45

12. REFRIGERANT R410A:

SPECIAL PRECAUTIONS WHEN SERVICING UNIT

12-1. Characteristics of New Refrigerant R410A

12-1-1. What is New Refrigerant R410A?

R410A is a new refrigerant that contains two types of pseudo-non-azeotropic refrigerant mixture. Its

refrigeration capacity and energy efficiency are about the same level as the conventional refrigerant, R22.

12-1-2. Components (mixing proportions)

HFC32 (50%) / HFC125 (50%)

12-1-3. Characteristics

●

Less toxic, more chemically stable refrigerant

●

The composition of refrigerant R410A changes whether it is in a gaseous phase or liquid phase. Thus, when

there is a refrigerant leak the basic performance of the air conditioner may be degraded because of a change

in composition of the remaining refrigerant.

Therefore, do not add new refrigerant.

Instead, recover the

remaining refrigerant with the refrigerant recovery unit. Then, after evacuation, totally recharge the specified

amount of refrigerant with the new refrigerant at its normal mixed composition state (in liquid phase).

●

When refrigerant R410A is used, the composition will differ depending on whether it is in gaseous or liquid

phase, and the basic performance of the air conditioner will be degraded if it is charged while the refrigerant is

in gaseous state.

Thus, always charge the refrigerant while it is in liquid phase.

12-2. Checklist Before Servicing

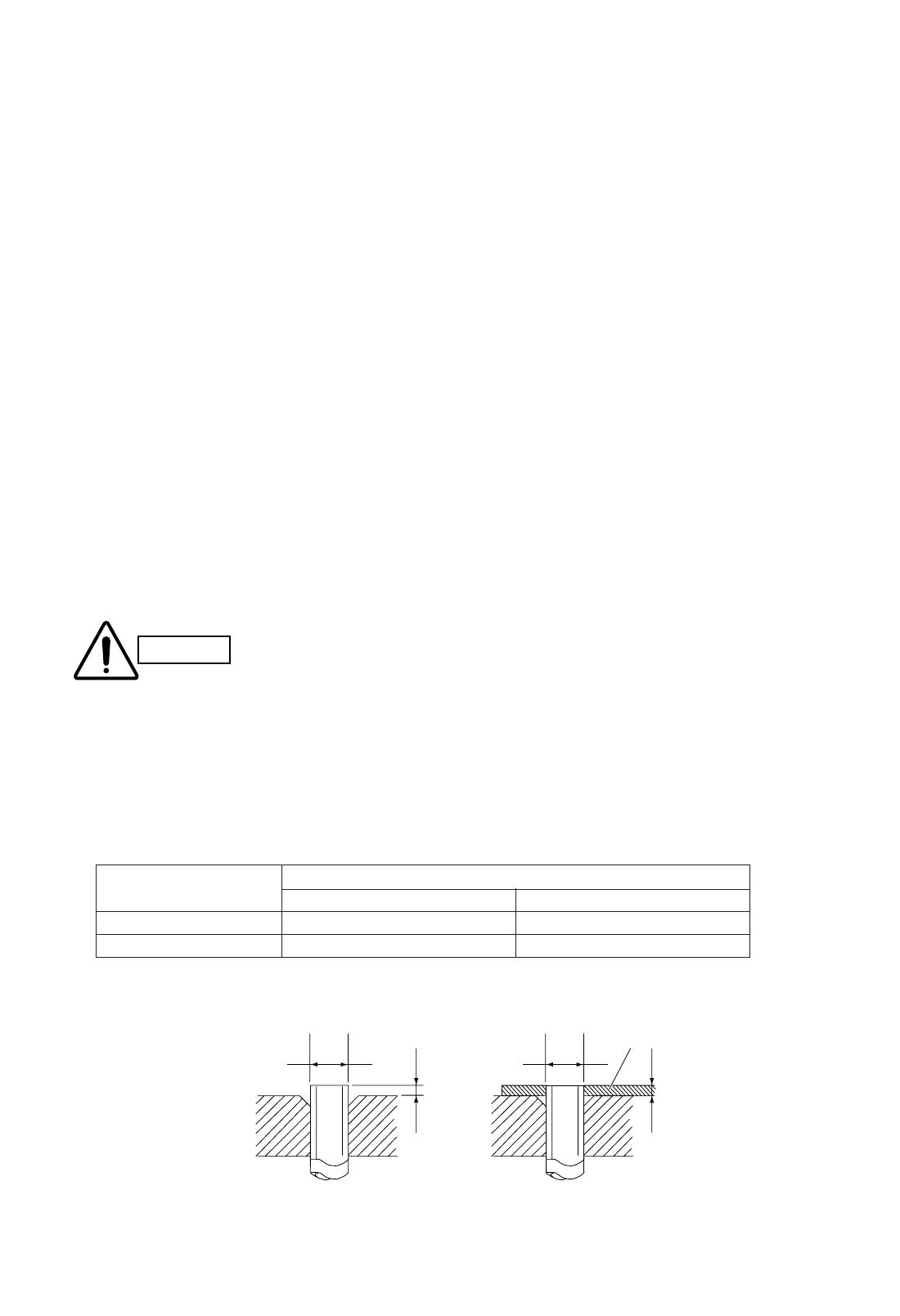

Use a clutch-type flare tool for R410A or the conventional flare tool. Note that sizes of the resultant flares differ

between these two tools. Where a conventional flare tool is used, make sure to observe A Specification (amount

of extrusion) by using the flare spacer.

●

Size of flare

Ether-type oil is used for compressor oil for R410A-type units, which is different

from the mineral oil used for R22. Thus more attention to moisture prevention and

faster replacement work compared with conventional models are required.

Diameter of tube (ø) D

A Specification

Flare tool for R410A Conventional flare tool (for R22)

ø6.35 (1/4") 0 – 0.5 mm 1.0 – 1.5 mm

ø9.52 (3/8") 0 – 0.5 mm 1.0 – 1.5 mm