29

Use rigid or flexible connection pipes

which comply with applicable regula-

tions.

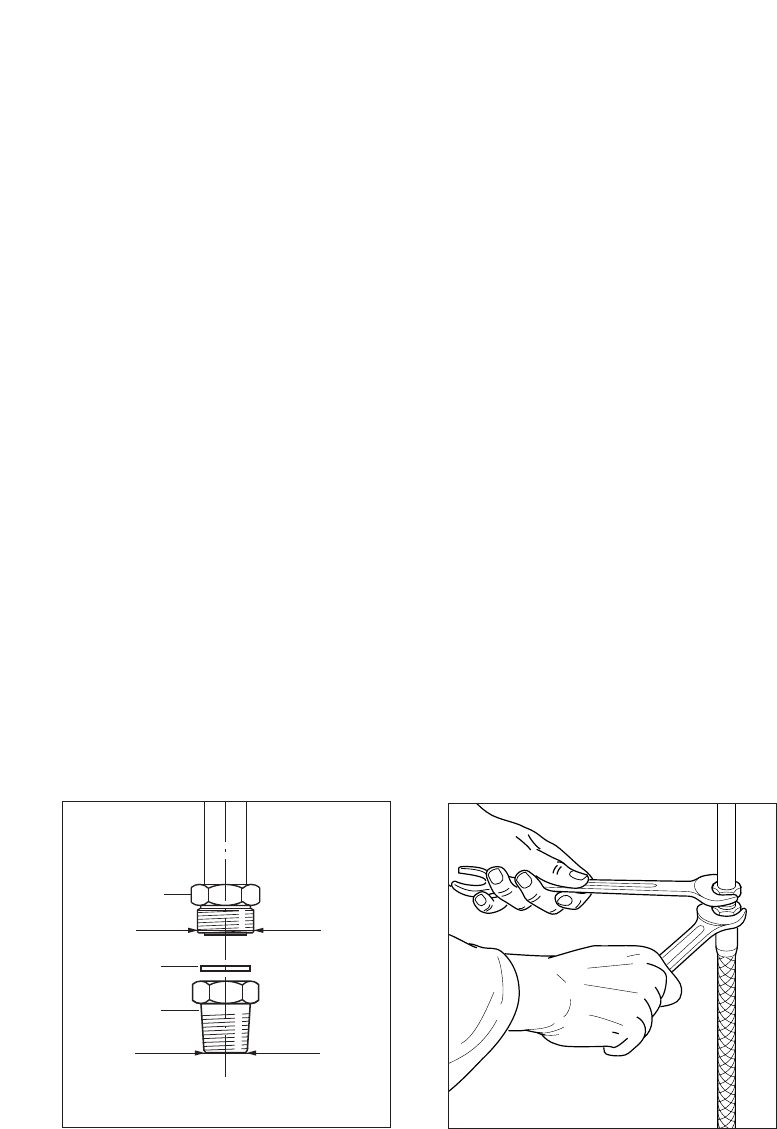

If compression fittings are used, tighten

firmly using two spanners (fig. 8.3).

In particular, make sure that:

– the flexible hose does not come into

contact with any parts of the cooker

with surface temperatures in excess

of 70˚C;

– the flexible hose does not exceed 75

cm in length and does not come into

contact with sharp edges or corners;

– the hose is not under tension or twist-

ed and is not kinked or too tightly

bent;

– the connection with rigid metal pipes

should not cause stresses to the gas

ramp.

– we advise replacing the gasket on the

slightest sign of deformation or imper-

fection.

– the hose can easily be inspected

along its entire length to check its

condition; hoses should replaced

after a maximum of three years.

– the cylinder cock or the supply cock

immediately ahead of the appliance is

closed whenever the cooker is not in

use.

The fitting (fig. 8.2) is made up of:

A - Gas train terminal fitting (rh or lh)

B - Gasket

C - Conical connector

Fig. 8.3

IMPORTANT:

The gasket “B” (fig. 8.2) is the element

that guarantees the seal in the gas con-

nection. It is recommended that it be

replaced whenever it shows even the

slightest deformation or imperfection.

To replace the conical connector “C” or

to screw the connecting tube it is neces-

sary to operate with 2 spanners (fig. 8.3).

After connecting to the mains, check

that the couplings are correctly

sealed, using soapy solution, but

never a naked flame.

B

C

ISO 7-1

ISO 228-1

A

Fig. 8.2