T

I

S

I

U

B

A

P

U

I

I

C

4

3

D

2

I

E

V

U

1

F

15

3-INSTALLATION

Technical Dept. - All rights reserved - Reproduction is prohibited

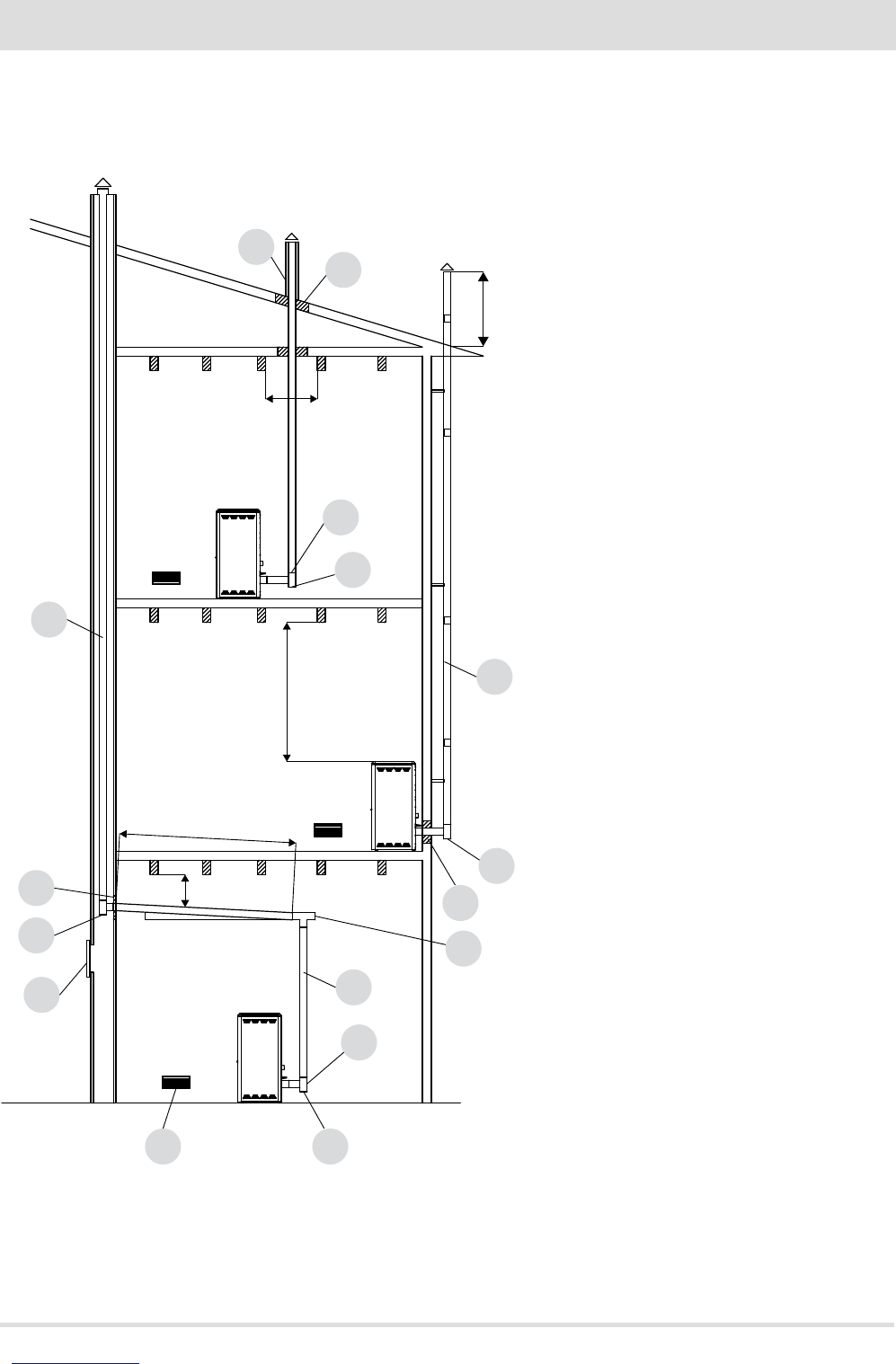

EXAMPLES OF CORRECT INSTALLATION

1. Installation of Ø120mm ue with hole for the passage

of the pipe increased by:

minimum 100 mm around the tube if next to non

ammable parts such as cement, brick, etc.; or

minimum 300mm around the pipe (or as required by

data tags) if next to ammable parts such as wood etc.

In both cases, install suitable insulation between the

ue and the ceiling.

Always check and respect the data tags on the ue,

in particular the minimum safety distances from

combustible materials.

The previous rules also apply for holes made in walls.

2. Old ue, minimum pipe Ø100mm with the inclusion

of an external access door for chimney cleaning.

3. External ue made of insulated stainless steel pipes,

i.e. with double walls minimum Ø100mm: all securely

mounted on the wall. With wind-proof chimney cap. See

g. 7 type A.

4. Ducting system using T tting that allows easy access

for cleaning without having to remove the pipes

FIGURE 11

U = INSULATING

V = ANY REDUCTION FROM 100 TO 80 MM

I = INSPECTION CAP

S = INSPECTION ACCESS PANEL

P = AIR INLET

T = T JOINT WITH INSPECTION CAP

A = MINIMUM 40 MM

B = MAXIMUM 4 M

C = MINIMUM 3°

D = MINIMUM 400 MM

E = HOLE DIAMETER

F = SEE FIG.2-3-4-5-6