POWXG3041 EN

Copyright © 2018 VARO P a g e | 8 www.varo.com

8.4.3 Installation of the cutting section of the machine (Fig. 5A)

▪ Pull the locking pin (1) out and turn it left and right to unlock it. Then push the cutting

section of the machine (2) inwards and release the locking pin (1). Make sure that it is

secured in the hole (3) of the drive shaft. This is easier to do if you slightly rotate the tip of

the drive shaft (2) in both directions. The locking pin (1) is in place when it is fully inserted

in the hole.

▪ Finally, tighten the knob (4).

9 FUEL AND LUBRICATION

9.1 Fuel

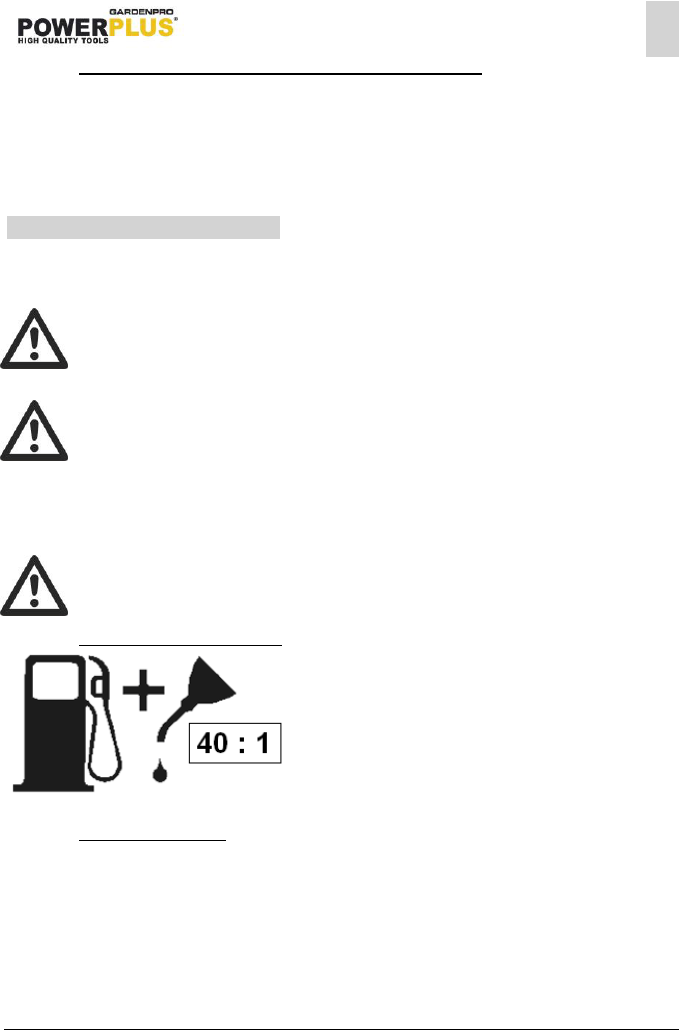

Use regular grade unleaded petrol mixed with 40:1 custom 2-cycle engine oil for best results.

WARNING: Never use normal petrol in your unit. This will cause permanent

engine damage and void the manufacturer’s warranty for the product. Never

use a fuel mixture that has been stored for over 90 days.

WARNING: 2-cycle lubricant must be a premium grade oil for 2-cycle air

cooled engines mixed at a 40:1 ratio. Do not use any 2-cycle oil product with a

recommended mixing ratio of 100:1. If insufficient lubrication is the cause of

engine damage, it voids the manufacturer’s engine warranty.

9.2 Mixing fuel

Add oil to an approved fuel container followed by the petrol to allow incoming petrol to mix with

oil. Shake container to ensure thorough mix.

WARNING: Lack of lubrication voids engine warranty. Petrol and oil must be

mixed at 40:1.

9.2.1 Fuel and lubrication symbols

9.2.2 Recommended fuels

Some conventional kinds of petrol are now blended with oxygenates such as alcohol or an

ether compound to meet clean air standards. The engine is designed to operate satisfactorily

with any petrol intended for automotive use including oxygenated petrol.