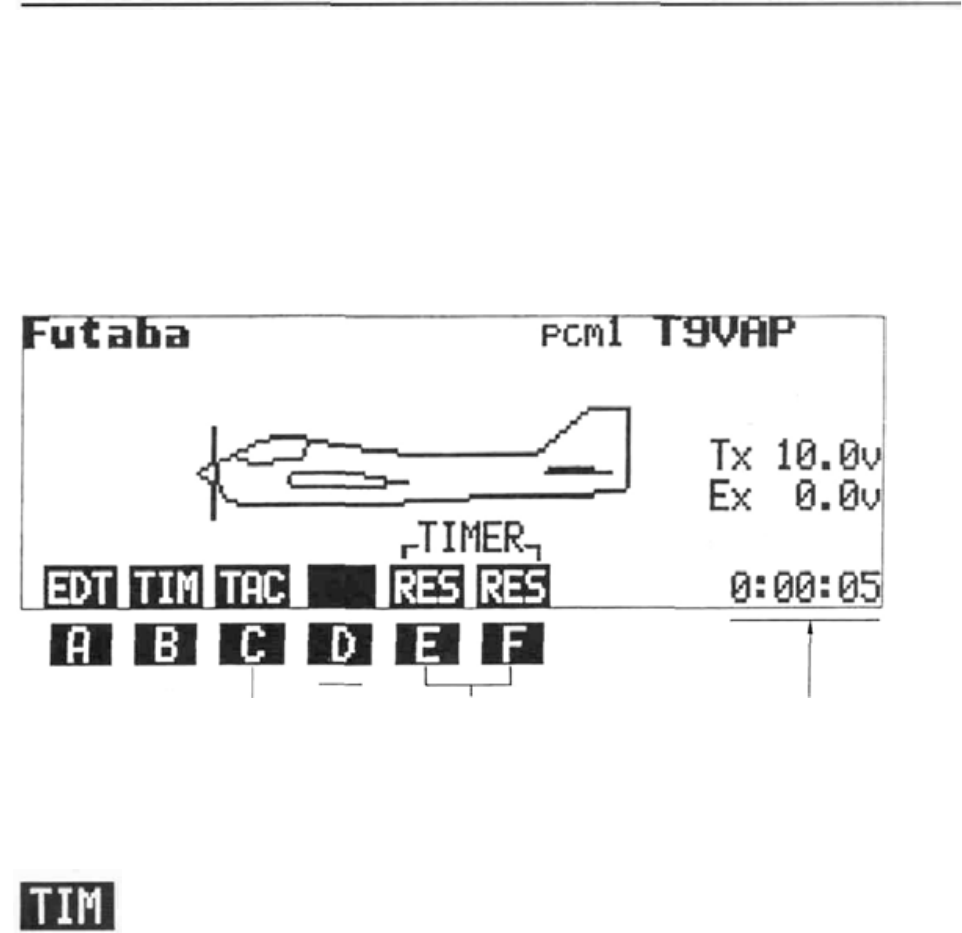

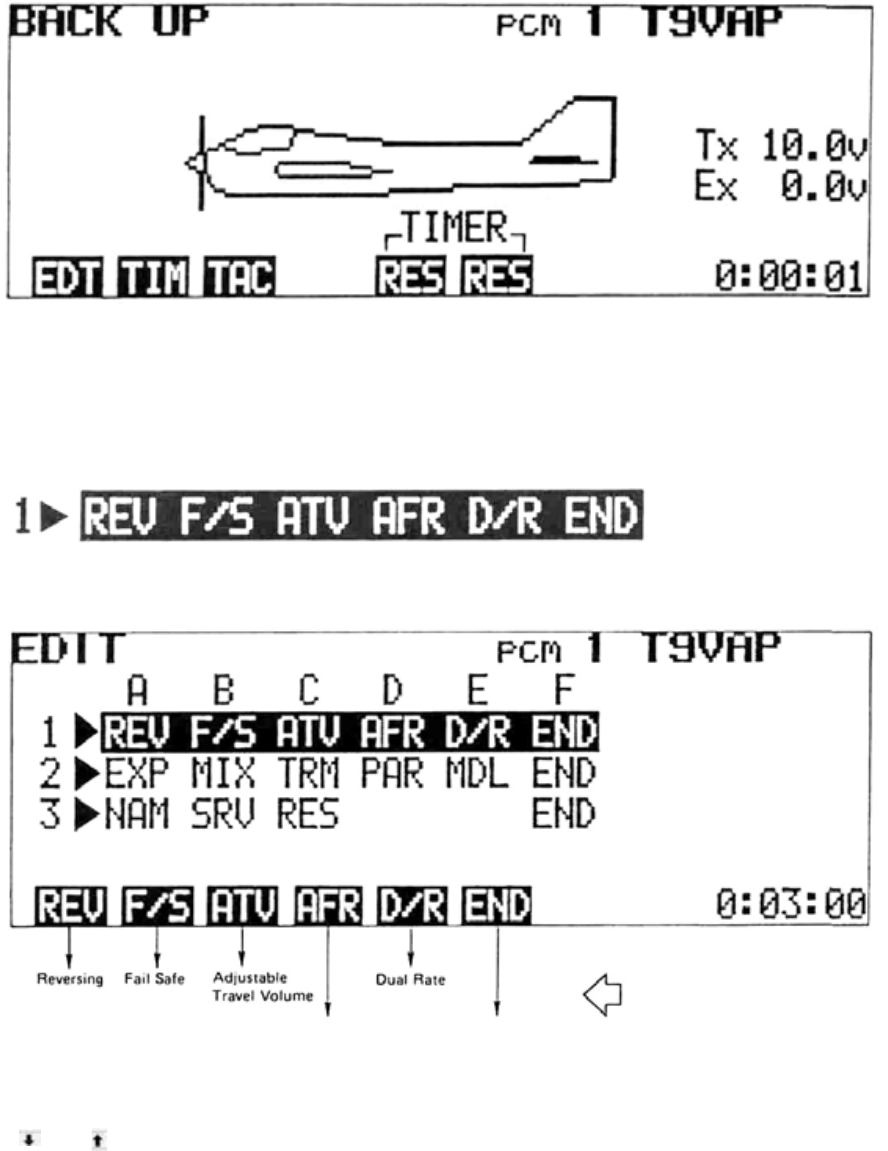

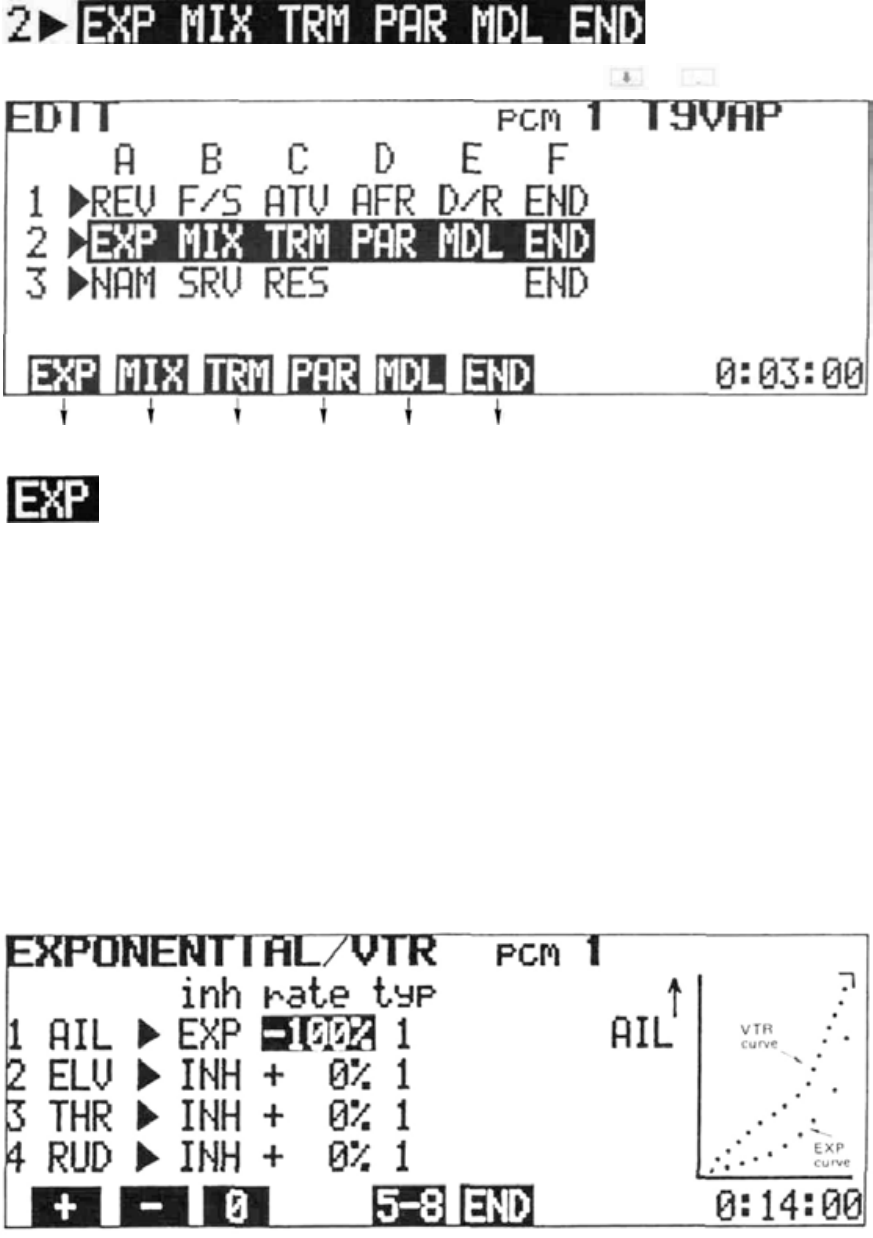

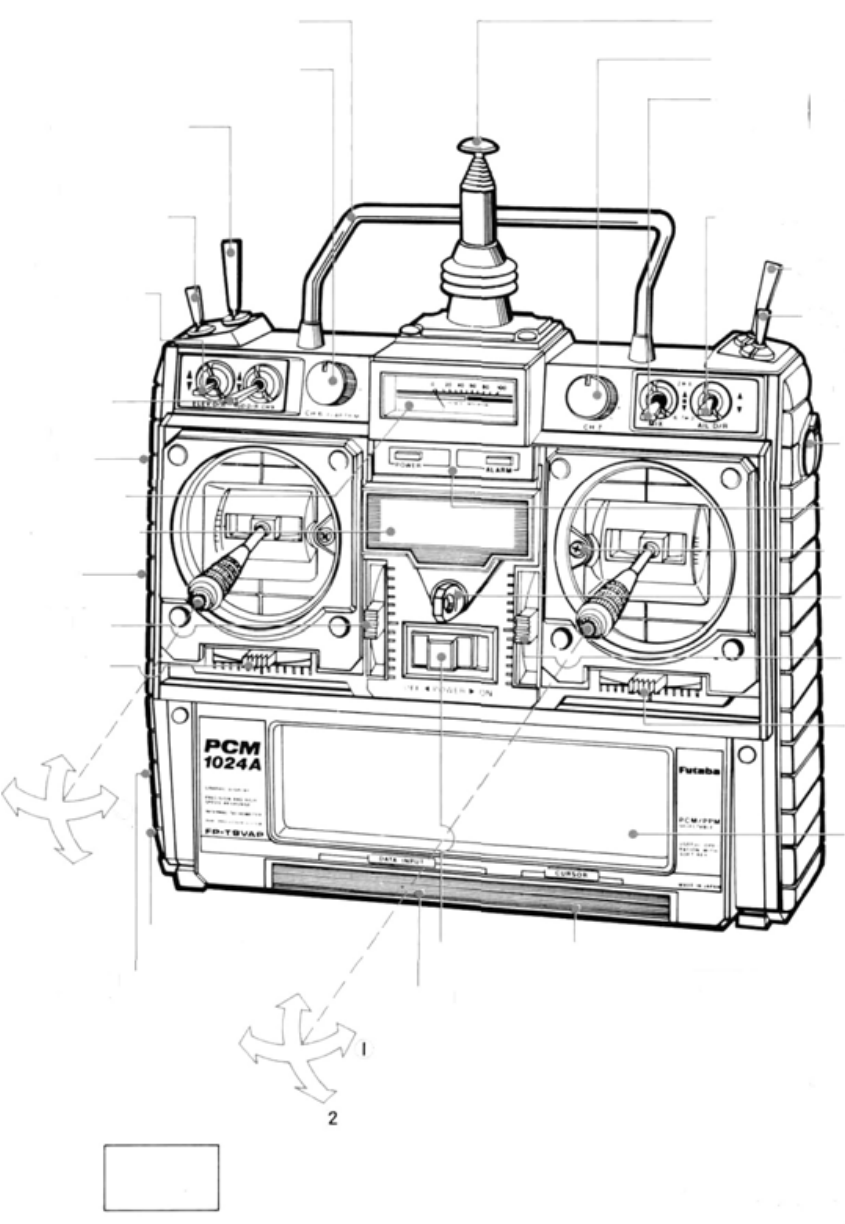

TRANSMITTER FP-T9VAP

• Programming data is displayed pictorially and

graphically on a large, easy-to-read LCD

(Liquid Crystal Display) panel. Programming

and Cursor keys allow convenient adjustment

of aircraft functions.

•"1024"

Channel Resolution: New 1024 PCM

encoder format provides unexcelled servo reso-

lution and response time.

•

RF

module uses a narrow

band

modulation

circuit and PCM transmission.

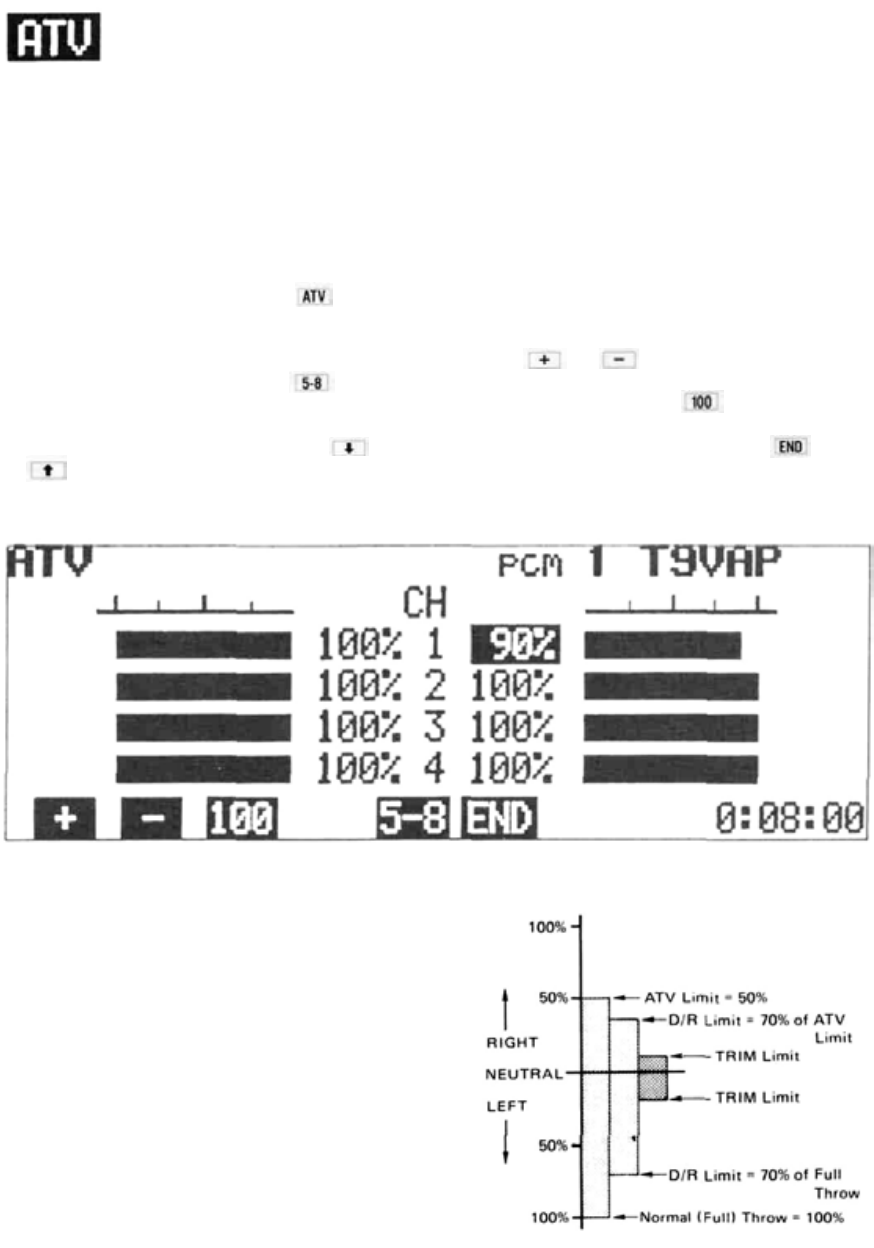

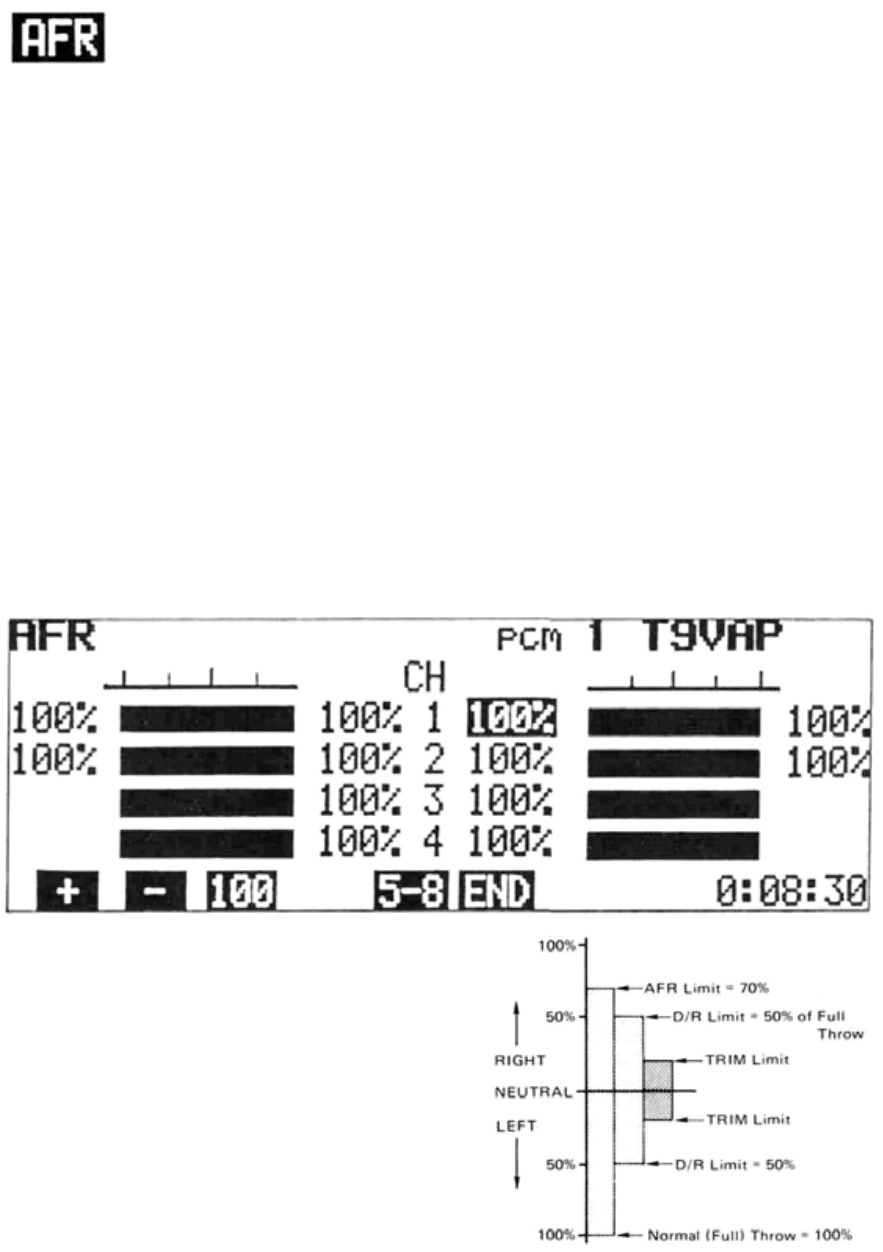

• Precise control is made possible by.. three dif-

ferent endpoint adjustment functions: Adjust-

able Travel Volume (ATV), Adjustable Func-

tion Rate (AFR), and Adjustable Trim Rate.

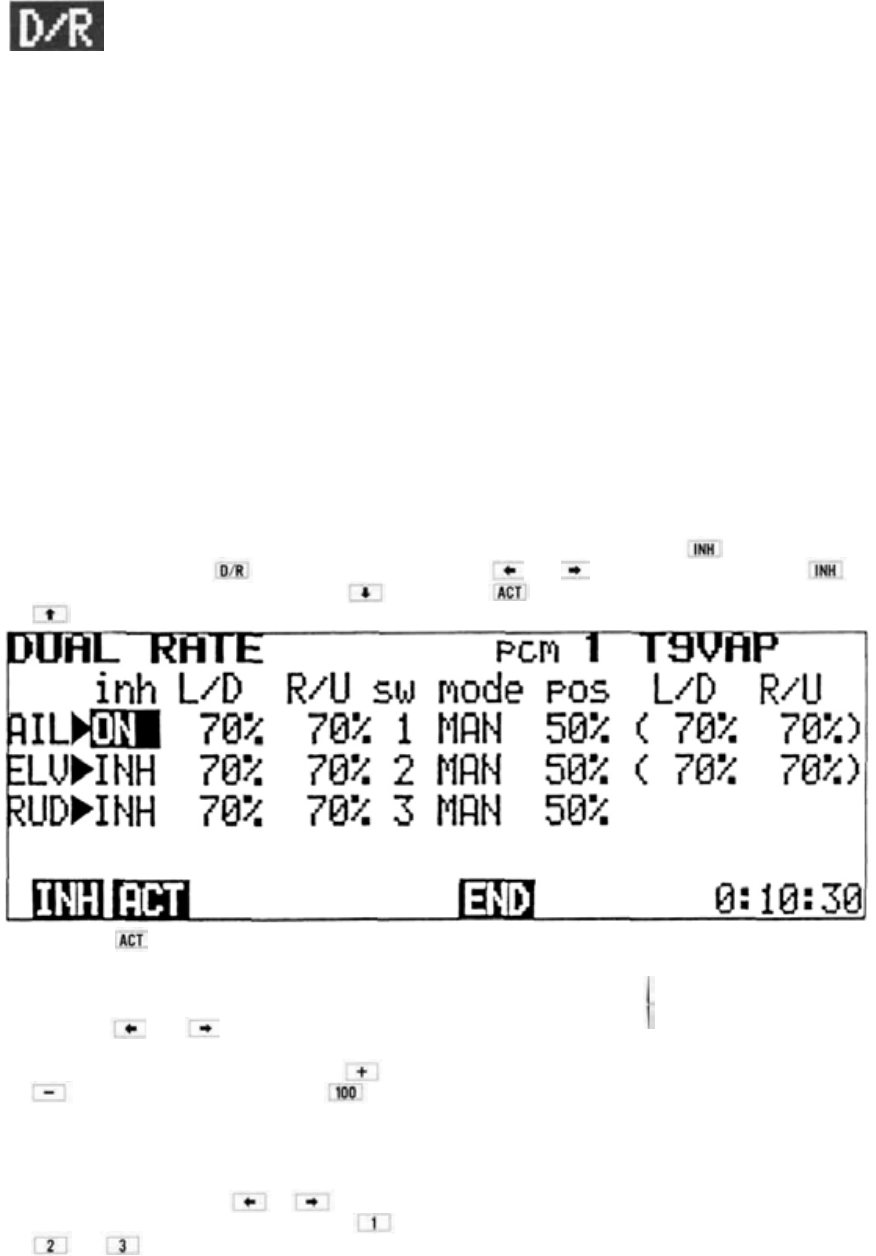

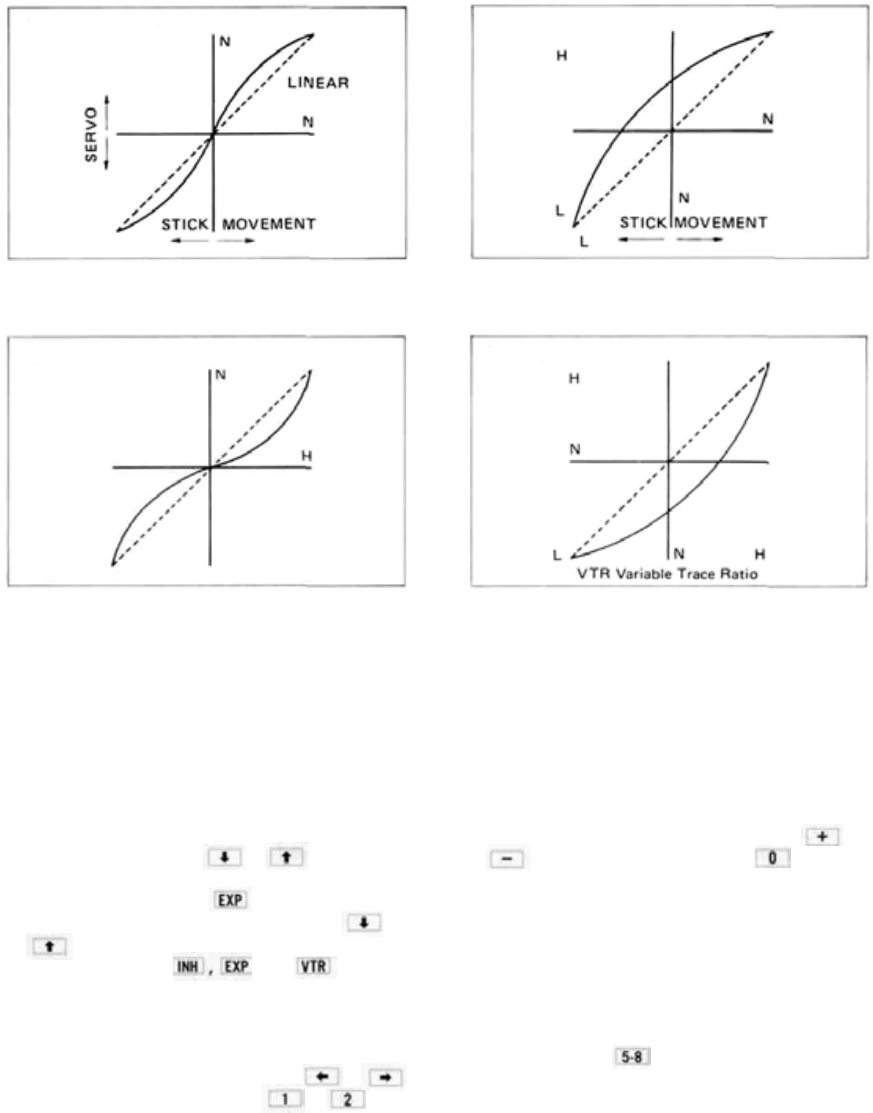

• Dual Rates, Exponential, and Variable

Trace

Rate (VTR) functions provide unlimited flexi-

bility

in

"fine

tuning"

aircraft

control

response.

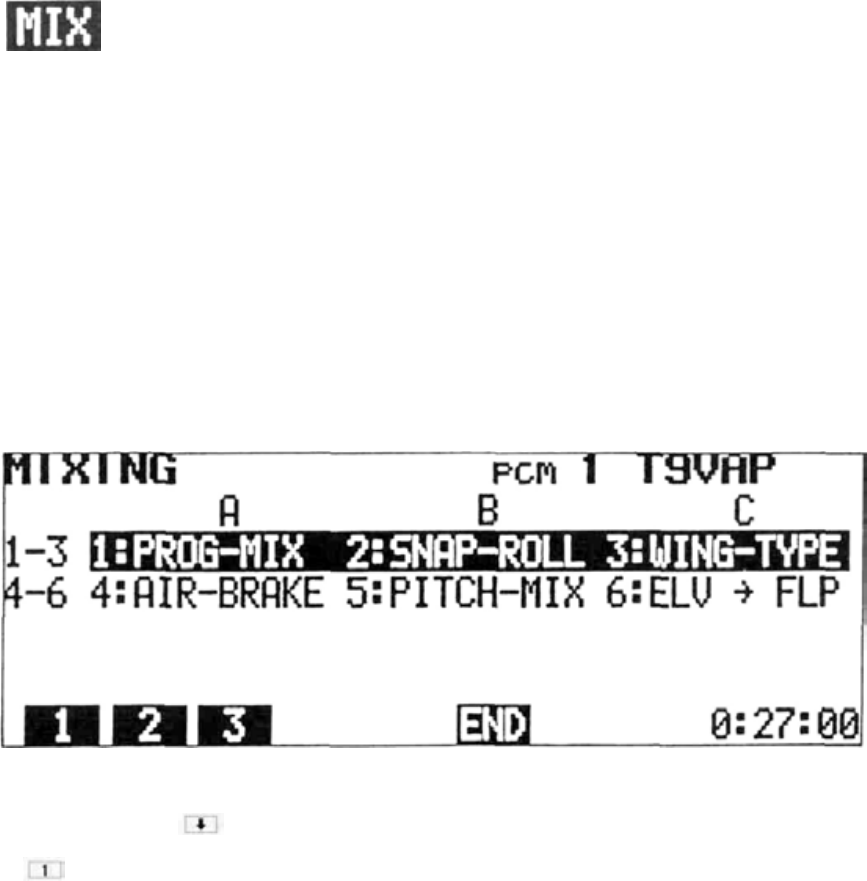

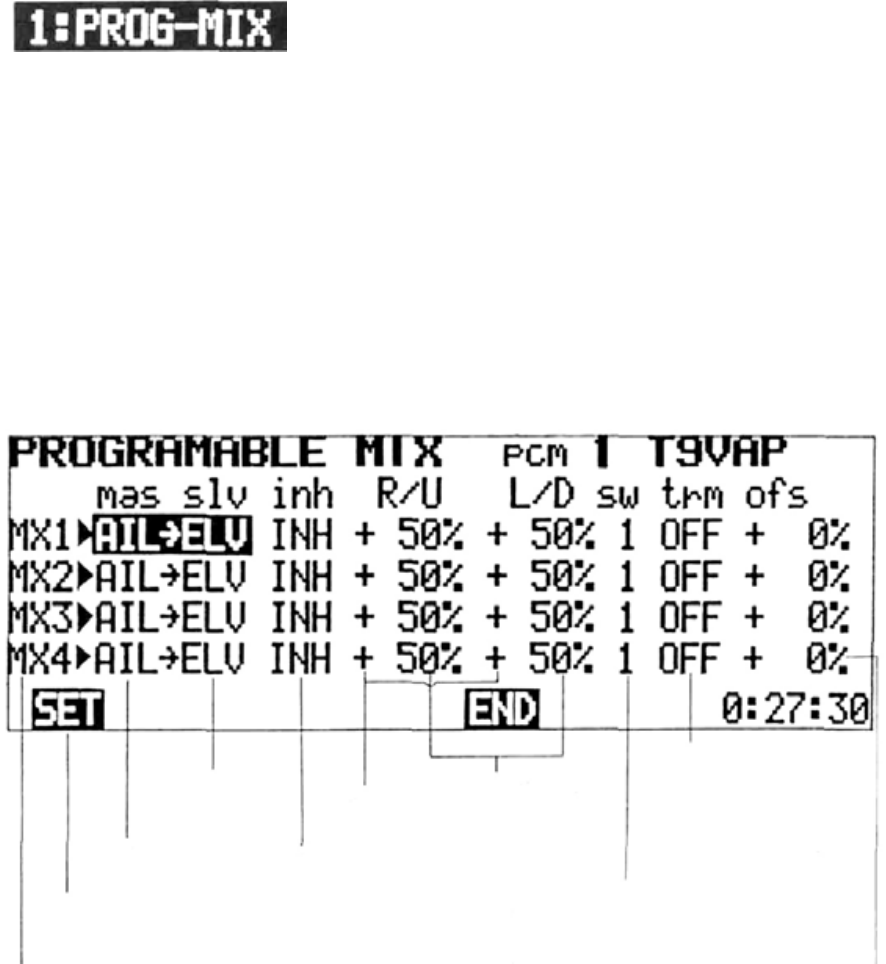

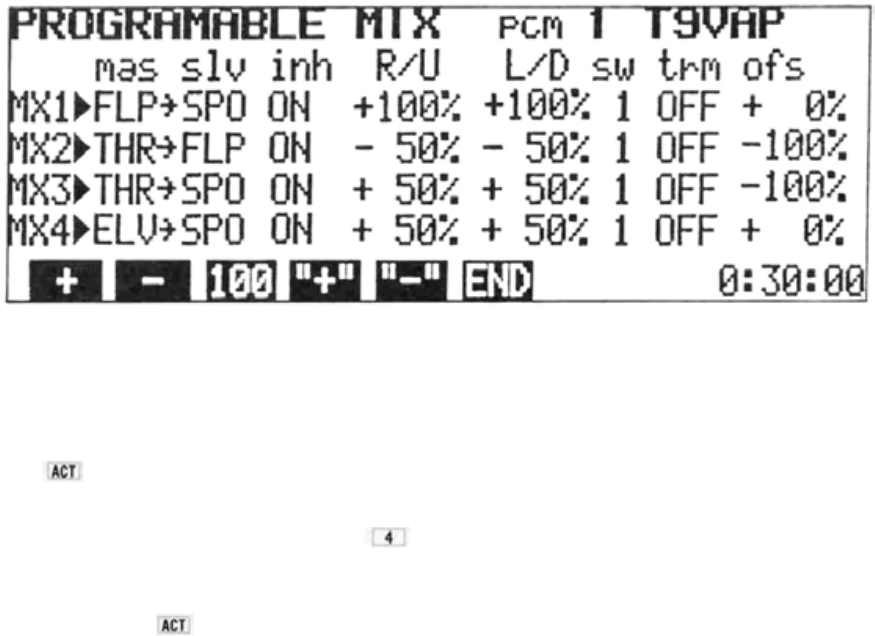

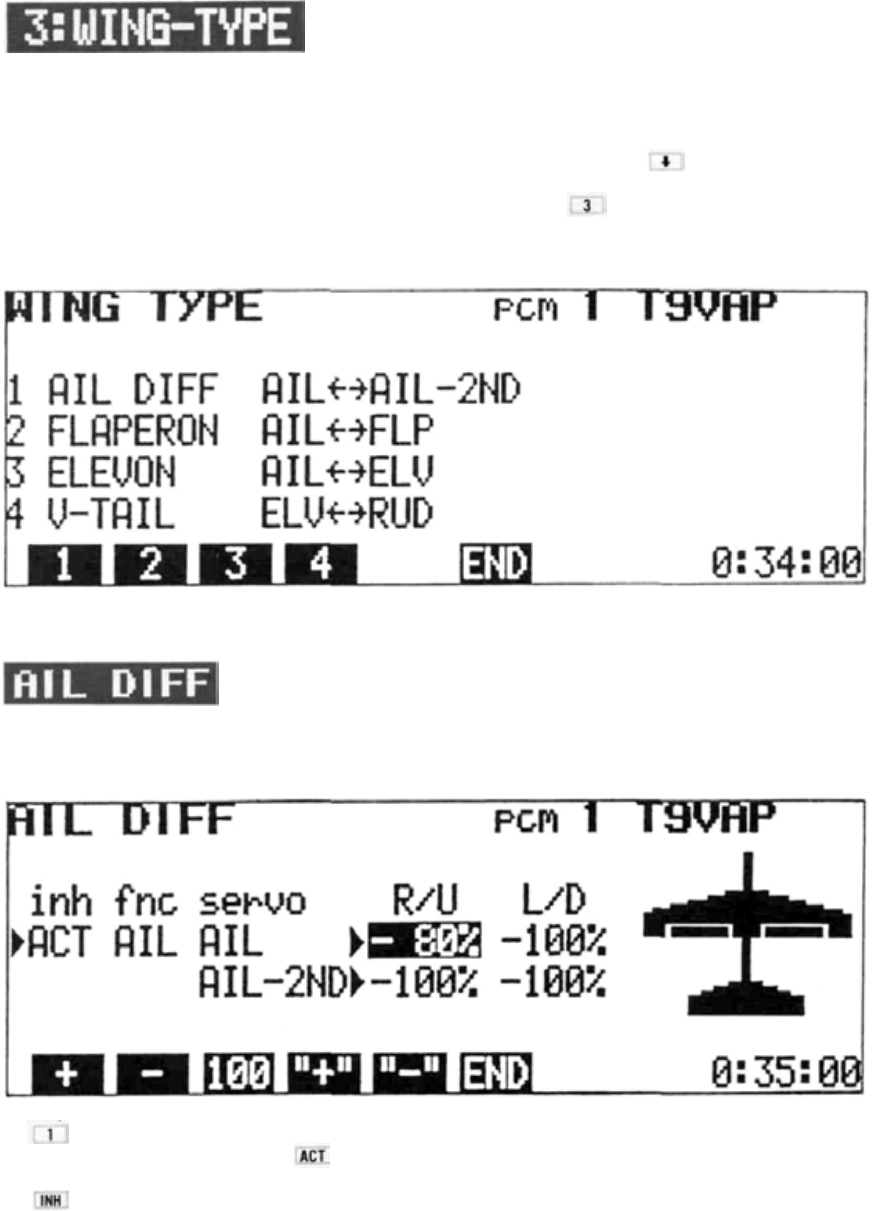

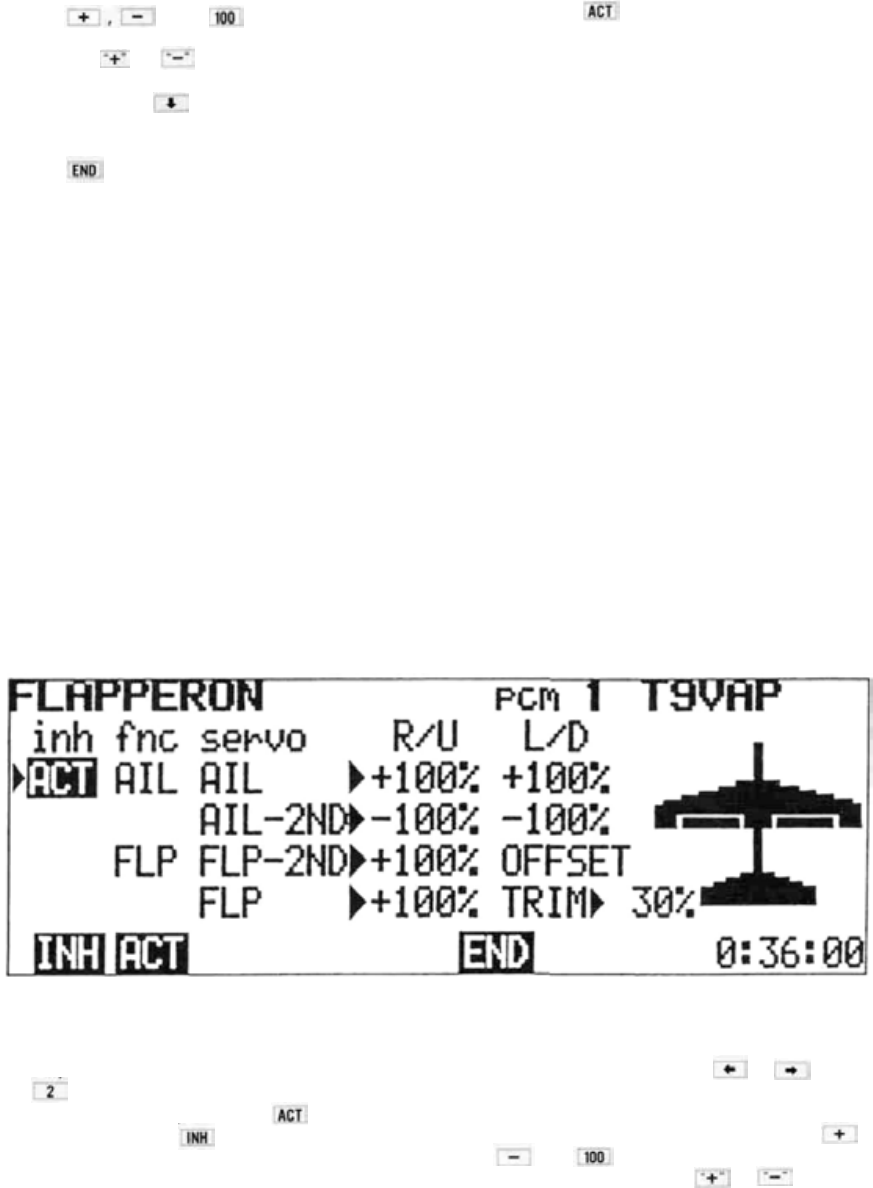

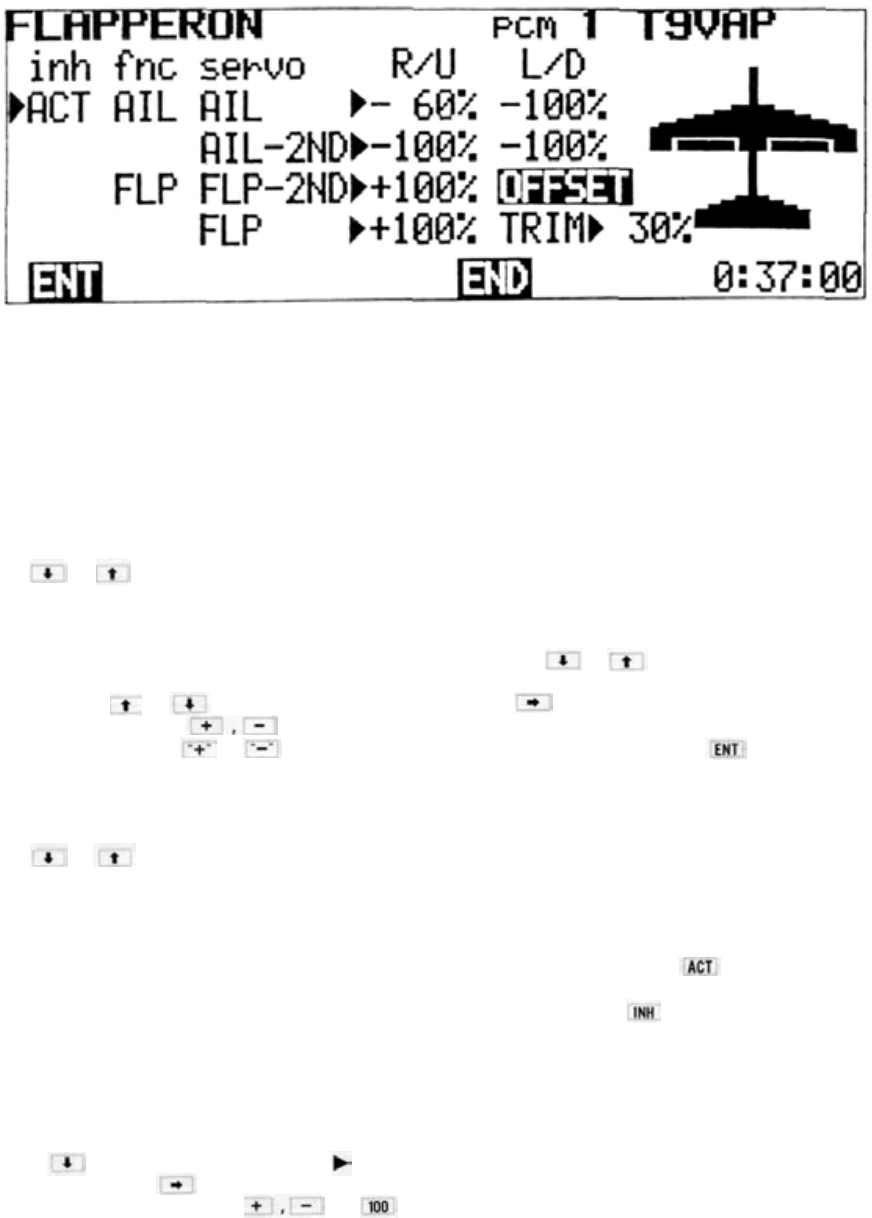

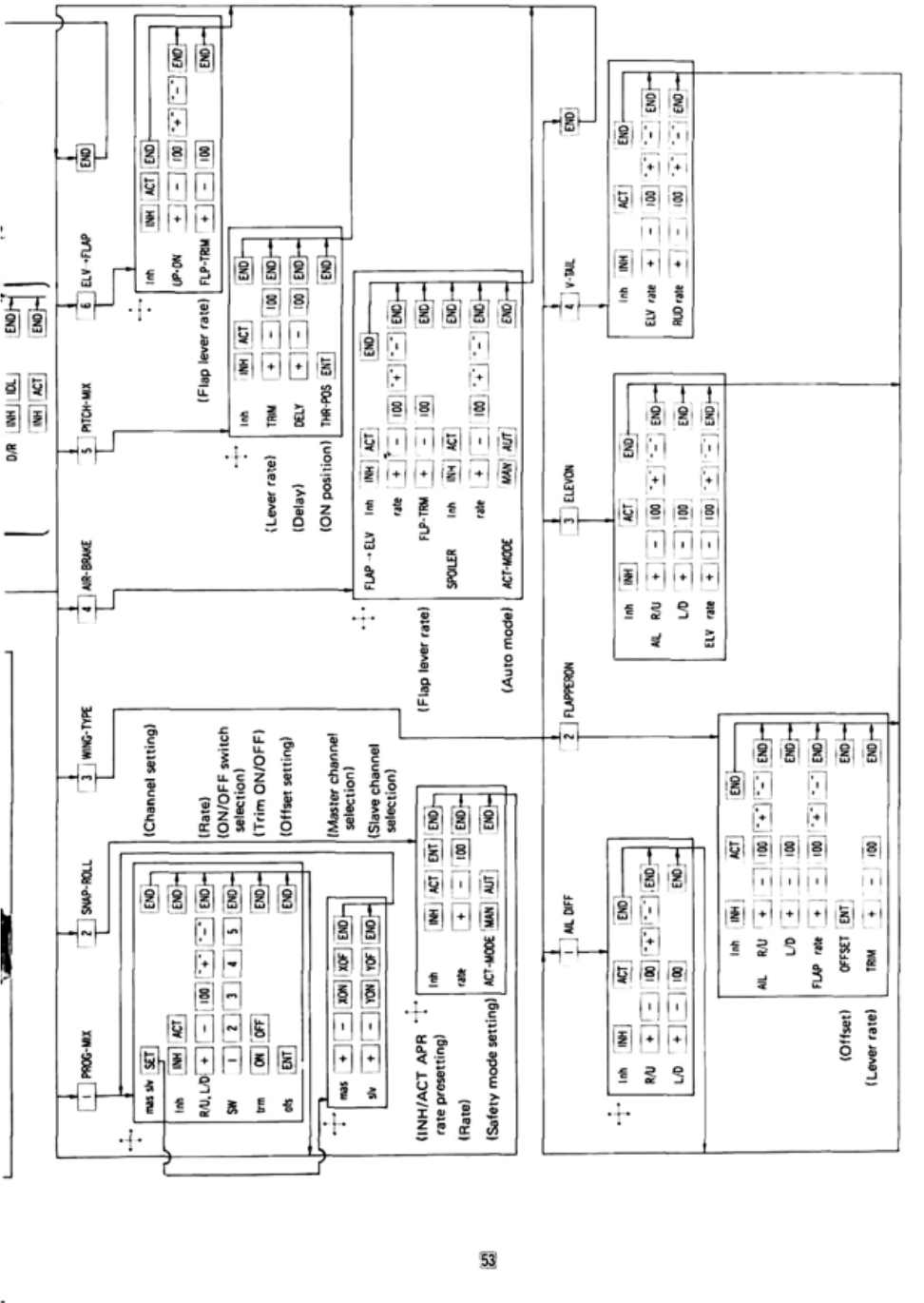

• Numerous special control mixing functions

have been refined for FAI R/C aerobatics

(F3A). Four programmable mixing circuits

provide tremendous versatility in adapting the

system to diverse and specialized applications.

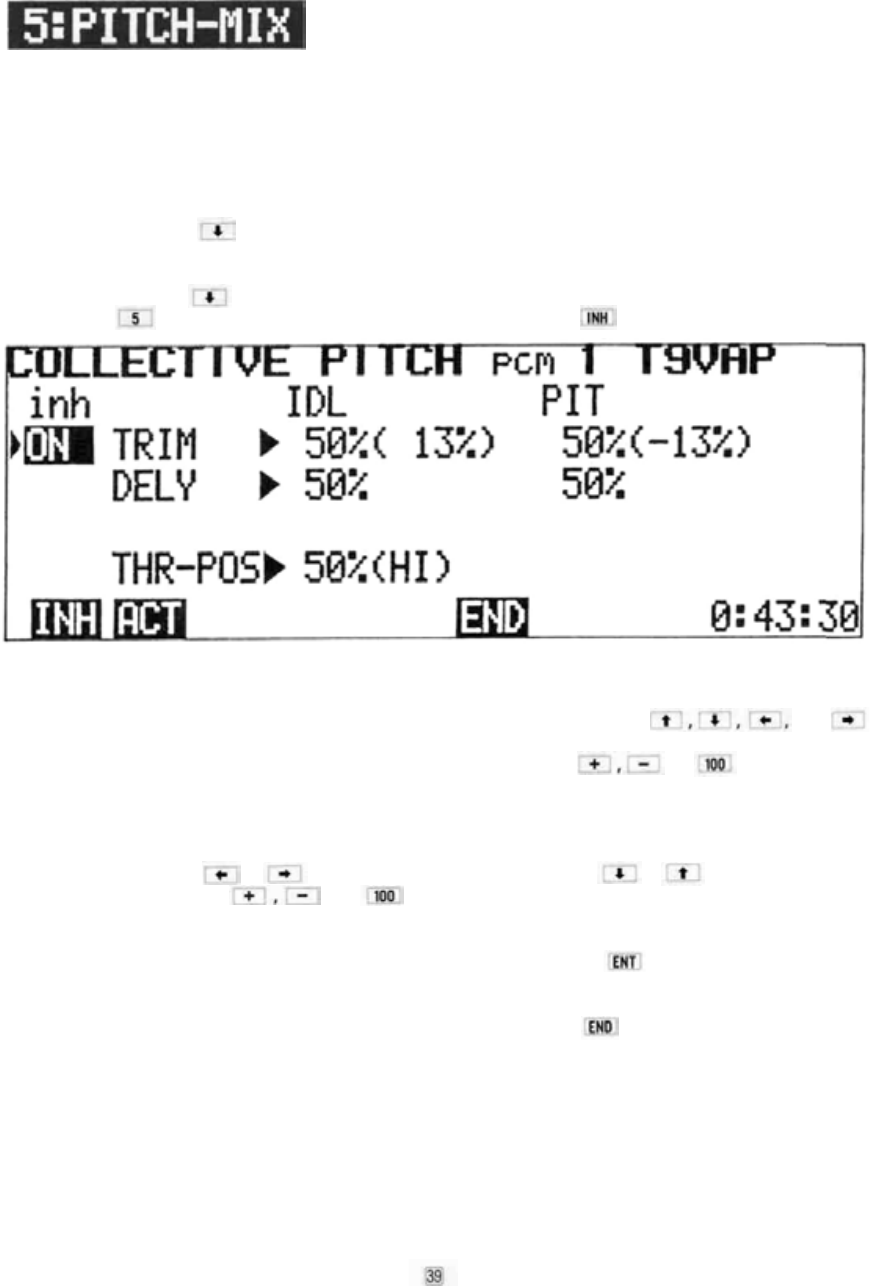

•Throttle -> pitch control mixing circuit is

designed for use with variable-pitch propellers

to maximize engine performance and reduce

noise.

• Idle-Up lever: The engine idle speed can be

independently adjusted during throttle ->

>

pitch

control mixing.

•Pitch

control

lever:

High

pitch

position

on

variable-pitch propellers is trimmable with the

lever.

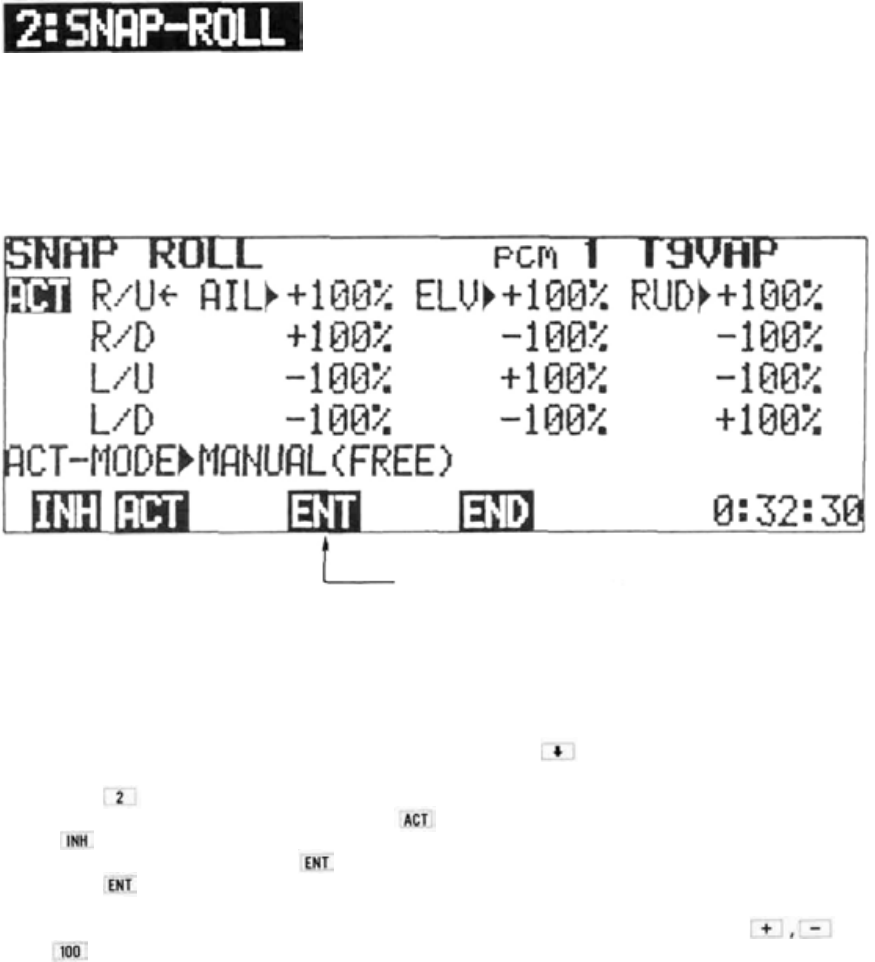

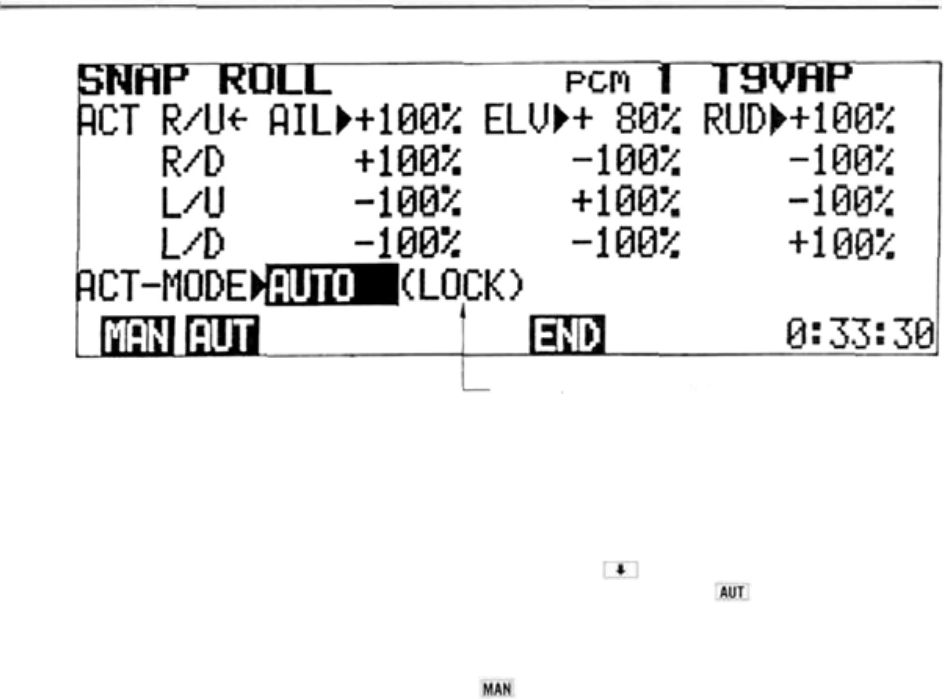

•Snap roll program allows four different pro-

grammable snap rolls to be performed at the

touch of a button.

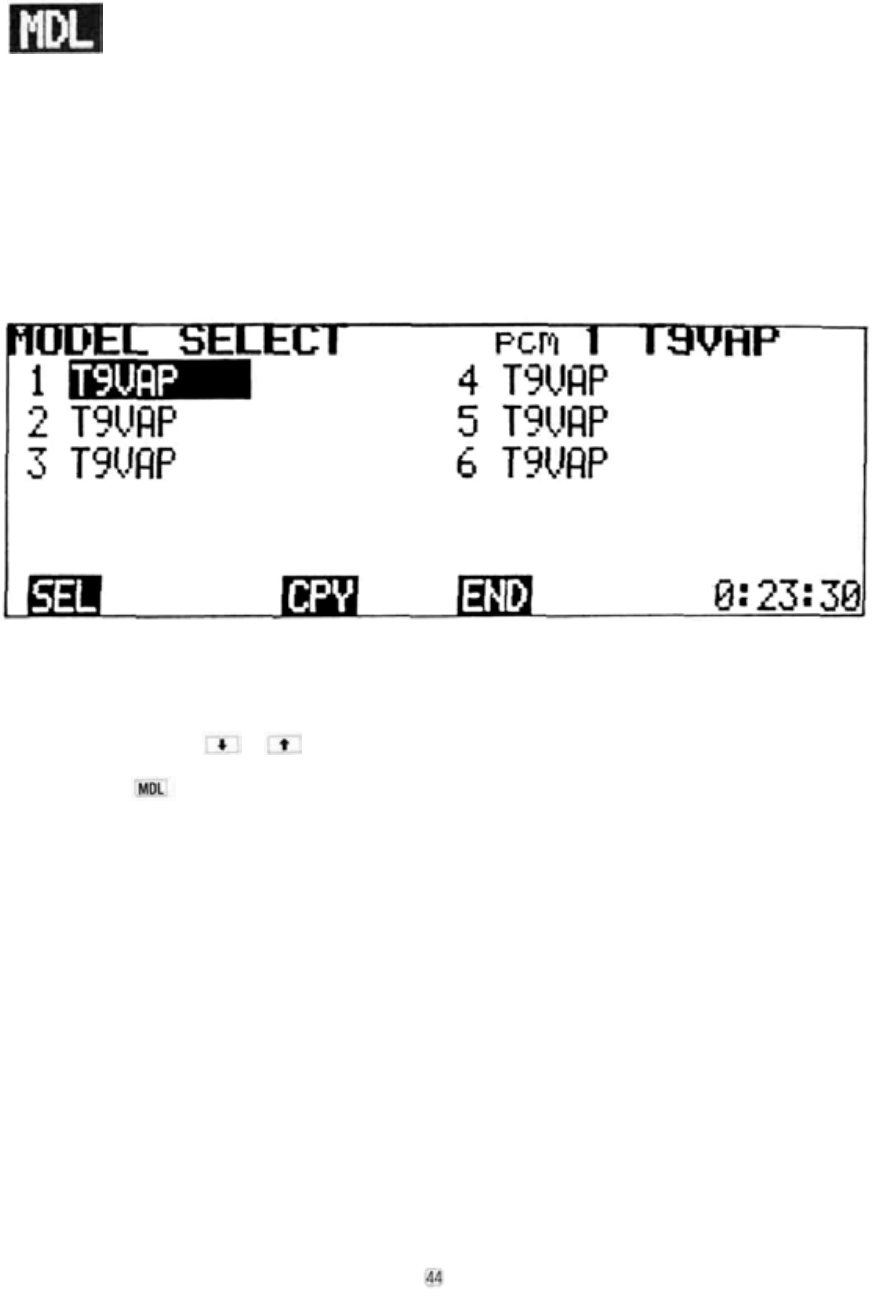

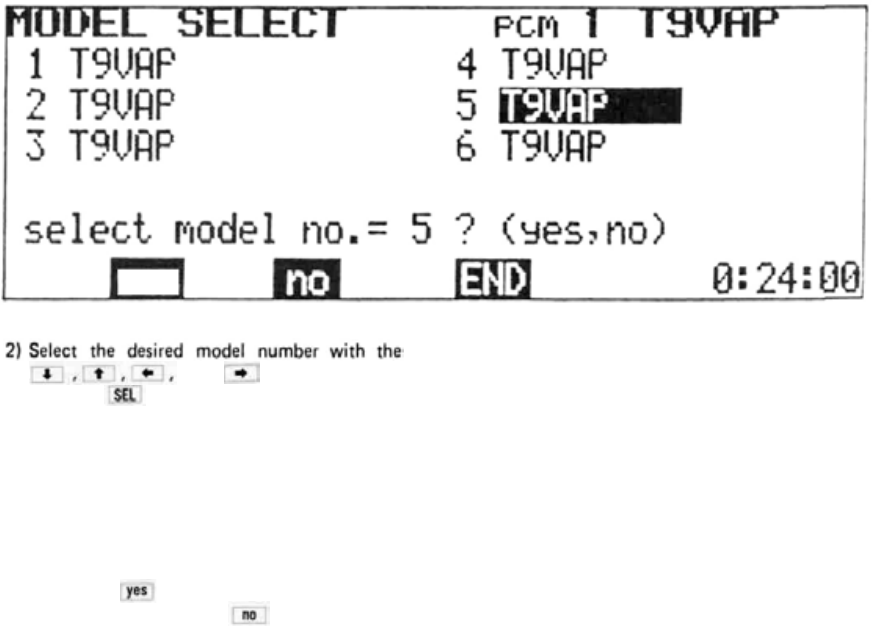

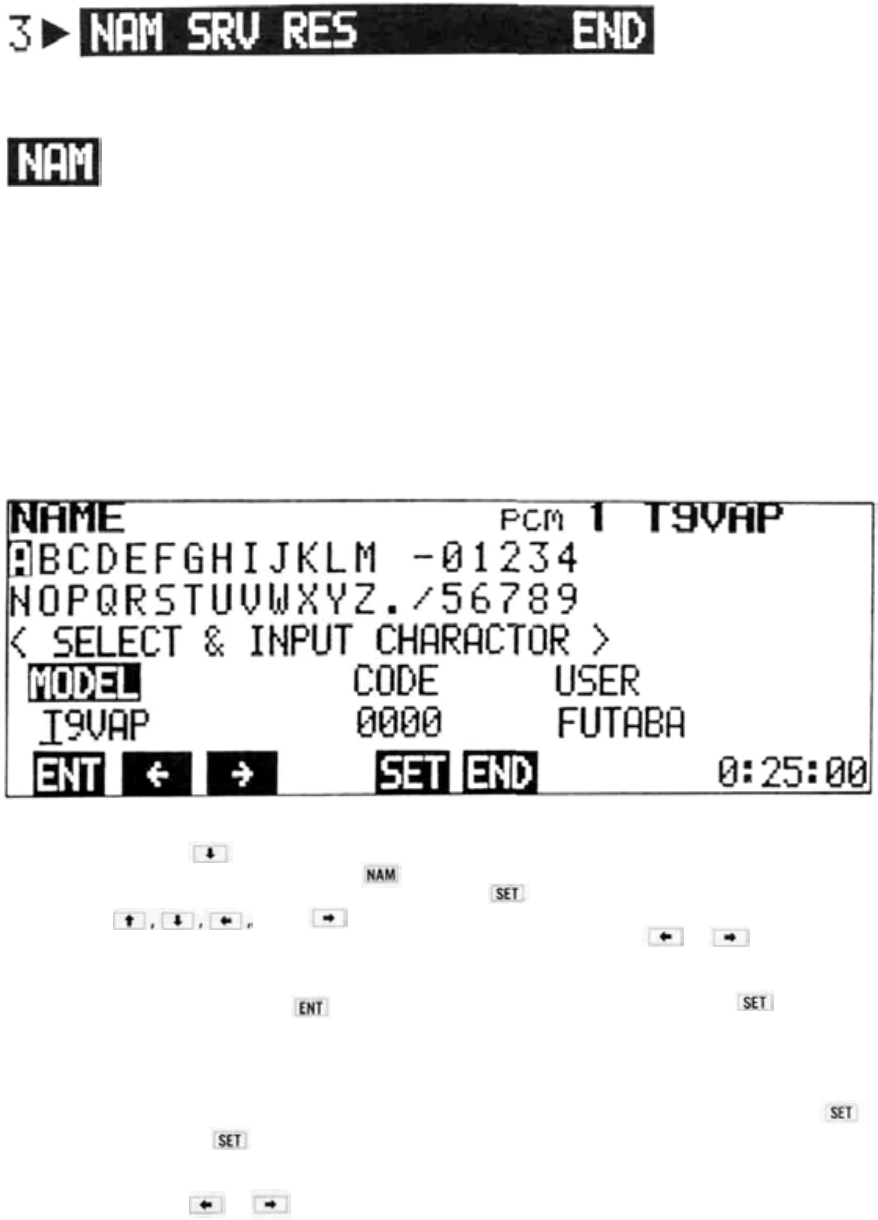

• Programming for up to six different models (in-

cluding model name) can be stored in the trans-

mitter memory. Memorized data is protected

by a 5 year lithium battery.

• Accessory "sub-trimmers" are provided on the

transmitter front for convenient field

adjust-

ment of frequently-used functions.

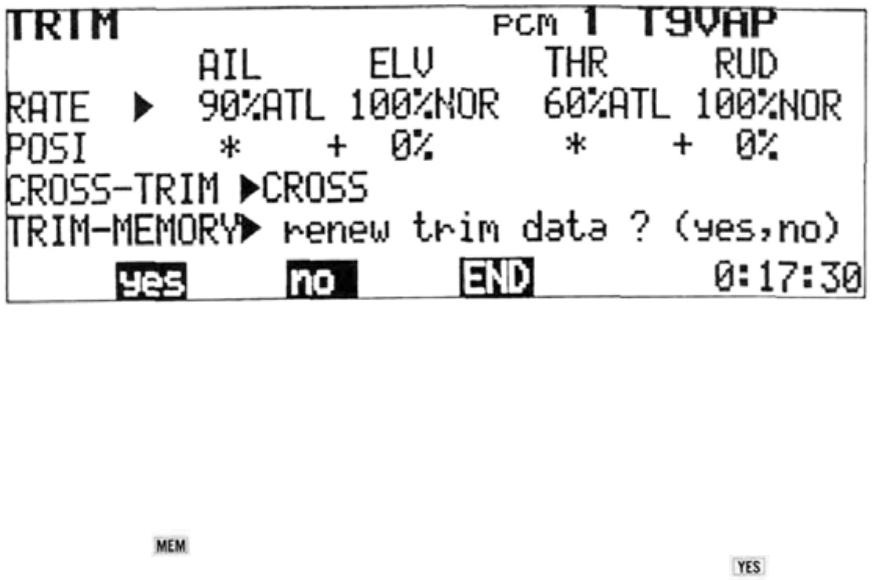

• Trim positions for each model can be memo-

rized by the Trim Memory function, allowing

the

trim

levers

and sub trimmers

to

be

returned

to neutral. Neutral positions can be reproduced

in the future, or copied onto another model

program if desired.

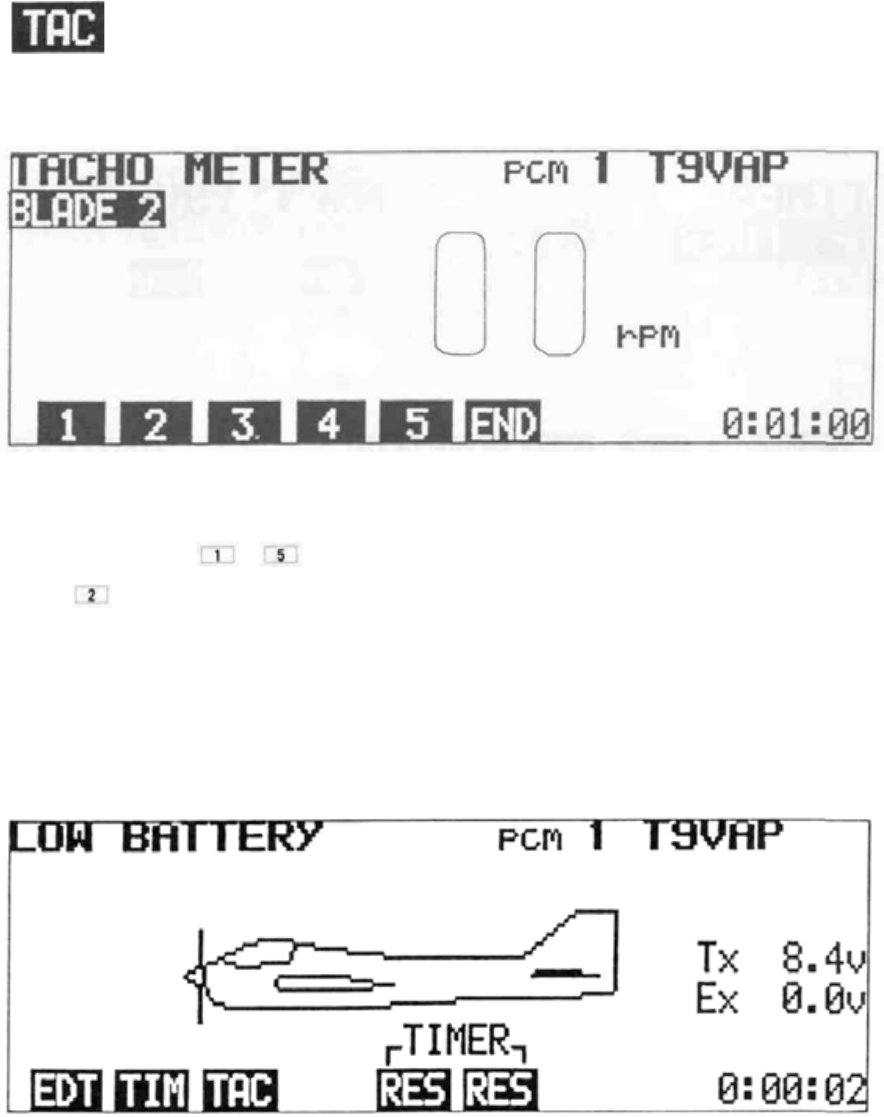

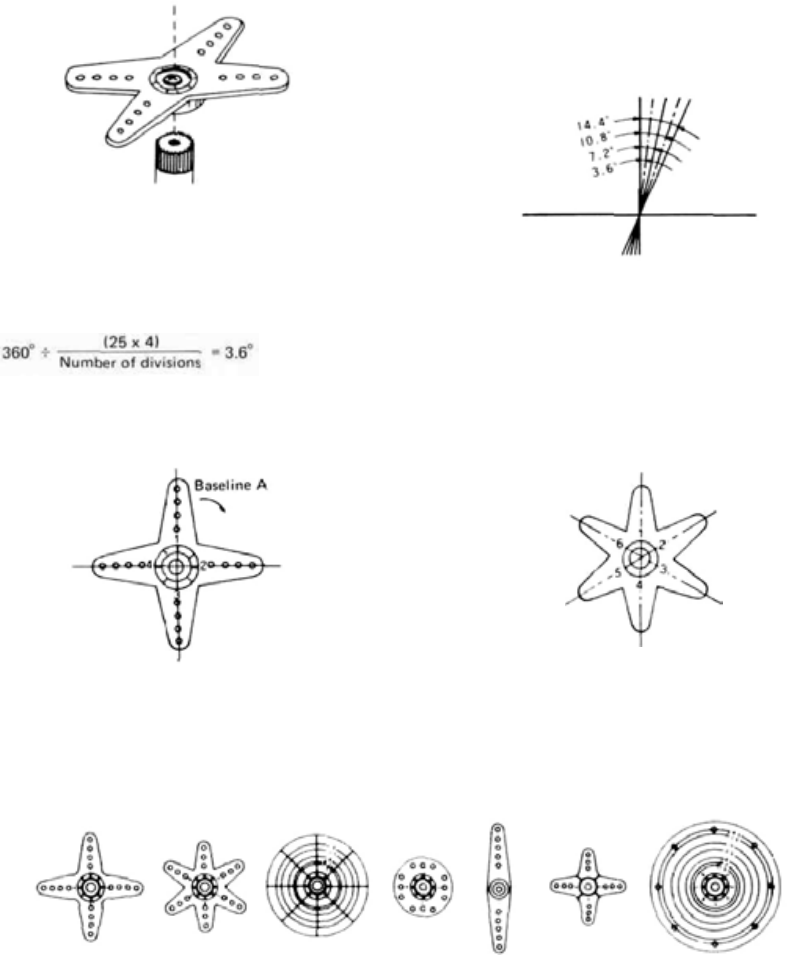

• The Tachometer function measures engine

rpm

by means of a built-in sensor.

• Speed can be measured for 1 to 5 bladed

propellers.

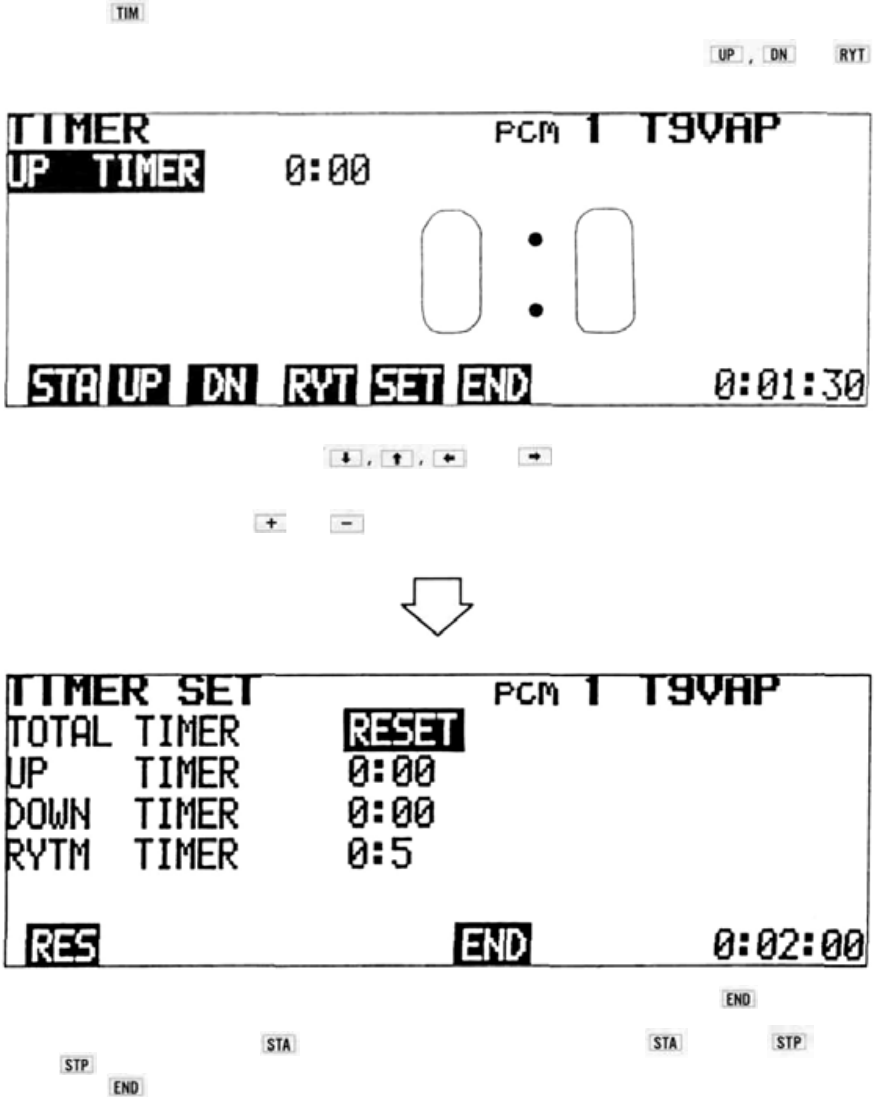

• Digital alarm/timer has UP, DOWN, and

RHYTHMIC timing modes

• Integrating (Total) Timer monitors total trans-

mitter ON time.

• Ball bearing open gimbal sticks, angled switches,

and "human-engineered" transmitter case en-

hance the feeling of comfort and precision in

transmitter operation.

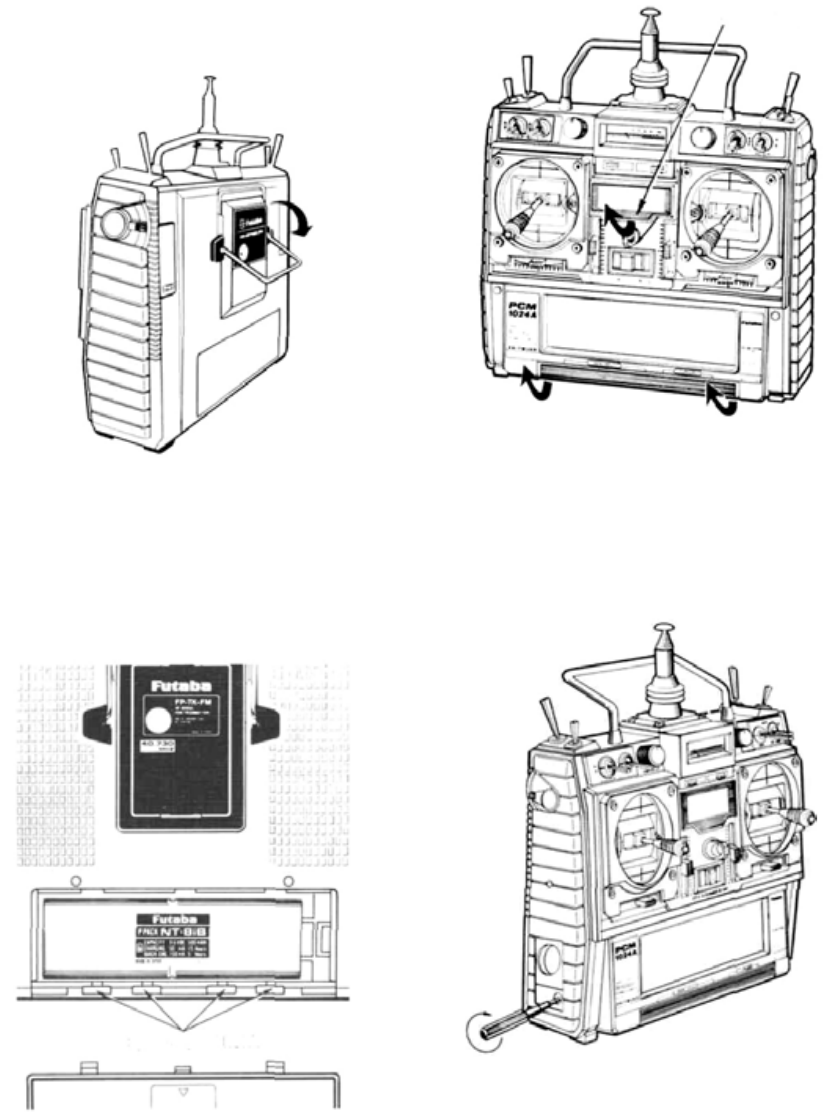

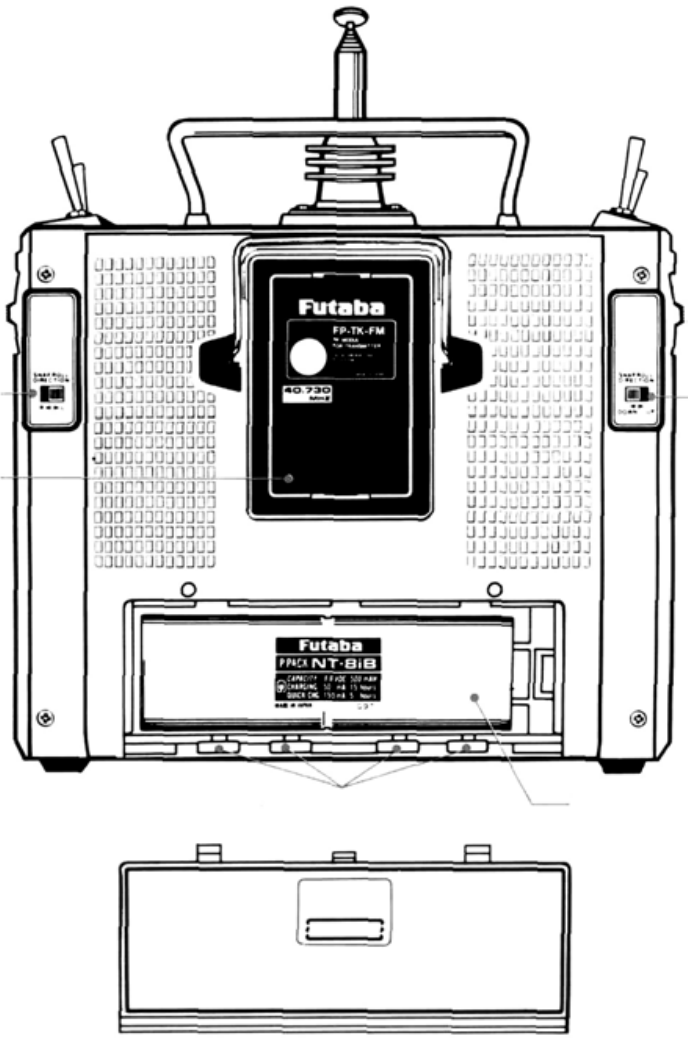

•"Quick

Change"

Nicd

battery

pack

is

easily

accessable by means of a convenient panel on

the transmitter back.

• Power Off function turns off the transmitter

power automatically if the controls are not

operated for 30 minutes.

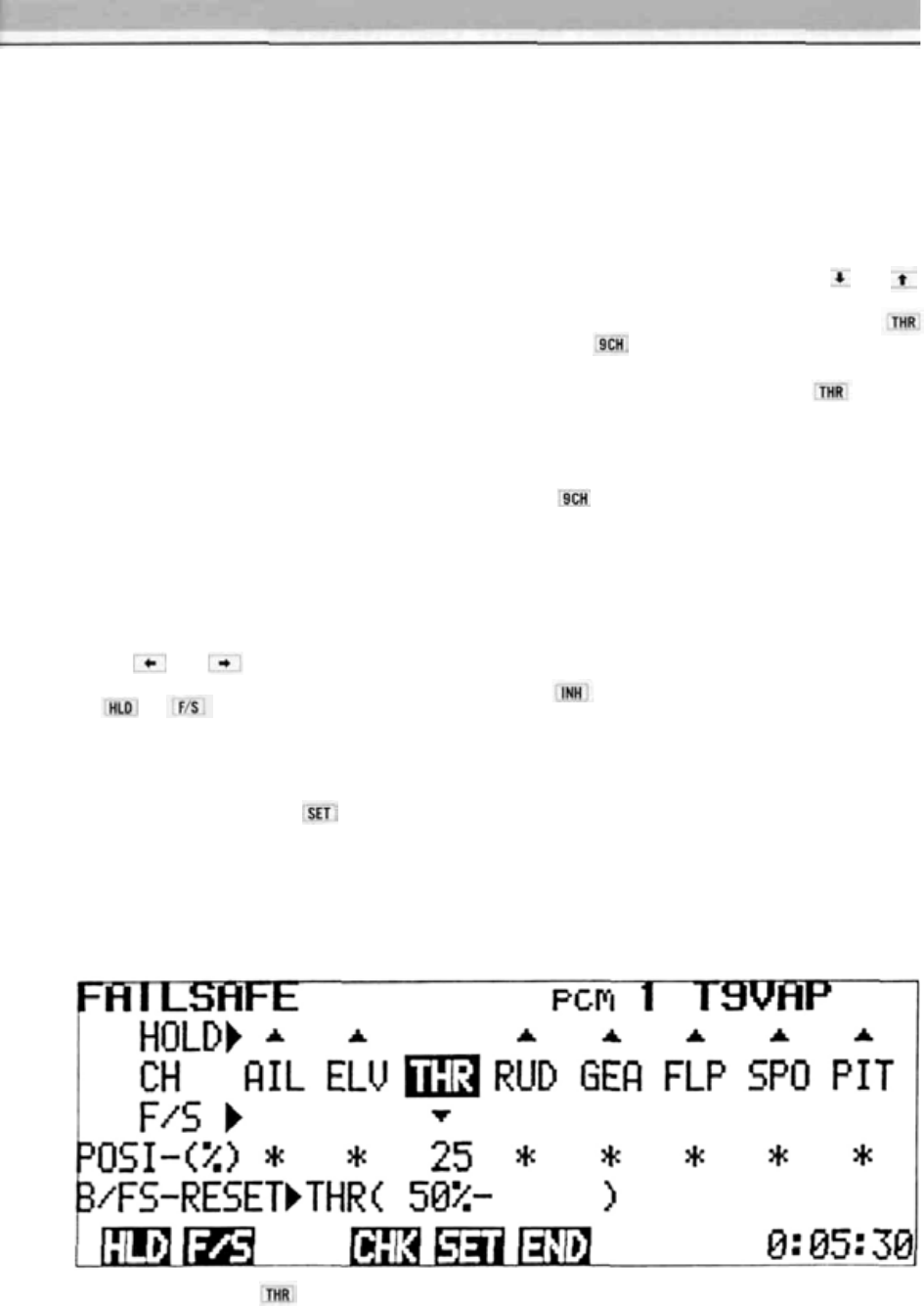

• PCM or standard PPM operation can be se-

lected. (Allows operation of standard FM

receivers on the same frequency.)

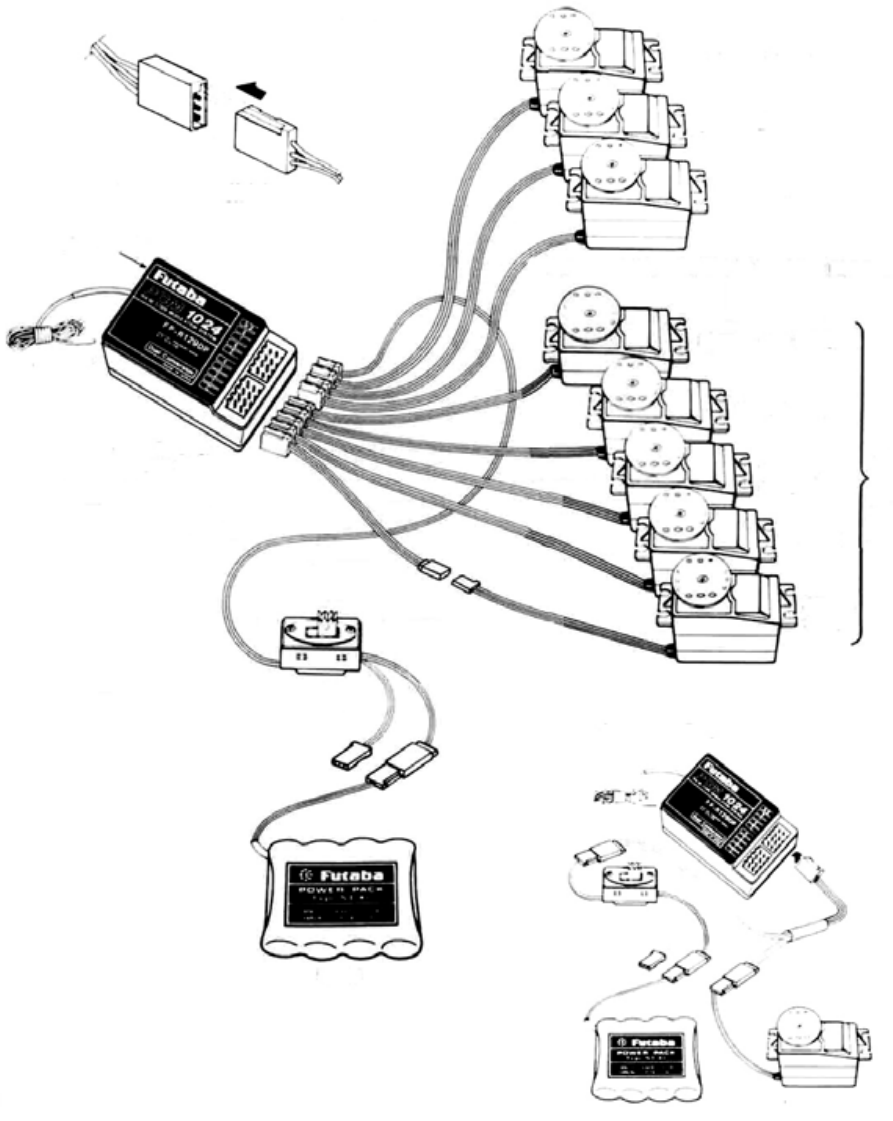

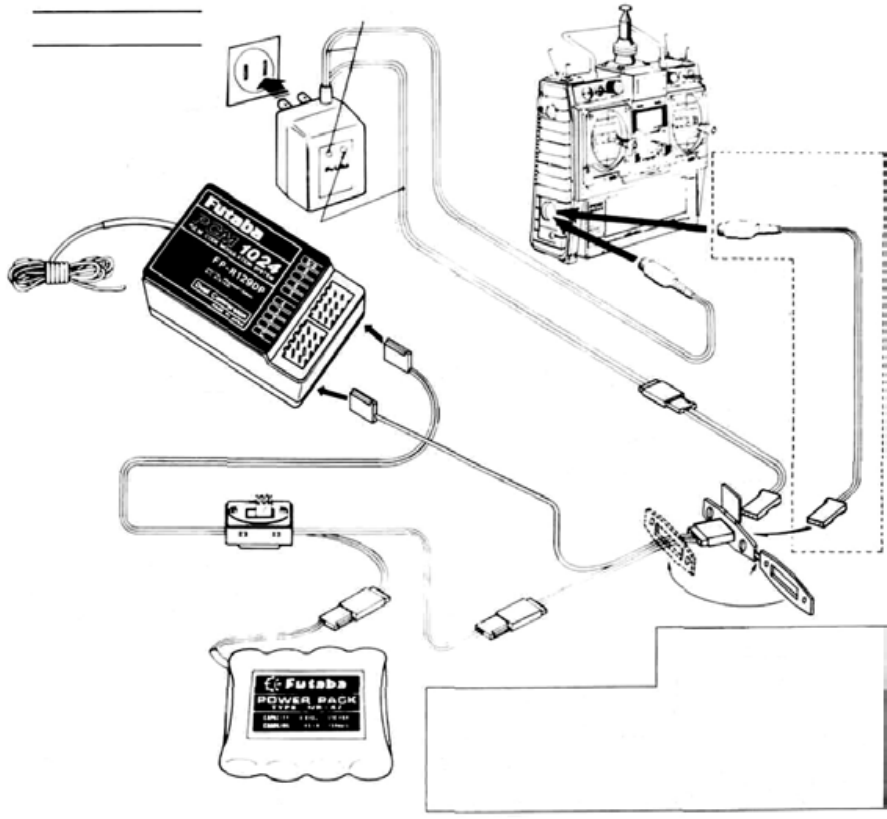

• DSC (Direct Servo Control): The

DSC

cord

allows operation

of

all

servos

without

turning

on the transmitter. The voltage of the trans-

mitter and receiver Nicd batteries can also be

read simultaneously using the cord.

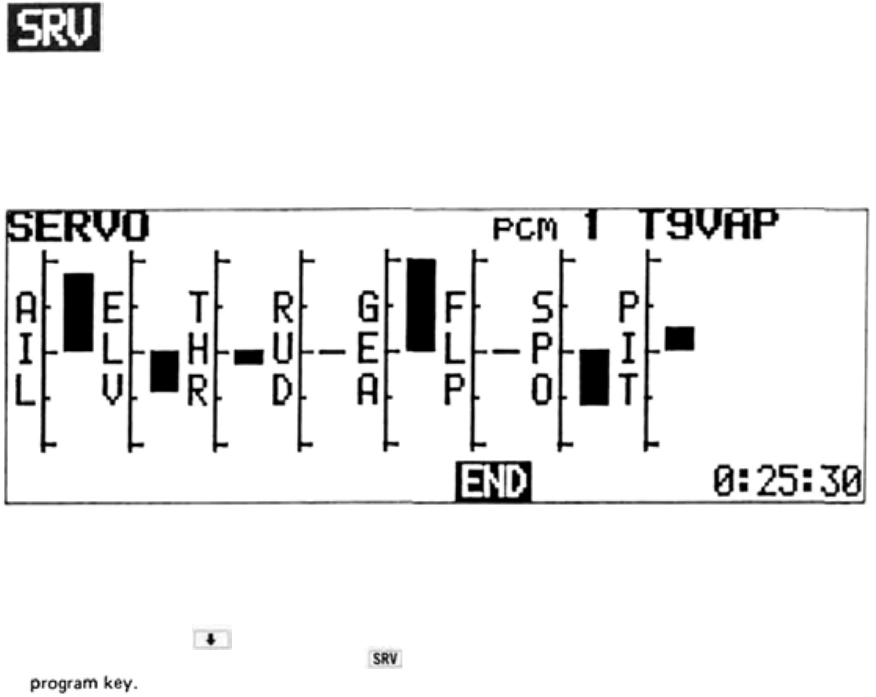

• Servo reversing is available on all channels.

•Auto

Dual Rate: If desired,

aileron, elevator,

and rudder dual rate can be turned ON and

OFF

automatically, according to throttle stick

position.

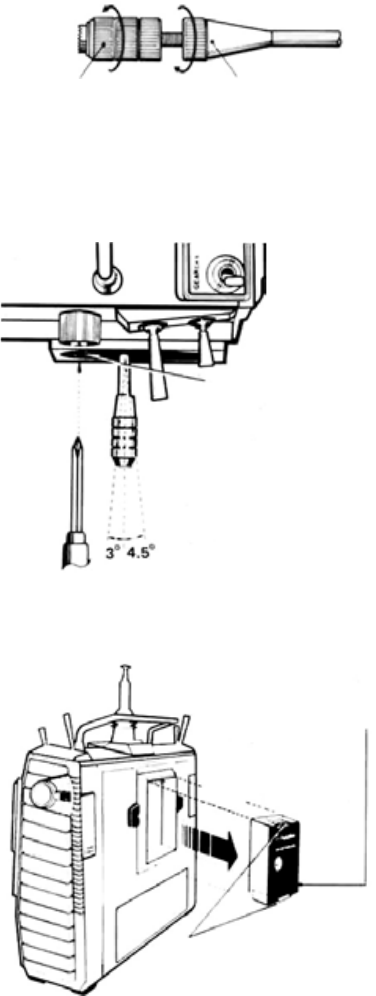

• Stick length and angle is easily adjusted.

• Knobs and levers are conveniently located.

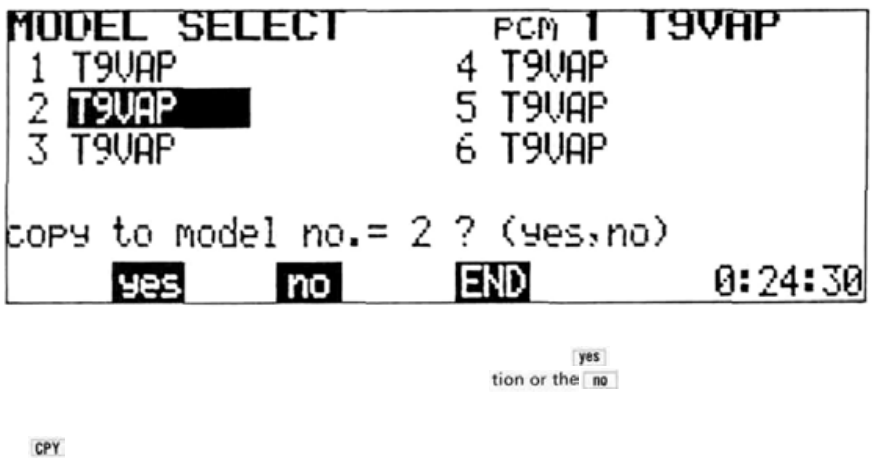

[1]