cutting threads. The use of machine taps is recommended.

The tap is clamped into the chuck. The electronics are

sensitive and should be handled with utmost care to avoid

breaking the tap – particularly when cutting threads into

blind holes.

Important! When cutting threads, use low speeds only.

Important note for machines with clockwise and anti-

clockwise rotation.

Reassembly of drill chuck:

Caution!

Before disassembling and reassembling the drill chuck,

disconnect the machine from the power supply, or re-

move the mains cable module (5) from the grip using

the locking device button (4).

Caution!

Before disassembling and reassembling the drill chuck,

always move the reversing switch (3) to the LOCK posi-

tion. By doing so, you eliminate the risk of accidentally

triggering the full wave switch (1).

If a faulty chuck has to be replaced, please check whether

the chuck is secured to the drill spindle with a safety

screw. This screw must be removed first (Caution! Left-

handed screw! Turn clockwise!).

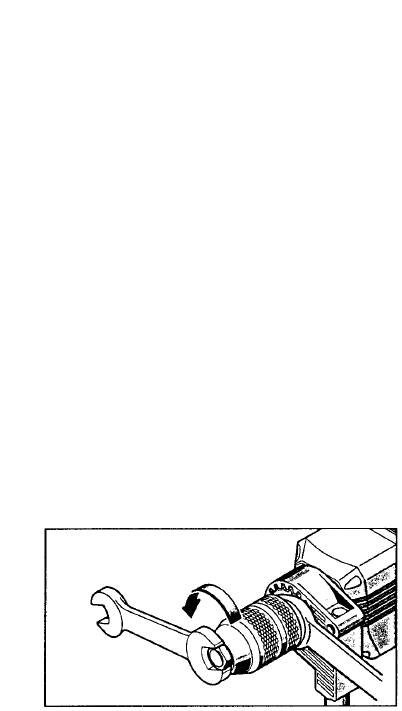

Screw off the drill chuck as shown in the picture (with an

open-end wrench).

For reassembly, proceed in the opposite direction.

Caution: Before fitting a new chuck please clean the end

faces on the chuck and drill spindle.

Tighten the new chuck securely (30 Nm). Secure the chuck

with the safety screw is there is one (Tighten the safety

screw in anti-clockwise direction).

Caution!

It is still possible, especially when there is no safety

screw, that the chuck comes off the drill spindle when

it is turning in the anticlockwise direction. For this rea-

son, when changing the chuck ensure that it is fitted

onto the spindle perfectly.

Caution!

Put the reversing switch (3) in the LOCK position be-

fore disassembling and reassembling the drill chuck,

disconnect the machine from the power supply, or re-

move the mains cable module (5) from the grip using

the locking device button (4).

Always make sure that the chosen speed is correct for

the purpose for which you are using the machine.

When drilling match speed with type of material and drill.

Use tool steel twist drills for soft materials such as wood

and plastics; high speed twist drills for steel and iron.

When drilling match speed to material and the diameter of

the drill.

Use tool steel twist drills for soft materials such as wood

and plastics; high speed twist drills for steel and iron.

Also make sure that, using a gear-rim-chuck, the drill

chuck key is never fastened to the drill with chains,

strings or by similar means. Be sure that the workpiece

cannot be taken along by the drill.

Maintenance

The machine's motor has life-time lubrication and requires

no special maintenance. However, should you operate the

machine on a continuous basis over long periods of time

we recommend that you send us the machine for thorough

cleaning and an inspection. This will spare you unneces-

sary repair expenses and increase the machine's service

life. If you always clean the ventilator of dust after each

operation, the motor will enjoy an ever longer service life.

Uniform ventilation is essential for a long service life.

Replacing carbon brushes

Our service personnel will do this and all other servicing

work fast and professionally.

Mains cable

Replace damaged mains cables immediately. This is an

uncomplicated procedure thanks to the latest cable mo-

dule (5). Press both locking buttons (4) and pull the cable

module (5) out of the grip. Insert and lock the new mains

cable module. Cables with different lengths are available

as optional accessories.

Only use the mains cable module for KRESS power

tools! Do not attempt to operate other electrical ap-

pliances with it!

Auxiliary handle

For safety reasons the side handle should always be used

when working with the drill. It guarantees safe, wander-free

guidance of the drill, and at the same time precise adjust-

ment of the drilling depth with the depth stop.

Tighten the draw spindle on the auxiliary handle properly.

This is the only way to ensure that the auxiliary handle

cannot turn on the collar or come off the appliance.

Standard accessories

Side handle with depth stop

Noise/vibration information

Measured values correspond with EN 50144.

Sound pressure level: 73

+

3

dB (A)

Sound power level: 86

+

3

dB (A)

Work place emission value: 76

+

3

dB (A)

Operators require noise protection equipment.

The weighted acceleration ist typically smaller than 2,5 m/s

2

.

Environmental protection

Kress takes back used machines for resource saving recyc-

ling. Due to their modular construction Kress machines can

be very easily broken down into their recyclable basic ma-

terials. Hand in your old Kress machine at a dealer or send

them directly to Kress.

Subject to change without notice.