12 english

Possible causes are:

window or door gaps.

the connection cable.

of the wall socket.

Such defective electrical connection cables must not be

used as the insulation damage makes them extremely haz-

ardous.

Check electrical connection cables regularly for damage.

Make sure the cable is disconnected from the mains when

checking.

Electrical connection cables must comply with the regula-

tions applicable in your country.

Single-phase motor

-

fied on the motor’s rating plate.

cross-section of 1.5 mm2, and beyond 25 m at least 2.5

mm2.

16 A slow-acting fuse.

Only a qualified electrician is permitted to connect the ma-

chine and complete repairs on its electrical equipment.

In the event of enquiries please specify the following da-

ta:

If a motor has to be returned, it must always be dispatched

with the complete driving unit and switch.

Maintenance

elimination of any malfunctions must only be undertak-

en after turning off the motor.

immediately upon completion of any repair or mainte-

nance work.

when changing tools.

by unscrewing it, cleaned and then sprayed with a dry

lubricant. Grease the threaded spindle.

tool holder and adjust if necessary. In addition, tighten

the hex nut under the bracket.

Accessories

Article Art. No.

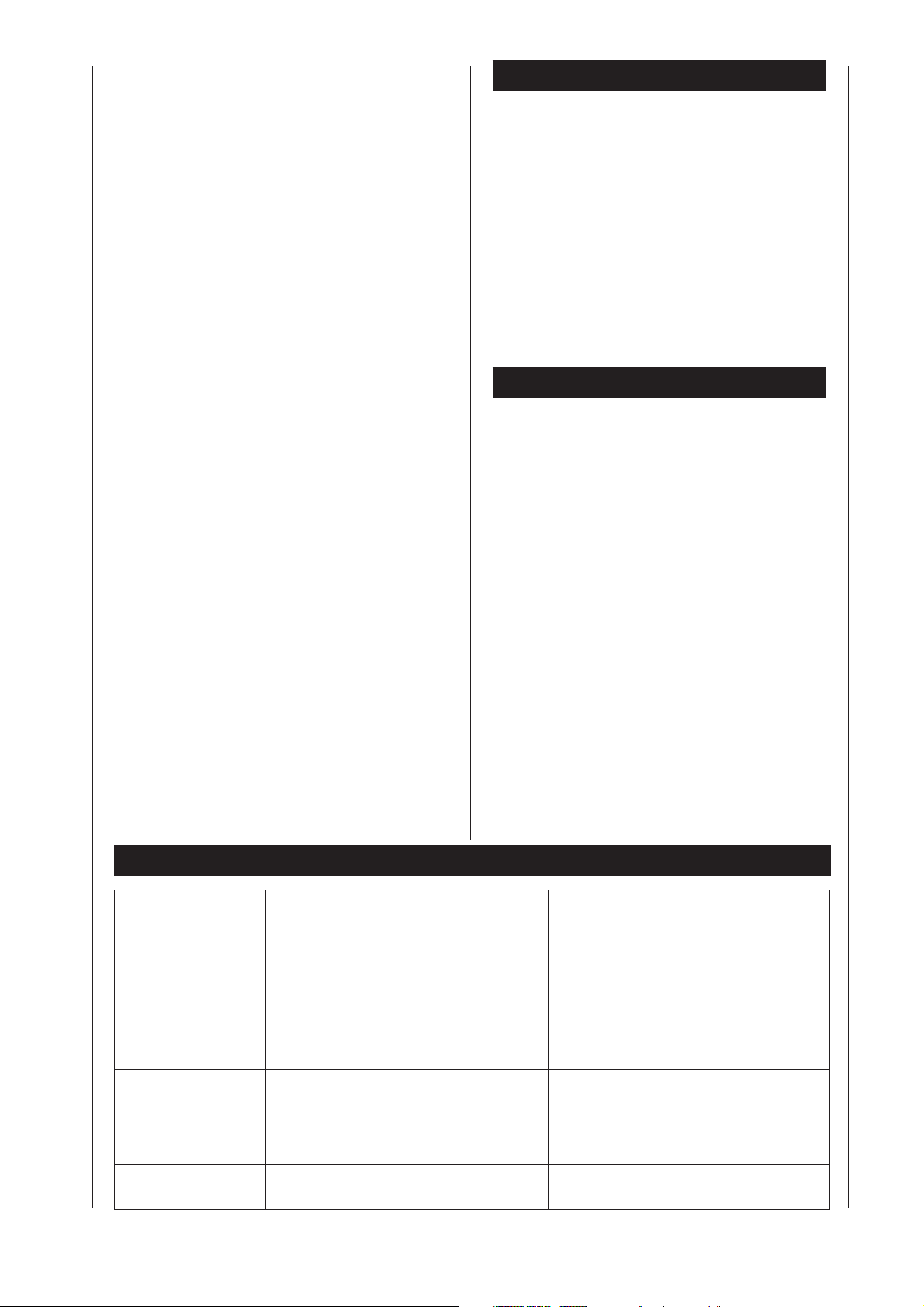

Trouble shooting

Problem Possible Cause Help

Motor doesn’t start b) Defective switch, condenser

c) Defective extension cord

a) Check fuse

b) Have an electrician inspect unit

necessary

Drilled holes become

larger than the drill bit

Headstock and tailstock are not parallel. Set up headstock according to the tailstock

tip. Insert carrier into the drilling spindle for

this and position the tailstock with tip up to a

Work piece flatters

while working

a) Working piece becomes loose

while working

b) Work piece is not properly centered

a) Follow the instructions in the operating

manual

b) Follow the instructions in the operating

manual

c) Select a lower rotational speed

Tool rest or tailstock

cannot be clamped

Setting the eccentric clamping