6.5 T

ROUBLESHOOTING THE LIFEPULSE SYSTEM SENSORS

If the heart rate reading is erratic or missing, do the following:

• Dry the hands if necessary to prevent slipping.

• Apply hands to all four sensors, located at the front and back of the hand grips.

• Grasp the sensors firmly.

• Apply constant pressure around the sensors.

6.6 HOW TO

ADJUST AND TENSION THE STRIDING BELT

Do not move treadmill or place hands under treadmill while it is plugged into an electrical outlet!

THE BELT TENSIONING BOLTS

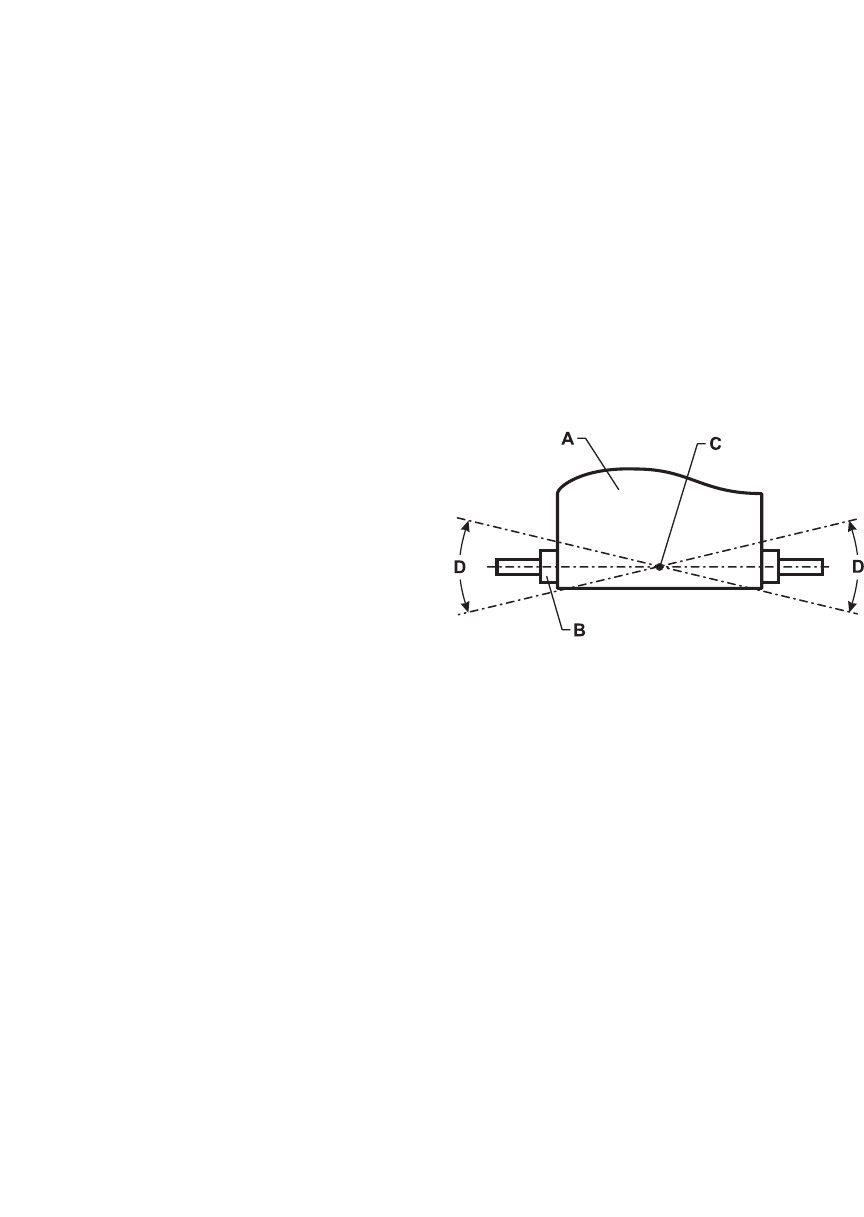

A 5/16-inch hex key wrench is required for this task. The Life Fitness Treadmill has access holes in the

rear roller guards which allow access to the tensioning bolts. These tensioning bolts make it possible to

adjust the tracking and centering of the striding belt (A) without removing the guards.

NOTE: It is extremely important that the treadmill be

correctly leveled prior to any tracking adjustments. An

unstable unit may cause striding belt misalignment. See

the topic titled "How To Stabilize the Life Fitness

Treadmill" in the Section 1.2, titled Set Up, prior to

attempting any rear roller adjustments.

Before proceeding, it is helpful to visualize the REAR

ROLLER (B) pivot point (C). Each adjustment made to

one side of the ROLLER must be met with an equal

and opposite adjustment (D) to the other side of the

ROLLER to maintain an ideal belt tension at the pivot

point.

TRACKING (CENTERING) A STRIDING BELT

Two people are needed to perform this procedure.

1 Locate the two access holes to the belt tensioning bolts on each of the rear roller guards.

2 One person stands on the side rails of the treadmill and straddles the belt. This person presses

the MANUAL workout and sets the belt speed to 2.5 MPH (4.0 KPH).

3 If the striding belt has moved to the right, the second person turns the right tension bolt a quarter-

turn clockwise and then turns the left tension bolt a quarter-turn counter-clockwise to make the

striding belt track back to the center of the roller.

If the striding belt has moved to the left, turn the left tension bolt a quarter-turn clockwise and then

turn the right tension bolt a quarter-turn counter-clockwise to make the striding belt track back to

the center of the roller.

4 Repeat the adjustments until the striding belt appears centered. Allow the machine to continue

running for several minutes at 4.0 MPH. (6.4 KPH) to observe if tracking remains

stabilized.

NOTE: Do not exceed one full turn of the adjusting screws in either direction. If after one full

turn the belt does not track properly, contact Customer Support Services. The phone numbers

are listed in Section 6.7, titled How to Obtain Product Service.

63