Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

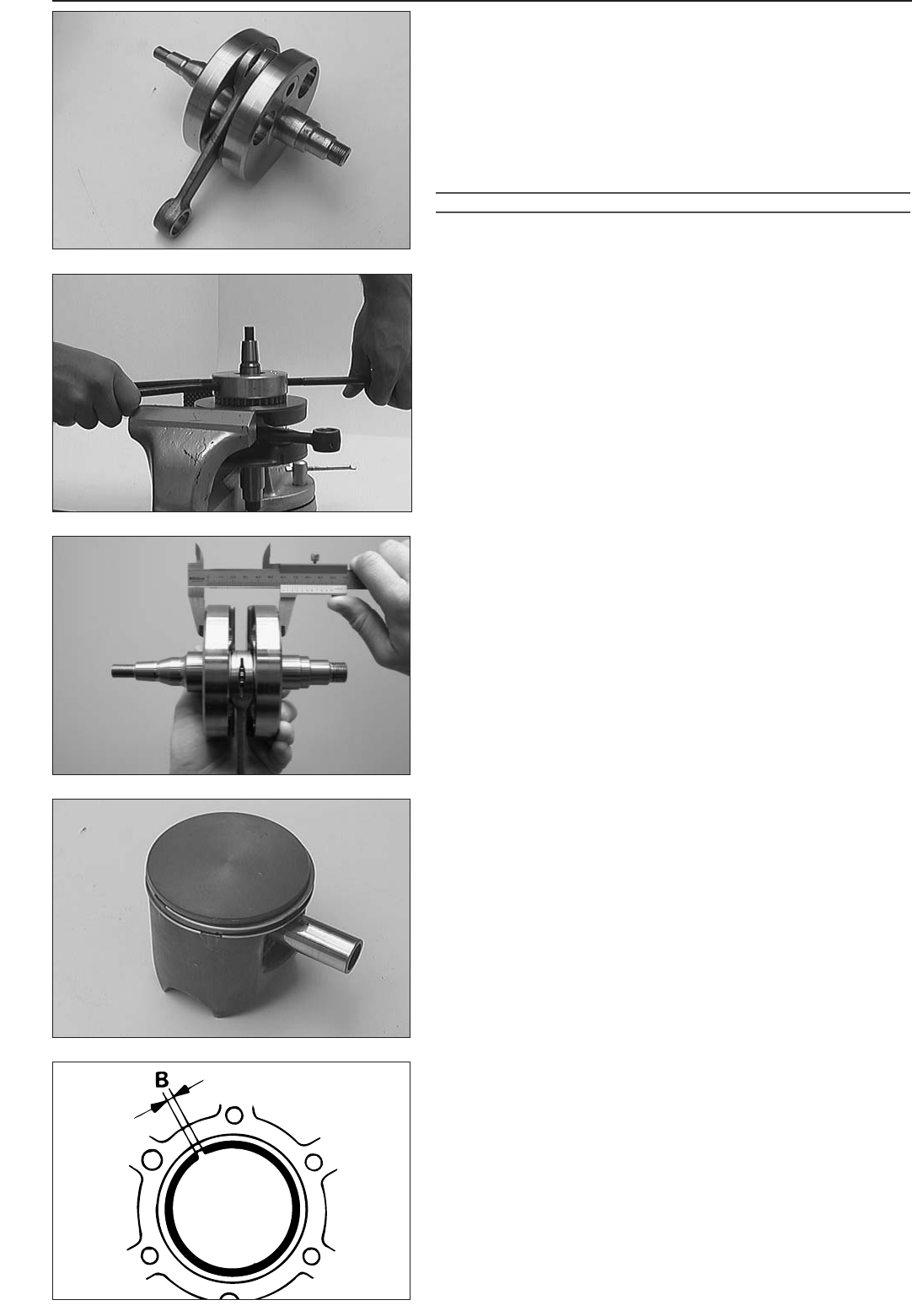

Crankshaft

– When replacing the roller bearing, the inner crankshaft ring must also

be renewed.

– Heat special tool 584.29.037.040 on a heating pad up to approx.

150°C and slip it on the inner ring immediately. Press the special tool

together tightly so as to obtain a good heat transfer and pull the inner

ring off the crankshaft.

–To mount the new inner ring, heat the special tool again to approx.

150°C, engage the inner ring and slip it on the crankshaft journal

immediately.

!

CAUTION

!

N

EVER CLAMP THE CRANKSHAFT WITH A STUD OR WEB IN THE VICE, AND NEVER TRY

TO KNOCK THE BEARING INNER RING FREE

. THE CRANKSHAFT WEBS MAY BE

COMPRESSED AND THE CONROD PLUG AND BEARING MAY BE DAMAGES

, THEREBY

MAKING THE CRANKSHAFT UNUSABLE

.

NOTE: Distance adjustment of the main bearings is not requested.

Crankshaft webs – measure outer dimension

Crankshaft webs – measure outer dimension with a sliding caliper as

illustrated.

Crankshaft webs – outer dimension = 60 mm ± 0.05 mm

Piston

If a used piston is to remain in service then the following should be

checked:

1. Piston running surface: Check for pressure marks (seizing marks) minor

friction marks can be removed with a fine abrasive stick.

2. Piston ring grooves: The piston rings must not get jammed in the

grooves. For cleaning the grooves, use an old piston ring or abrasive

paper (grain size 400).

3. The piston ring locating pins must be firmly seated in the piston and

must not be worn out.

4. Check piston rings for wear and check end gap.

Piston ring end gap

– Insert piston ring into the cylinder and adjust. Piston ring must be

approx. 10 mm (1/2 inch) from top of cylinder.

– The end gap

B can now be checked with a feeler gauge.

Piston ring end gap: max. 0.40 mm (0.015 in)

NOTE: If the end gap is greater check piston and cylinder for wear. If

piston and cylinder wear are within the permitted tolerance limits, replace

the piston ring.

5-4C