4

1. Saf ety measures

Carefully read the oper ating instr uctions bef ore assemb ling

and star ting. The appliance m ust not be used b y persons

who are not thoroughly acquainted with the instr uctions

handbook (oper at ing instr uctions). Chi ldren and persons

under the age of 16 cannot use the pump and m ust be

k ept w ell a w a y from the appliance when it is connected.

The user is liab le to w ards third par ties in the area where

the appliance is in oper ation.

While the pump is operati ng per sons m ust

not be in the liquid to be pumped.

The pump ma y be connected onl y b y

means of a saf ety s witc h f or fault currents, with

a rated opening current up to 30 mA and a soc ket

with an ear th contact installed in conf ormity with

the regulations.

Pr otection: at least 10 Amps.

Oper ation in s wimming pools and g arde n ponds is

admitted.

F or other oper ation, the pro visions in conf or mity with

the standard VDE 0100 par t 702 m ust be respected.

CA UTION: Bef ore c hec king, connect the pump and

the system with no v olta g e!

Replacing the line connecting up with the mains

requires using special tools and theref ore ma y be

done only b y the man uf acturer or its ser vice engineers .

The pump ma y oper ate only with a pipe connecting

the appliance (e xtension) that is no lighter than a

ru b ber hose mod. H07 RNF in conf or mity with the DIN

57282 or DIN 57245 standard.

(F or y our saf ety)

The v oltage (230 V olt s alter nati ng current) i ndi-

cated on the pump’ s r ating plate m ust correspond

to the a v ailab le mains v oltage .

Bef ore star ting it is necessar y to mak e sure b y ha ving a

chec k made b y qualified personnel that there are the

necessar y electr ical protection measures .

• Ear th connection.

• Ear thed neutr al.

• The saf ety s witch f or f ault currents corresponds to the

saf ety regulations of the electr icity board and functions

perf ectly .

• Plug connections m ust be protected from w ater . If there

is a r isk of flooding, plug connections m ust be placed

some where saf e .

• Definitely a v oid pumping agg ressiv e liquids and abr asiv e

products .

In the e v ent of the pump f ailing, repair w or k ma y only be

carr ied out b y th e repair w or kshops of the tec hnic al

ser vice . Only gen uine spare par ts m ust be used.

SUBMERSIBLE PUMP

18

It is notified that in conf or mity with the la w on product

liability

we cannot be held responsib le

f or the damage caused b y our appliance:

a) because of improper repairs not carr ied out b y the

personnel of the assistance points author iz ed b y us;

b) or if GENUINE SP ARE P AR TS are not used to replace

par ts;

c) or if the indications and pro visions giv en in the instr uc-

tions handbook are not complied with.

The same pro visions hold f or the accessor ies .

Resistance

The maxim um temper ature of the deliv er y liquid should

ne v er e xceed +35 ° C in contin uous oper ation.

Infiammab le , comb ustib le or e xplosive liquids cannot

be con ve y ed with this pump!

In par ticular , do not use engine fuels , de te rgents , or o ther

chemical products .

2. Use

CA UTION! Sector of use

“DRAINA GE” – To tr ansf er and empty fresh to

slightly polluted w ater from r ainw ater barrels and

casks .

“V OR TEX” – Po r tab le submersib le pump f or

discharge and w aste w ater with solids in suspen-

sion.

Also used as emergency pump , in case of o v er-

flo wing with m uddy w ater , t hanks to its large

suction filter .

To ac hie ve e xcellent motor cooling the pump

casing is pr o vided with a breather hole that enab les

water to flo w out.

The pump m ust be pr otected fr om running dr y .

Star ting

First put the pump into w ater and then

connect the plug.

The pump is ready f or use .

3. Bef ore star ting

Installation of y our canned motor pump is:

• fix ed with a fixd pipe , or

• fix ed with a fle xib le hose .

T ake care

When installing it is necessar y to tak e care that the pump

is ne v er fitted hanging from its deliv er y pipe , b ut is alw a ys

placed in a r aised position with respect to the bottom of

�

the w ell so that the m uddy bottom is not suc k ed up with

the w ater .

Ne v er handle or hang the pump b y g r ipping the po w er

supply cab le .

In pumps with a floating s witch, the latter is adjusted in

order to mak e immediate star ting possibile .

Note

The pump w e ll m ust ha v e minim um dimensions of

40x40x50 cm. so that the floating s witch can mo v e freely .

It is also possib le to use round, pref abr icated concrete

w ells with an inner diameter of appro x. 40 cm.

4. Maintenance instructions

Y our canned motor pump is a quality product, free from

maintenance . It has been subjected to r igorous final

chec ks .

Ho w e v er , f or a long ser vice lif e and contin uous oper ation,

we recommend constant care and regular chec ks .

• Bef ore e v er y maintenance job , disconnect the plug.

•F or tr anspor tab le use the pump should be w ashed with

clear w ater after e v er y use .

•F or fix ed installation it is recommended to chec k the

oper ation of the floating s witch e v er y 3 months .

• Using a jet of w ater , get r id of the fibre and spindly

par ticles that ma y get deposited in the pump’ s cassing.

• In the e v ent of e xcessiv e deposits in the pump cassing,

dismantle the inlet filter b y unscre wing the star scre w .

W ash the pump casing and fit the inlet filter bac k on.

•E ve ry 3 months remo v e the m ud from the bottom and

w alls of the w ell.

• Eliminate the deposits from the floating s witch, w ashing

it with fresh w ater .

• Protect the pump from frost.

CA UTION!

“DRAINA GE”

Special inst ructions: It is not suitab le f or pump ing:

se wa g e , sand y water .

The pump m ust ne ver run dr y .

The man ufacturer’ s warranty is n ull and v oid in

the e vent of dama g e to the pump caused b y it

running dr y .

“V OR TEX”

The pump m ust ne ver run dr y .

The man ufacturer’ s warranty is n ull and v oid in

the e vent of dama g e to the pump caused b y it

running dr y .

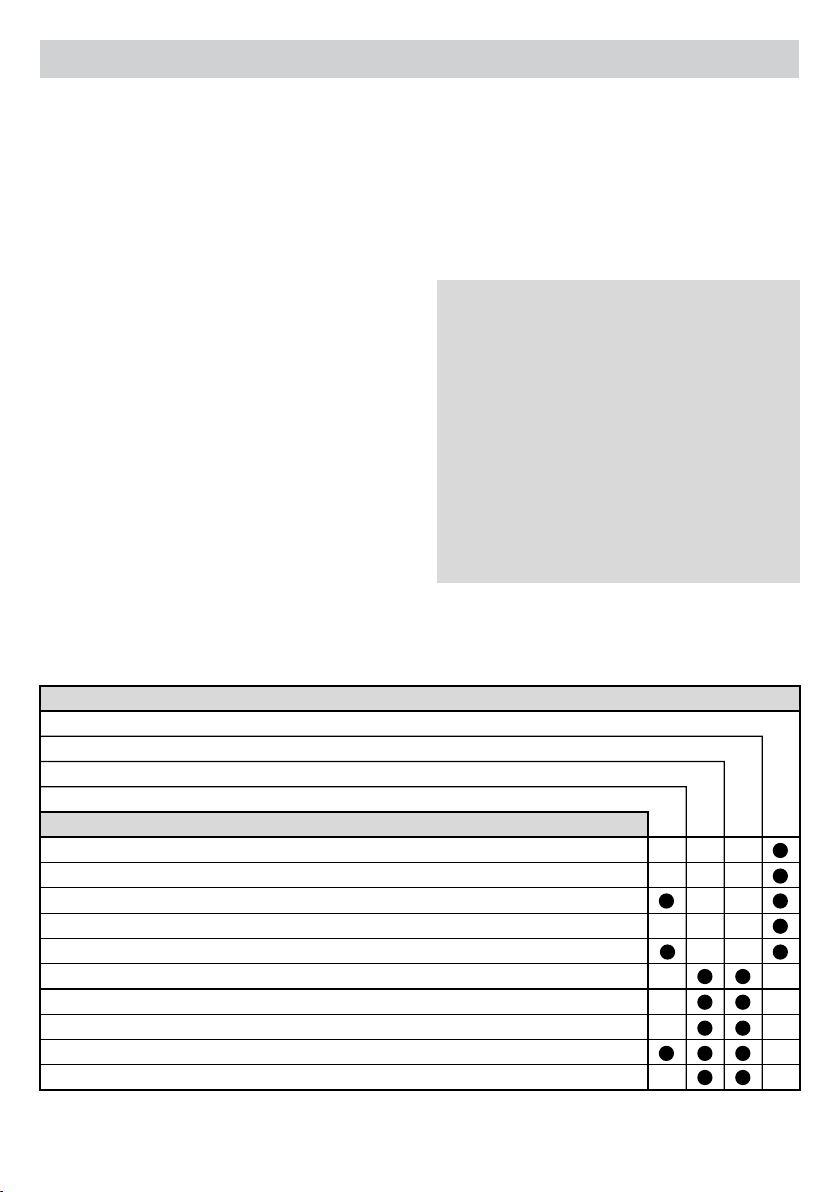

CA USES

The motor will not w or k

The motor w or ks , the pump will not con v e y

Insufficient flo w r ate

Repeated s witching off with disconnection of the protection s witch

TR OUBLE

No mains v oltage , the floating s wittch will not connect

Def ectiv e protection de vice

Motor protection disconnected, pump str aining/b loc k ed

Dr y oper ation protection disconnected, the w ater le v el has f allen too m uch

Def ectiv e pump

Clogged suction opening

Chec k v alv e b loc k ed or deliv er y pipe bent

Deliv er y pipe clogged

F oreign bodies in the pump , pump impeller b loc k ed

The pump r uns dr y

If it is not possibile to eliminate the tr oub le , please call our ser vice depar tment.

To a v oid dama g e during transpor t, please ship in the ORIGINAL P A CKING.

Tr oub leshooting T ab le

19

1. Saf ety measures

Carefully read the oper ating instr uctions bef ore assemb ling

and star ting. The appliance m ust not be used b y persons

who are not thoroughly acquainted with the instr uctions

handbook (oper at ing instr uctions). Chi ldren and persons

under the age of 16 cannot use the pump and m ust be

k ept w ell a w a y from the appliance when it is connected.

The user is liab le to w ards third par ties in the area where

the appliance is in oper ation.

While t he pump is operat ing per sons m ust

not be in the liquid to be pumped.

The pump ma y be connected onl y b y

means of a saf ety s witc h f or fault currents, with

a rated opening current up to 30 mA and a soc ket

with an ear th contact installed in conf ormity with

the regulations.

Pr otection: at least 10 Amps.

Oper ation in s wimming pools and g ard en ponds is

admitted.

F or other oper ation, the pro visions in conf or mity with

the standard VDE 0100 par t 702 m ust be respected.

CA UTION: Bef ore c hec king, connect the pump and

the system with no v olta g e!

Replacing the line connecting up with the mains

requires using special tools and theref ore ma y be

done only b y the man uf acturer or its ser vice engineers .

The pump ma y oper ate only with a pipe connecting

the appliance (e xtension) that is no lighter than a

ru b ber hose mod. H07 RNF in conf or mity with the DIN

57282 or DIN 57245 standard.

(F or y our saf ety)

The v oltage (230 V olt s alter nati ng current) i ndi-

cated on the pump’ s r ating plate m ust correspond

to the a v ailab le mains v oltage .

Bef ore star ting it is necessar y to mak e sure b y ha ving a

chec k made b y qualified personnel that there are the

necessar y electr ical protection measures .

• Ear th connection.

• Ear thed neutr al.

• The saf ety s witch f or f ault currents corresponds to the

saf ety regulations of the electr icit y board and funct ions

perf ectly .

• Plug connections m ust be protected from w ater . If there

is a r isk of flooding, plug connections m ust be placed

some where saf e .

• Definitely a v oid pumping agg ressiv e liquids and abr asiv e

products .

In the e v ent of the pump f ailing, repair w or k ma y only be

carr ied out b y th e repair w or kshops of the tec hnic al

ser vice . Only gen uine spare par ts m ust be used.

SUBMERSIBLE PUMP

18

It is notified that in conf or mity with the la w on product

liability

we cannot be held responsib le

f or the damage caused b y our appliance:

a) because of improper repairs not carr ied out b y the

personnel of the assistance points author iz ed b y us;

b) or if GENUINE SP ARE P AR TS are not used to replace

par ts;

c) or if the indications and pro visions giv en in the instr uc-

tions handbook are not complied with.

The same pro visions hold f or the accessor ies .

Resistance

The maxim um temper ature of the deliv er y liquid should

ne v er e xceed +35 ° C in contin uous oper ation.

Infiammab le , comb ustib le or e xplosive liquids cannot

be con ve y ed with this pump!

In par ticular , do not use engine fuels , de tergents , o r o ther

chemical products .

2. Use

CA UTION! Sector of use

“DRAINA GE” – To tr ansf er and empty fresh to

slightly polluted w ater from r ainw ater barrels and

casks .

“V OR TEX” – Po r tab le submersib le pump f or

discharge and w aste w ater with solids in suspen-

sion.

Also used as emergency pump , in case of o v er-

flo wing with m uddy w ater , t hanks to its large

suction filter .

To ac hie ve e xcellent motor cooling the pump

casing is pr o vided with a breather hole that enab les

water to flo w out.

The pump m ust be pr otected fr om running dr y .

Star ting

First put the pump into w ater and then

connect the plug.

The pump is ready f or use .

3. Bef ore star ting

Installation of y our canned motor pump is:

• fix ed with a fixd pipe , or

• fix ed with a fle xib le hose .

T ake care

When installing it is necessar y to tak e care that the pump

is ne v er fitted hanging from its deliv er y pipe , b ut is alw a ys

placed in a r aised position with respect to the bottom of

the well so that the muddy bottom is

the water

Nev

supply cable

In pumps

order to make immediate starting possibile.

Note

The pump well must hav minimum dimensions of

40x40x50 cm.

It

wells with an inner diameter of appro

4.

Your canned motor

maintenance.

checks

Howe

we recommend constant care and regular checks.

•Before e

•For tr

clear water after e

•For

operation of the floating s

•Using

par

•In the

dismantle the inlet filter by

W

•Every 3 months remo

walls of the well.

•Eliminate the

it with fresh water

•Protect the pump from frost.

CA

“DRAINA

Special

sewage,

The pump must ne

The

the

running dry

“V

The pump must ne

The

the

running dry

CA

The motor will not work

The motor

Insufficient flow rate

Repeated switching off with disconnection of the protection s

TROUBLE

No mains voltage

Defectiv

Motor protection disconnected, pump straining/bloc

Dry operation protection disconnected, the water lev

Defectiv

Clogged suction opening

Check v

Delivery pipe clogged

Foreign bodies in the pump

The pump runs dr

If it is not possibile to eliminate the trouble,

To avoid damage during transport,

Troubleshooting

ENGLISH (Original instructions)

SubmErSIbLE pump