50

12-6. In Case Refrigerant is Leaking

(1) Detecting Leaks

● Use the detector for R410A to locate refrigerant leak

points.

(2) Recovering refrigerant

● Never release the gas to the atmosphere; recover

residual refrigerant using the refrigerant recovery unit

for R410A, instead.

● Do not reuse the recovered refrigerant because its

composition will have been altered.

(3) Welding leaking points

● Confirm again that no residual refrigerant exists in the

unit before starting welding.

● Weld securely using flux and wax for R410A.

● Prevent oxide film from forming inside the tubes utiliz-

ing substitution with nitrogen (N2) in the refrigerant

circuit of the unit. Leave ends of tubes open during

welding.

(4) Checking for sealing

● Use nitrogen gas for the pressurized gas, and never

use a refrigerant other than R410A. Also do not use

oxygen or any flammable gas.

(5) Evacuation

●

Use a solenoid valve-installed vacuum pump

so

that even if power is cut off in the middle of evacuation

of air due to a power interruption, the valve will prevent

the pump oil from flowing back.

● The equipment may be damaged if moisture remains

in the tubing, thus carry out the evacuation thoroughly.

● When using a vacuum pump with exhaust air volume

more than 25L/min. and ultimate vacuum pressure rate

of 0.05Torr:

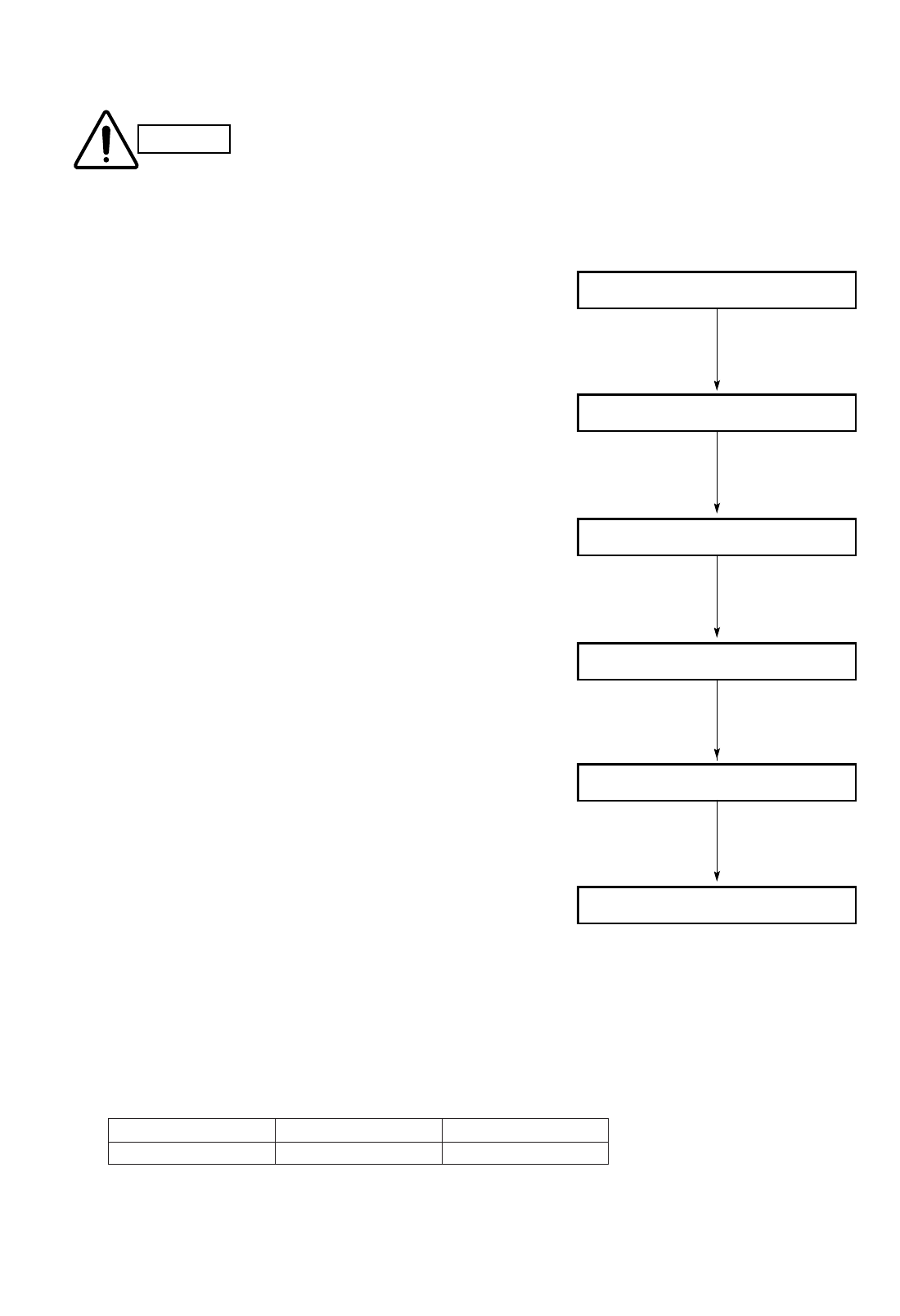

Standard time for evacuation

(6) Recharging

● Recharge unit in the same manner explained on the

previous page “(5) Recharging.”