-11-

USING THE LASER LINE GUIDE

Your tool is equipped with a laser line guide

that will turn on whenever the tool is plugged

in and the laser button is pushed in (Fig. 1).

The laser line is pre-set at the factory to the

kerf of the blade supplied with your saw.

If using the laser line guide for cutting you do

not need the line guide incorporated in the

foot as it may be in a different setting than the

laser line guide.

The laser light guide is a class IIIA laser with a

maximum output power of 5.0 mWatts and

conforms to 21 CFR 1040.10 and 1040.11.

LASER RADIATION.

AVOID DIRECT EYE

EXPOSURE. DO NOT stare into the laser

light source. Never aim light at another

person or object other than the workpiece.

Laser light can damage your eyes.

DO NOT use tinted

glasses to enhance the

laser light. Tinted glasses will reduce overall

vision for the application and interfere with the

normal operation of the tool.

Never aim the beam at a

workpiece with a

reflective surface. Bright shiny reflective

sheet steel or similar reflective surfaces are

not recommended for laser use. Reflective

surfaces could direct the beam back toward

the operator.

Use of controls or

adjustments or

performance of procedures other than those

specified herein may result in hazardous

radiation exposure.

The use of optical

instruments with this

product will increase eye hazards.

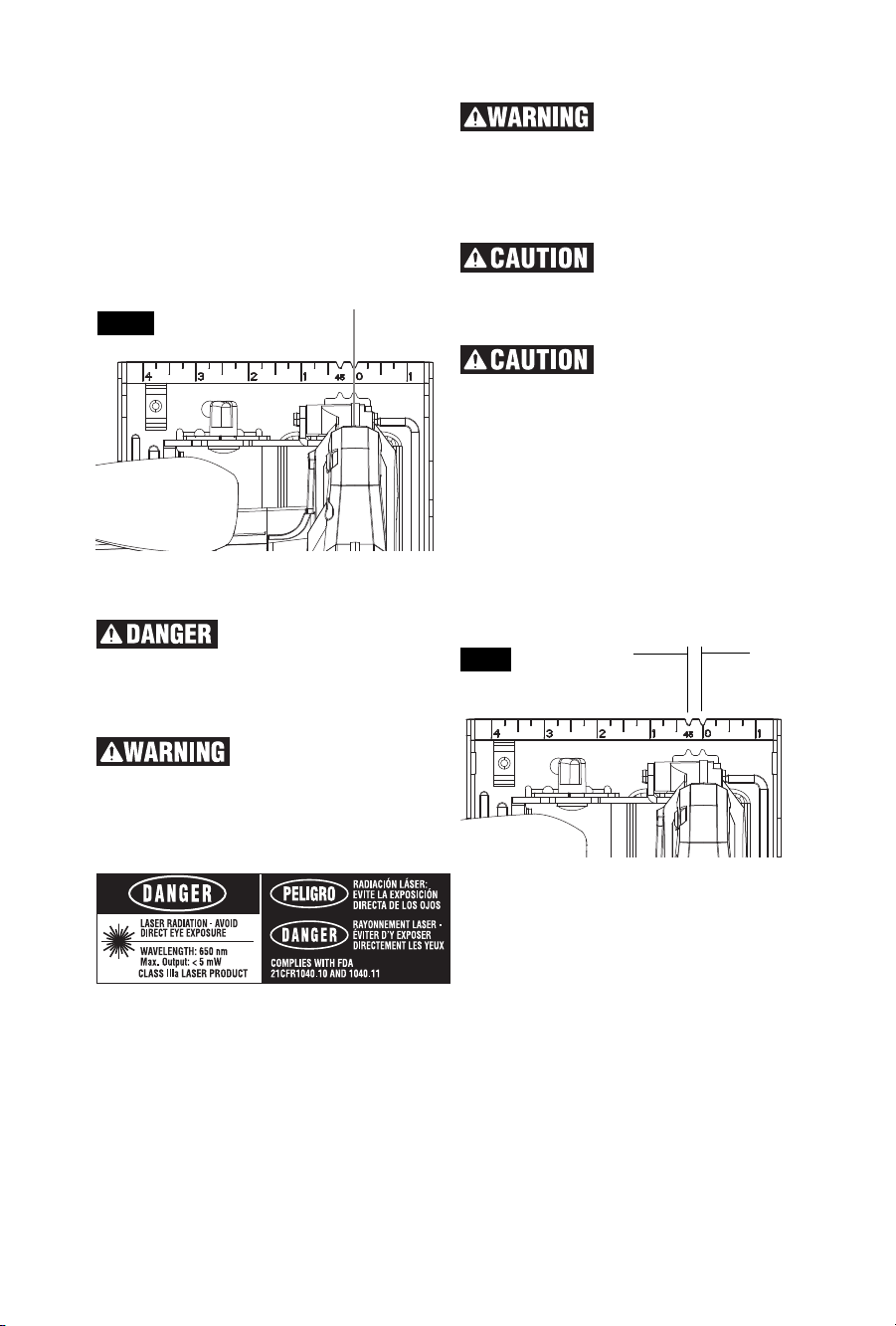

USING THE GUIDE NOTCHES

WITHOUT LASER LINE

For a straight 90° cut, use right side of notch

in the foot. For 45° bevel cuts, use the left side

(Fig. 7a). The cutting guide notch will give an

approximate line of cut. Make sample cuts in

scrap lumber to verify actual line of cut. This

will be helpful because of the number of

different blade types and thicknesses

available. To ensure minimum splintering on

the good side of the material to be cut, face

the good side down.

FIG. 7a

45°

BEVEL

CUTS

90°

VERTICAL

CUTS

FIG. 7