Maximum displacement of the movable front

panel over the centre of the blade tool is 45 mm.

(Fig. 15 and 16).

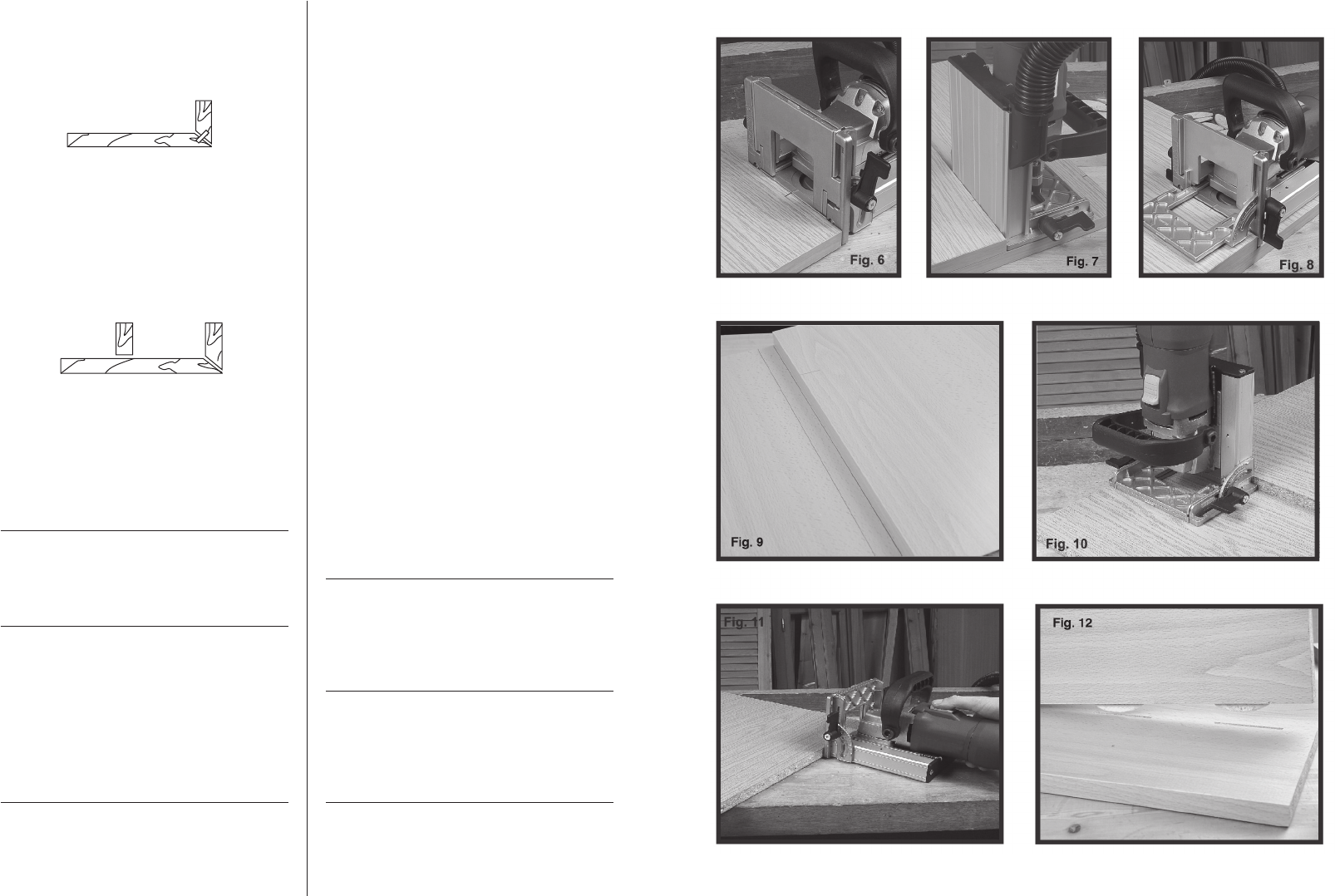

8.3 MITRE JOINTING

For all board thicknesses and angle, use the

movable front panel and the movable fence (Fig.

18 and 19). Example: 45° MITRE JOINT. Position

the front movable panel at the desired distance

and the movable fence at 45° (Fig. 20 and 21).

Glue and assemble (Fig. 22).

8.4 FRAME JOINTING

Frames can be mitre or square jointed. Two spli-

nes are recommended if the thickness is greater

than 25 mm. (Fig. 23, 24, 25).

8.5 LENGTHWISE JOINTING

For lengthwise jointing, the movable front panel

should be set at board thickness. Proceed as

indicated in figures (Fig. 26, 27, 28).

9. STARTING UP THE MACHINE

To start up the machine, push button R forward

(Fig. 14) to the on position.

To stop the machine, simply press the back of the

switch and it will return to the off position.

10. CHANGING THE DISC

WARNING! Unplug the machine from the electri-

cal outlet before any maintenance operations.

Remove the cover A fixing bolts (Fig. 29).

Separate the base from the machine body (Fig.

30).

Remove the disc with the wrench, as shown in

(Fig. 31).

Clean the seat and follow the instructions for

assembly in reverse order (Fig. 32).

11. DEPTH ADJUSTEMENT

WARNING! Unplug the machine from the electri-

cal outlet before any maintenance operations.

Put the depth regulator in the nº 20 position and

set the disc outlet at 12 mm with the nuts, main-

taining the machine in the cutting position (Fig.

33 and 34).

To check the depth, cut a groove, insert a piece

of board and mark with a pencil. Turn it over and

check that the mark coincides. If not, correct the

defect by adjusting the nuts. (Fig. 35).

Recommendations:

Keep the machine clean and lubricate the guides

periodically. They should never be left dry (Fig.

36 and 37).

12. MAINTENANCE OF BRUSHES

AND COLLECTOR

WARNING! Unplug the machine from the electri-

cal outlet before any maintenance operations.

Remove screws B (Fig. 384) that fasten the side

covers and detach both.

Remove the brush-holder H (Fig. 39) with small

screwdriver G, using one of the brush-holder side

tabs to lever it out.

Push back the end of spring C.

Keep it in this position to extract the brush and

replace it with a new genuine Rupes brush.

Reinsert the brush-holder, ensuring that it is fir-

mly positioned in the casing and that each of the

brushes exerts a small amount of pressure on

the collector.

Re-attach the covers F with the corresponding

screws, making sure that no wires get caught in

the process.

It is advisable to leave the machine running for

15 minutes once the brushes have been chan-

ged.

If the collector burns or juts out, it should be ser-

viced by a Rupes service technician. Keep the

lead and plug in good working condition.

13. MOUNTING INSTRUCTIONS

SUCTION NOZZLE

Remove the cover E bolt D (Fig. 40). Introduce

the nozzle through the guides up to its limit (Fig.

41). Replace the bolt D, pressing the nozzle

against the cover (Fig. 42).

14. NOISE LEVEL AND VIBRATIONS

These levels have been measured according to

the European Standard EN50144.

Noise level at work area can exceed 85 dB (A). I

n that case operators should protectthemselves

against damage to hearing.

15. WARRANTY

All RUPES power tools are guaranteed for 12

months from the date of purchase, excluding any

damage which is a result of incorrect use or of

natural and tear on the machine. All repairs

6