21GB

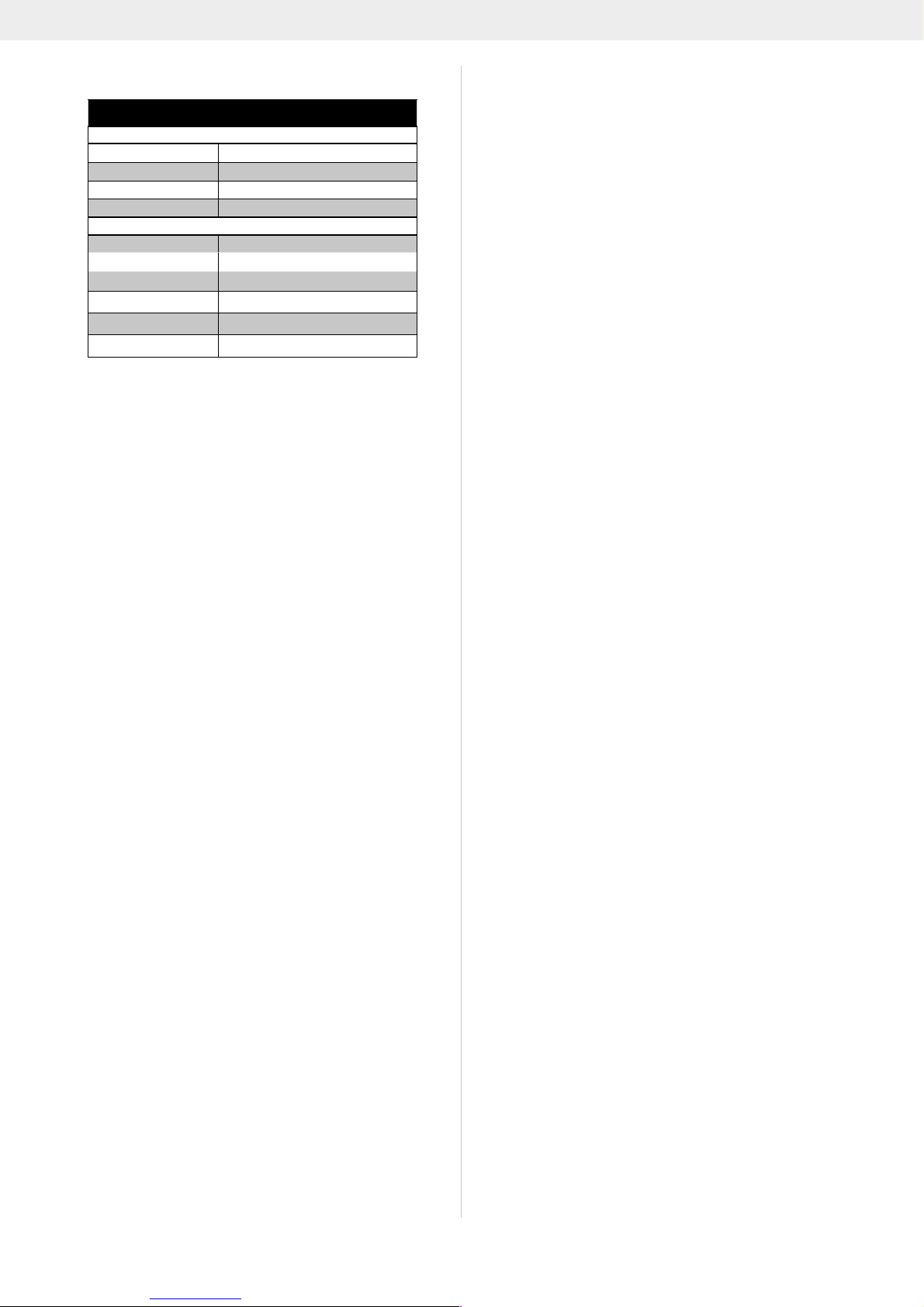

6. Technical data

LB5200BP

Technical data

Dimension LxWxH mm 1380x400x450

Air speed max. km/h 295

air volume max. m3/min 18

dust bag capacity l -

Power unit

Displacement cm351,7

Max. engine output kW 1,4

Idle speed min-1 3500 ± 300

Fuel tank capicity cm31000

Engine type 2-stroke engine, air-cooled

Weight kg 7,84

Subject to technical changes!

Information concerning noise emission measured

according to relevant standards:

Sound pressure LpA = 94,0 dB(A)

Sound power LWA = 110 dB(A)

Uncertainty KPA = 3 dB(A)

Wear ear-muffs.

The impact of noise can cause damage to hearing.

Vibration Ahv = 1,655 m/s2

Uncertainty KPA = 1.5 m/s2

Reduce noise generation and vibration to a minimum!

• Use only equipment that is in perfect condition.

• Maintain and clean the equipment regularly.

• Adopt your way of working to the equipment.

• Do not overload the equipment.

• Have the equipment checked if necessary.

• Switch off the equipment when not in use.

• Wear gloves.

In these operating instructions we have marked the

places that have to do with your safety with this sign:

7. Attachment and operation

ATTENTION! Before working on the device - cleaning,

inspection, maintenance or other work - always turn off

the device.

ASSEMBLY

The blower must not be used or switched on until

it has been fully assembled.

Assembly (Fig6-6c)

• Attach the two hose clamps (17A and 17B) to the e-

xible blowpipe (12).

• Push the exible blowpipe (12) over the connection to

the motor unit and tighten the hose clamp (17B) rmly

(Fig. 6).

• Now push the handle (1) over the upper blowpipe (13).

Align the handgrip (1) and the guide in the same way,

fold it together and then tighten it (Fig. 6a).

• Push the upper blowpipe into the exible blow hose

(12) with the handle and x it with the hose clamp (17A)

(Fig. 6b).

• Push the lower blowpipe (14) over the upper blowpipe

(13) and lock it in the clockwise direction (Fig. 6c)

• The blower nozzle (No. 15) is simply pushed over the

lower blowpipe (No. 14) and locked in the clockwise di-

rection (Fig. 6c).

Warning! Use only original manufacturer‘s replace-

ment parts, accessories and attachments. Failure to

do so can cause poor performance, possible injury and

may void your warranty. Never use the machine wit-

hout the guard assembled!

Operation

Before starting

Each time before use, check the following:

• That there are no leaks in the fuel system.

• That the equipment is in perfect condition and that the

safety devices and cutting devices are complete.

• That all screws are securely fastened.

• That all moving parts move smoothly.

Place the carrying strap

Pull the belt down, the straps are tightened

Loosen the straps

Lift the clamping slide

Adjust the carrying strap so that the back plate rests rm-

ly and securely against t

Fuel and oil

Recommended fuels

Use only a mixture of unleaded petrol and special 2-stro-

ke engine oil. Mix the fuel mixture as indicated in the fuel

mixing table.

Important: Do not use a fuel mixture which has been

stored for longer than 90 days.

Important: Never use 2-stroke oil with a recommended

mixing ratio of 100:1. The manufacturer’s warranty

will be voided in case of engine damage due to inade-

quate lubrication.

Important: Only use containers designed and approved

for the purpose to transport and store fuel.

Pour the correct quantities of petrol and 2-stroke oil into

the mixing bottle (see scale printed on the bottle). Then

shake the bottle well.

Never use oil for 4-cycle engine or use water cooled

2-cycle engine. It can cause spark plug fouling exhaust

part blocking or piston ring sticking.

Mixed fuels, which have been left unused for a period of

one month or more, may clog the carburetor or result in

the engine foiling to operate property. Put remained fuel

into an airtight container and keep it in the dark and cool

room.