55

2

EU

1

3

FR

4

P O I N T E R

Spokehead

Hubcapscrew

Leading

spoke

(inward

head)

Trailingspoke

(outward

head)

A T T E N T I O N

Mounting

2.Thewheel

Wheellacing

Thenumberoftimesthatthespo-

kesarecrossedoverdependsenti-

relyuponthesizeoftherim.

Allrims india-

meter

pattern. All

wheelsmustbelaced

pattern.

Duetothehightorsionalstrength

ofthehubcasing,theuseofare-

versedlacingpatternonthebrake

diskside(DBversions)isnotne-

cessary.

larger than24"

mustbelacedinatwo

cross 24"andsmaller

sized upina

onecross

Further detailedinformation

withregardstowheellacingcan

befoundinthe Appendix.

Theleadingspokesarelacedso

thatthespokeheadalwaysfacesin-

wards.Thetrailingspokesarelaced

sothatthespokeheadalwaysfaces

outwards. Allspokesshouldbe

crossedovereachother.

Rimsaremanufactureredindife-

rentways. Thetypeofnipplehole

patternmustbedeterminedbefore

lacingthewheelasthiswillrequi-

readifferentlacingmethodtobe

followed.Inpicture1the

Europeannippleholepattern(EU)

isshown. Thefirstspokeholebe-

hindthevalveholeliestothedi-

rectionoftherighthandhubflange

(payattentiontotherotationaldi-

rectionoftherim).

Thewheellacingmethodisdeter-

minedbythenippleholepattern.

Thecorrectlacingmethodforboth

typesofholepatterncanbefound

intheappendix.

Rotatingthehubwhilstwheelbuil-

dingwillbeeasierwhenthe

RohloffSPEEDHUB500/14isin

gear#11. Thisgearcanbeselected

bypullingthehubcables(internal

gearmech),orturningthehexago-

nalpegonthegeartransferbox

withan8mmwrench(externalge-

armech).

Rotationdirection

Inpicture2theFrenchnipplehole

pattern(FR)isshown. Thefirst

spokeholebehindthevalvehole

liestothedirectionofthelefthand

hubflange(payattentiontothero-

tationaldirectionoftherim).

Ifthespokeholesoftherimareall

centrallydrilled,thenthelacing

methodforaEuropeannipplehole

patternshouldbefollowed(seeap-

pendix).

Spokesmustnotcrossdirectlyover

thehubcapfixingscrewson

wheelswhichare24”orsmallerin

diameter!

Rotationdirection

Valvehole Valvehole

56

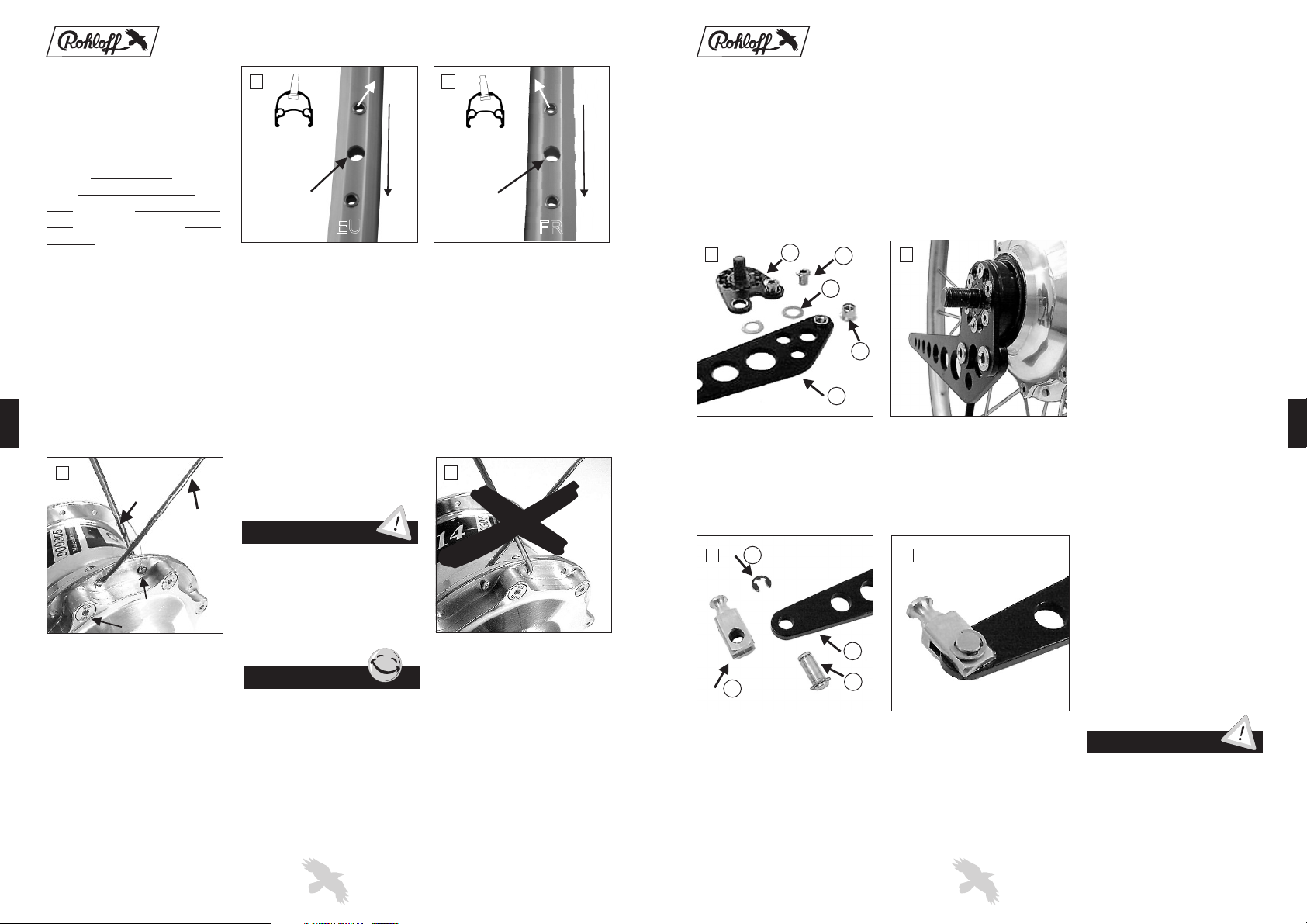

C

B

A

E

D

E

G

H

F

1 2

3 4

F

G

H

Locatingfork

Securingpinwithcirclip

Circlip

A

B

C

D

E

Threadedbush

Washer

Mountingbolt

Axleplate(CCor TS)

Longtorquearm

OntheCCversions,thelocating

forkmustalsobeattachedtothe

torquearm.Placetheforkedend

overthetorquearm,pushthe

securingpinthroughthetwoparts

andsecuretheotherendinplace

withthecirclip. TS Versionsmust

haveatorquearmclampmounted

insteadofthelocatingfork.

Makesurethatbothcirclipssit

correctlyontothesecuringpin.

Pushthethreadedbushesthrough

thetorquearmfrombehind.Place

awasherovereachofthebushes

andthentheaxleplateoverthese

washers(pictures1and2showthe

TSversion).Securethetwoparts

togetherwiththemountingbolts.

(M8 0.75-5mmallenkey,

tighteningtorque:7Nm/61in.lbs.).

x

3. Mounting additional parts

The comes with additional parts according to the corresponding version. These parts

must be mounted first.

Rohloff SPEEDHUB 500/14

3.1 Standard long torque arm

All versions not carrying the codes OEM or OEM2 come included with the long torque

arm for supporting the torque. This must be mounted to the axle plate.

Rohloff SPEEDHUB 500/14

A T T E N T I O N

Mounting