english 17

Additional Safety Information

for the Propeller Shaft Operation

• For tractors with a hydraulically or pneumatically con-

trolled power take-off clutch, a free-wheeling propeller

shaft is to be used.

• Stop the machine, turn off the tractor, and remove the

ignition key before you repair failures or remove pinched

pieces of wood.

• If you leave the workplace, turn off the tractor and

remove the ignition key.

• During a transport of the circular saw, the power take-off

operation must be turned off.

• The warning sign with rear light according to

DIN 110030 must be mounted on the saw, and the rear

light must be connected to the tractor.

• The circular saw may only be operated with tractors with

a 3-point-attachment (category 1 and 2) at an engine

speed of 1/min. 540.

Setup and Adjustment of the Machine

• Only perform retooling, measuring, and cleaning work

when the motor is turned off. Disconnect the mains

plug, and wait until the rotating tool stands still.

• All protection and safety devices must be immediately

reinstalled once the repair and maintenance work is

completed.

• Only use saw blades that are well-sharpened, free of

cracks and do not show any deformation.

Intended Use

• The circular saw has been exclusively designed for the

processing of wood using the tools provided.

• The machine meets the currently valid EU machine

directive.

• The machine has been designed for a one-shift

operation, operating factor S6-40%.

• Independent of the wood diameter, only 1 piece may be

put on the rocker/the table.

• Observe all safety instructions and warnings on the

device.

• Make sure that all safety instructions and warnings on

the machine always are in a readable state.

• If the machine is used in closed rooms, it must be

connected to an exhaust system.

• Only use the machine if it is in a technically faultless

state. Pay attention to the intended use, the safety and

dangers and comply with the operating instructions!

Immediately repair (or have repair) failures which may

affect the safety!

• The safety, working, and maintenance instructions and

the dimensions set forth in the specifications must be

observed.

• The applicable regulations for the prevention of

accidents and other, generally recognized safety rules

must be observed.

• The machine may only be used, maintained or

repaired by trained persons who are familiar with the

machine and have been informed about the dangers.

Unauthorized modifications of the machine exclude a

liability of the manufacturer for damages resulting from

the modifications.

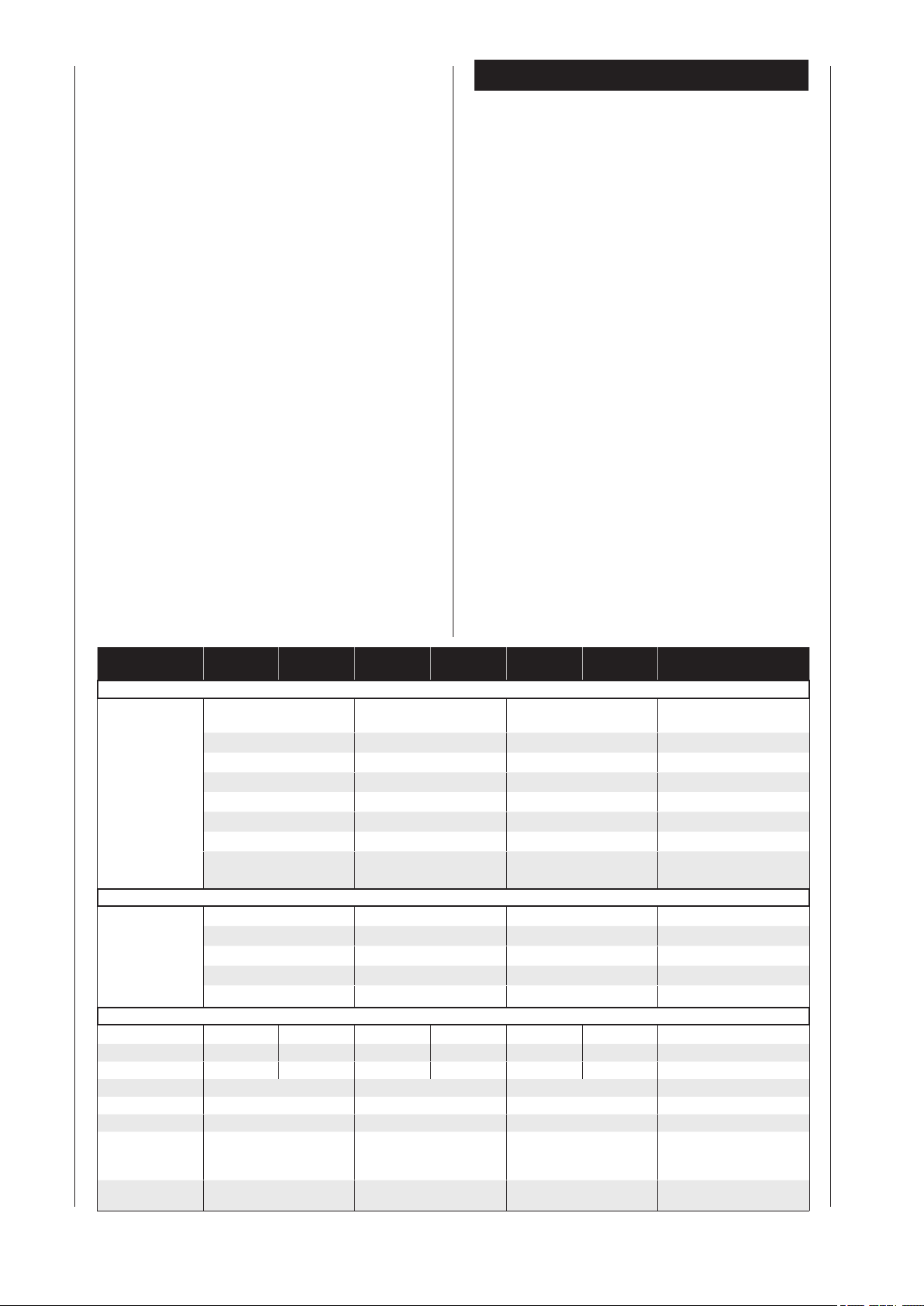

KW 7 KWZ 7 KW 70m KWZ 700 KE 70m KEZ 700 KE d 700

Scope of delivery

Rocking frame

circular saw

Rocking table

circular saw Sliding table circular saw Sliding table circular saw

Single-head wrench Single-head wrench Single-head wrench Open-end wrench

Locking pin Locking pin Locking pin Locking pin

Operating instructions Operating instructions Operating instructions Operating instructions

Moving device Longitudinal limit stop Moving device

Sliding stick

Sliding handle

Covering cap for ripping

cuts

Special accessories

various saw blades various saw blades various saw blades Ripping cut device

Transport device Moving device Moving device various saw blades

Peeling device Peeling device Peeling device

Propeller shaft Propeller shaft Propeller shaft

Ripping cut device

Structural dimensions

Overall length in mm 820 960 850 950 860 960 1,270

Overall width in mm 1,060 1,410 1,400 1,650 1,460 1,550 730

Overall height in mm 1,150 1,150 1,250 1,250 1,210 1,210 1,130

Rocker support mm 720 700 – 655

Table size mm – 1,260 x 850 1,400 x 860 1,400 x 860

Table height mm – 850 850 850

Saw blade ø

ripping cuts

max. mm

700 700 700 700

Idle-running speed

saw shaft 1/min. 1,400 1,400 1,400 1,400