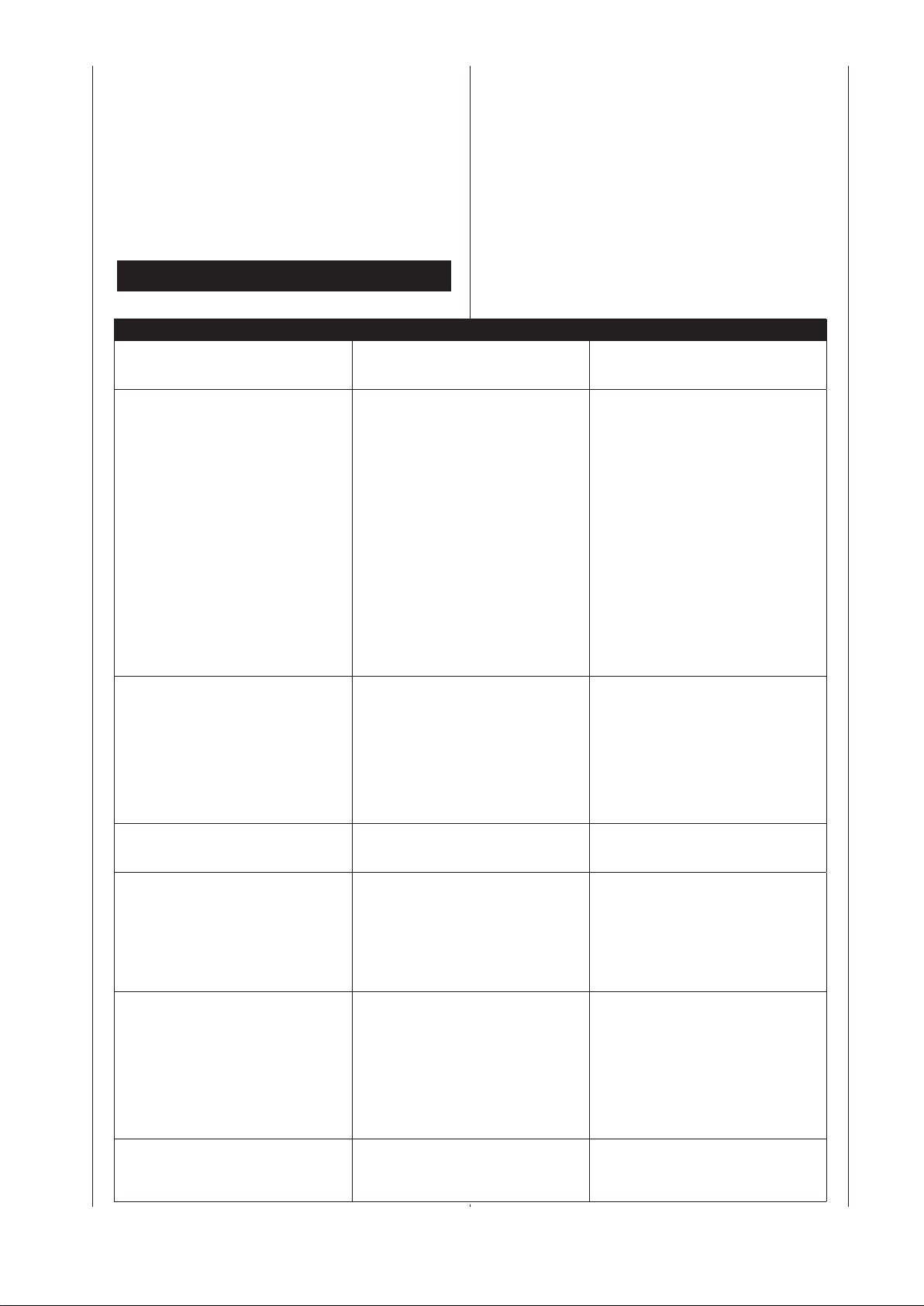

14 english

Malfunction Possible cause Solution

1.

Brake motor has no brake function

a)

Brake pads are worn

Have brake pads renewed.

Electrical connection works only by a

specialized electronics technician!

2.

Saw blade detaches after switching off the

motor.

a)

Attachment nuts are not tightened enough

b)

Brake effect of motor is too strong

a)

Tighten attachment nuts M20 left-hand

thread

b)

Adjust electric current brakes

•

Take out little plug sideways from switch

housing

•

Use small screw driver to adjust carefully

the electric current of the brakes on the

potentiometer

•

After switching off the motor the saw blade

stagnation should take place after 8 - 19

seconds

•

Put the little plug into the switch housing

again

3.

Motor does not initiate

a)

Breakdown mains fuse

b) Extension cable defect

c)

Connections to the motor or to the switch

are not in order

d)

Motor or switch is defect

t

a)

Check mains fuse

b)

See instructions “Electrical connections“

c)

Have it checked by an electronics

technician

d)

See instructions “Electrical connections“

4.

Motor runs backwards or forwards

Condensator defect Have it exchanged by an electronics

technician

5.

Motor does not perform, switches off

automatically

Overcharged because of

a)

Blunt saw blade

b) 2 Phase run – Motor becomes hot

a)

Put in a sharpened saw blade

b)

Have the extension cable and the main

power supply checked by a specialized

electronics technician

6.

Burn marks on the intersection

by longitudinal cuts

by cross cuts

a)

Blunt saw blade

b)

Wrong saw blade

c)

Longitudinal end stop not parallel to saw

blade

d)

Slide table not parallel to saw blade

a)

Put in a sharpened saw blade

b)

Put in a saw blade for longitudinal cuts

c)

Re-adjust motor on rocker or exchange

longitudinal end stop

d)

Align slide table to saw blade

7.

Wrong rolling direction by rotary current

motor

Socket wrongly tapped Change polarity of socket

TROUBLESHOOTING PLAN