6

TIME RANGE VALUE

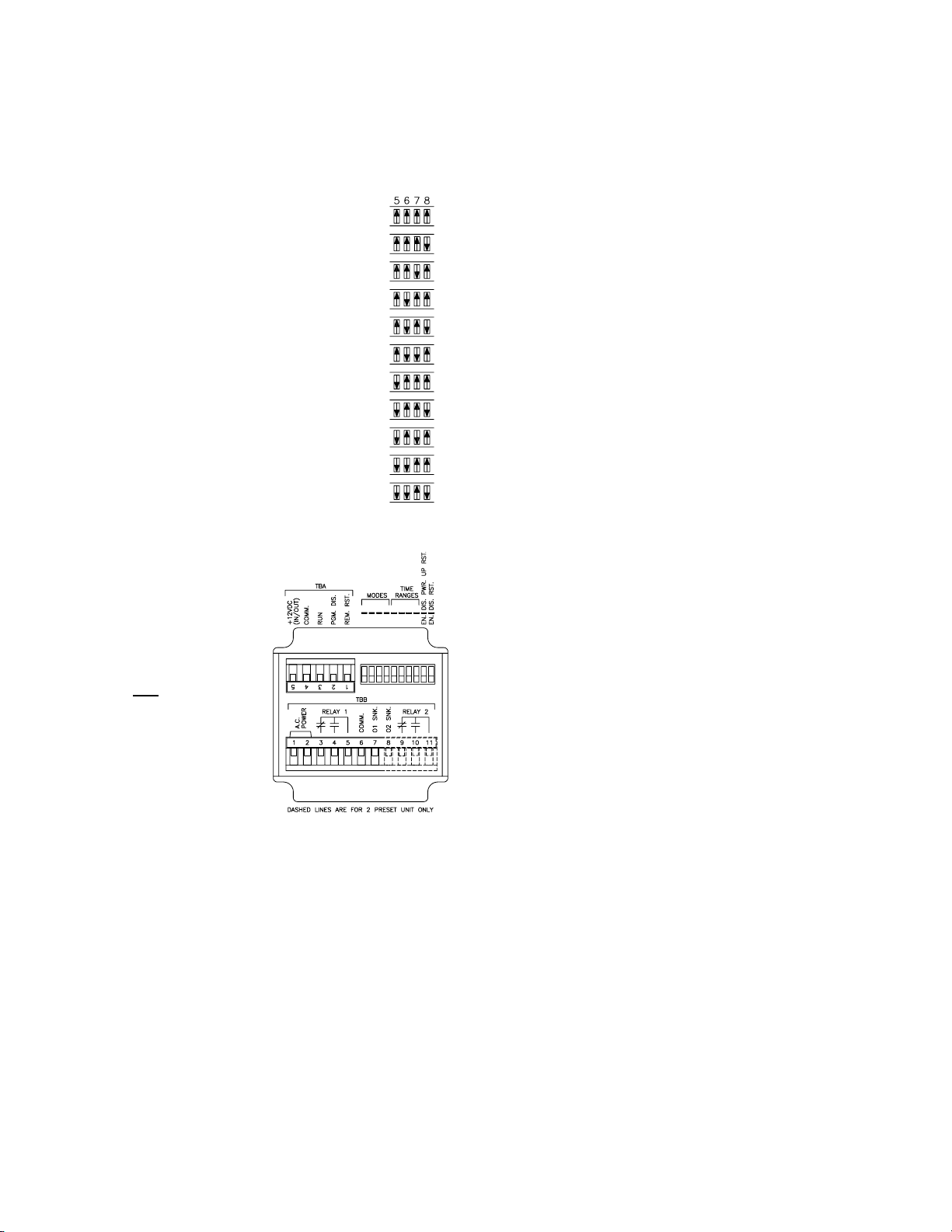

Time Range switch settings are shown to the right of the chart below. The

time range number corresponds to a binary code represented by the DIP switch

positions. When the switch is up, it is equivalent to a zero. When the switch is

down, it is equivalent to a one. The time range switch settings can be easily

observed from the front panel by using self-test. At the end of self-test (the third

set of switches shown), the state of these time range switches are displayed.

These time range values must not be changed during normal course of operation

because of the possibility of erratic operation. A reset must be made after the

desired range has been selected to lock it into the internal memory.

TIME RANGE ZERO 99.99 Seconds

TIME RANGE ONE 99.99 Minutes

TIME RANGE TWO 99.99 Hours

TIME RANGE FOUR 999.9 Seconds

TIME RANGE FIVE 999.9 Minutes

TIME RANGE SIX 999.9 Hours

TIME RANGE EIGHT 9999 Seconds

TIME RANGE NINE 9999 Minutes

TIME RANGE TEN 9999 Hours

TIME RANGE TWELVE 99 Minutes and 59 Seconds

TIME RANGE THIRTEEN 99 Hours and 59 Minutes

Note: TIME RANGES 3, 7, and 11 are not valid ranges.

CONNECTIONS

As depicted in the drawing showing

the rear view of the Libra Timer, there

are two terminal blocks where all

wiring connections are made. The

blocks can be removed for easy access

to the terminal screws. To remove the

block, pull from the back of the block

until it slides clear of the terminal block

shroud. CAUTION: The terminal

blocks should NOT be removed with

power applied to the unit.

All the DC power and input

connections are made to the top

terminal block labeled TBA. The AC

power and output connections are

made to the bottom terminal block

labeled TBB. The input connections

will be discussed first, using the

drawing as a guide.

(The input connections are the same for 1 or 2 preset timers.)

EMC INSTALLATION GUIDELINES

Although this unit is designed with a high degree of immunity to

ElectroMagnetic Interference (EMI), proper installation and wiring methods

must be followed to ensure compatibility in each application. The type of the

electrical noise, source or coupling method into the unit may be different for

various installations. It should be noted that the methods listed below may not

be necessary for every unit installation. In extremely high EMI environments,

additional measures may be needed. The unit becomes more immune to EMI

with fewer I/O connections. Cable length, routing and shield termination are

very important and can mean the difference between a successful installation or

a troublesome installation. Listed below are some EMC guidelines for

successful installation in an industrial environment.

1. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in

order of their effectiveness.

a. Connect the shield only at the panel where the unit is mounted to earth

ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the unit and leave the other end of the

shield unconnected and insulated from earth ground.

2. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run in metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter.

3. Signal or Control cables within an enclosure should be routed as far away as

possible from contactors, control relays, transformers, and other noisy

components.

4. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional protection.

Install line filters on the power input cable to the unit to suppress power line

interference. Install them near the power entry point of the enclosure. The

following EMI suppression devices (or equivalent) are recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC #FCOR0000)

TDK # ZCAT3035-1330A

Steward #28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC #LFIL0000)

Schaffner # FN670-1.8/07

Corcom #1VB3

Corcom #1VR3

Note: Reference manufacturer’s instructions when installing a line filter.

5. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

6. Switching of inductive loads produces high EMI. Use of snubbers across

inductive loads suppresses EMI.

Snubbers:

RLC #SNUB0000

DC POWER AND INPUT CONNECTIONS

Terminal number 5 on TBA (the first terminal from the left), is the +12 VDC

input/output terminal. As an output, this terminal is for sensor supply and can

provide up to 150 mA of current. As an input, an external 11 to 14 VDC supply

can be applied to this terminal to power the unit in the absence of AC power.

Terminal 4 is the common terminal which the common line from the sensor and

other inputs are connected. (Do NOT connect relay common or solid-state output

common to this point.) Terminal 3 is the run terminal. When the signal at this

terminal is pulled low (zero volts), time will accumulate on the display. Terminal

2 is the Program Disable (PGM. DIS.) terminal. When this terminal is at high

level (+5 V), the Preset value (s) and timed output value(s) can be changed using

the front panel buttons. (Outputs can also be tested during self-test. See “Self-

Test” section for further details.) When terminal 2 is at a low level (connected to

COMMON), changing these values and testing of the outputs is no longer

possible. Terminal 1 is the Remote Reset terminal. When this terminal is at a low

level (connected to COMMON), the unit will reset and, the outputs will turn off

(if activated). As long as reset is low, the unit is held at reset.

Do not power up the unit with the Remote Reset terminal tied low and the

Power Up Reset DIP switch enabled. This causes the display to lock. To restore

the display, move the DIP switch to the disable position and cycle power.

AC POWER & OUTPUT CONNECTIONS

As mentioned before, AC power and output connections are made to the

bottom terminal block, labeled TBB. Primary A.C. power is connected to

terminal 1 and 2 (marked A.C. Power, located on the left-hand side of terminal

block TBB). For best results, the A.C. Power should be relatively “clean” and

within the specified ±10% variation limits. Drawing power from heavily

loaded circuits or from circuits that also power loads that cycle on and off,

should be avoided.

Terminals 3, 4, and 5 are used to connect to the output relay 1. Terminal 3 is

the normally closed contact. Terminal 4 is the normally open contact, and

Terminal 5 is the output relay common. Terminal 6 is an output common used

for the solid-state output(s). This terminal should NOT be used as the common

for the input or control terminals. Terminal 7 is the current sinking output 1

(labeled 01-SNK.). This internally connects to an NPN Open Collector

transistor. The remaining terminals are for the dual preset version of the Libra

timer and serve the same functions as those for the single preset unit. Terminal

8 is current sinking output 2 (labeled 02-SNK.). Terminal 9 is the normally

closed contact of relay 2. Terminal 10 is the normally open contact. Terminal 11

is the output relay common.