22

Safety instructions

Never clean drive system or control unit with a water hose or

power washer.

• Never clean the drive with alkaline or acidic solutions.

• Carefully remove dirt from drive system and clean push rod from time to

time with a dry cloth.

• If necessary, clean and/or dry.

• Regularly inspect all screws at the fittings and retighten, if necessary.

• Inspect the cover of control unit and readjust, if necessary, to ensure

that it is watertight.

Regular Inspection

• Regularly, at least annually, inspect all safety devices and test their

function (see for example BGR 232, 2003, valid only in Germany).

• Safety devices that are sensitive to pressure (e.g. safety contact unit with

auxiliary monitoring system) should be checked every 4 weeks to ensure

proper functioning, see EN 60335-2-95.

Service and Warranty

The warranty granted complies with statutory requirements. In the event of

a repair that is covered by warranty, please contact your dealer/specialist

stockist. Warranty entitlements only apply to the country in which the

product has been purchased.

Batteries, fuses and light bulbs are not covered by warranty.

Replaced parts remain the property of the service agent.

If you require after-sales service, spare parts or accessories, please con-

tact your dealer/specialist stockist.

We have made every effort to ensure that these instructions are as clear

and concise as possible. However, if you have any queries or wish to com-

ment on this document, please contact us with your suggestions:

Fax: 0049 / 7021 / 8001-403

E-mail: doku@

sommer.eu

Disassembly

Observe safety instructions!

To dismantle the unit, complete the respective steps described in chapter

“Installation” in reverse order. There is of course no need to adjust settings.

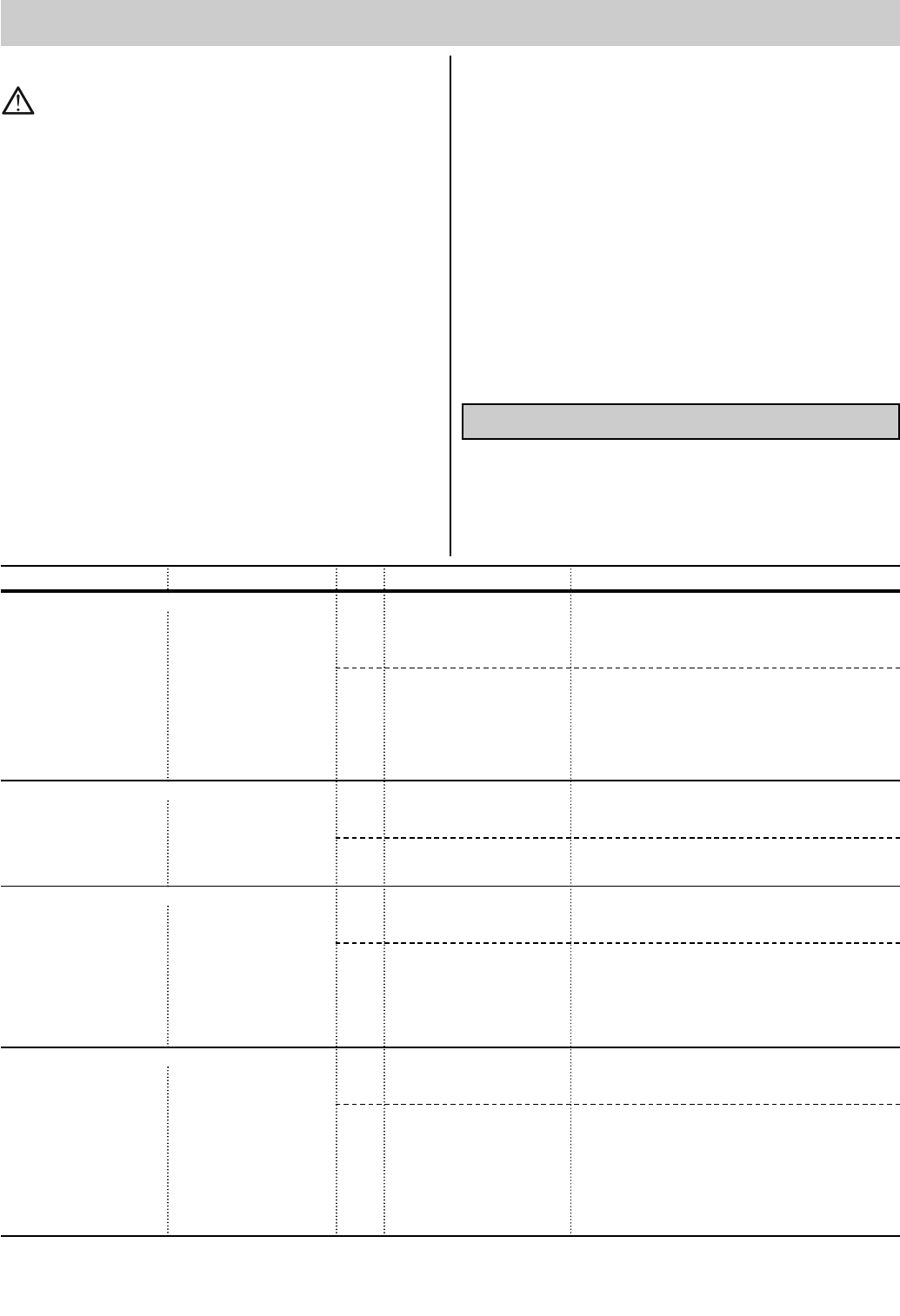

Test Behaviour yes/no Possible cause Remedy

Force cut-off

While the leaf isclosing,

try to stop it by hand. Do

not try to hold the

leaf.

Does gate stop and move in

opposite direction after it

has been halted?

yes • Force cut-off works properly • Do not change settings.

no • Potentiometer at right stop.

Force tolerance set too high.

• Control system defective

• Set force tolerance to lower value by turning the

potentiometer in anticlockwise direction until the test is

successful. Prior to test, open and close the gate twice

watching its operation.

• Shut down the gate and secure against switching on.

Contact customer service!

Emergency release system

Proceed as described in

section “Emergency

Release”.

It must be possible to

open/close the gate by

hand without special effort.

Can the motor be removed

from the shaft?

yes • Everything OK!

no • Gate fittings rusty • Lubricate gate fittings

Safety contact unit (optional)

Open/close gate and inter-

rupt motion by triggering the

safety contact strip.

Gate behaviour according

to settings of

DIP switches

1, 2 and 3.

yes • Everything OK!

no • Cable defective, terminal

screw loose

•

DIP switch settings changed

• Contact strip defective

• Inspect wiring, retighten terminal screws

• Check

DIP switch settings and adjust

• Shut down gate system and secure against inadver-

tent switching on. Contact customer service!

Light barrier (optional)

Open/close gate and

interrupt motion by trigger-

ing the light barrier.

Gate behaviour according

to settings of

DIP switches

1, 2 and 3. Is the LED “SH”

on?

yes • Everything OK!

no • Cable defective, terminal

screw loose

•

DIP switch settings changed

• Light barrier dirty

• Light barrier defective

• Inspect wiring, retighten terminal screws

• Check

DIP switch settings and adjust

• Clean light barrier

• Shut down gate system and secure against inadver-

tent switching on. Contact customer service!

Maintenance