© 2018 Pinnacle Climate T

The gas pressure regulator and hose

assembly supplied with the heater must

be used without alteration.

INSTALLATION

Minimum ventilation requirements: room volume should not

be less than 100 m³; minimum ventilation of 25 cm² per kW of

heat input subject to a minimum of 250 cm².

1.

ensure it is in good condition.

2.

3. Required hose and

regulator is to be 1.5 metres max and 1.0 metre min. in

length, and type EN16129). Connect other end (regulator) to a

fuel supply cylinder.

NOTE: Optimum efficiency is achieved when the heater uses

the appropriate full fuel supply cylinder.

4.

connections with 50/50 soap and water solution prior to start-up

to ensure the heater is connected properly. Soap bubbles

indicate a gas leak. DO NOT use a match or flame to test for

gas leaks.

NOTE: Consult local regulations when planning to install an

air temperature control.

CHANGING

1.

flame-free atmosphere and non-smoking environment.

2. When you need to replace your empty cylinder

first.

3. Make sure that the heater is extinguished completely

4. Remove the regulator from the empty cylinder and change a

new full one.

LIGHTING AND OPERATING INSTRUCTIONS

1. Connect power cord to properly earthed socket. Connect heater

to a proper fuel supply cylinder.

2. Turn gas valve knob on the heater to the “O” (OFF) position.

3. Switch the electrical power switch to ON and check if fan is

operating correctly.

4. Wait five (5) minutes for any gas to clear. Smell for gas. If none

is evident, proceed to the next step.

5. Turn the knob at the fuel supply cylinder counterclockwise to

the OPEN position.

6. Push in the Gas Valve knob on the heater and hold it at least

five (5) seconds. Then turn the knob counterclockwise to the

(1/ ) position. This will light the burner. It may be necessary to

repeat this process a few times to light the heater.

7. Keep the valve knob depressed for at least 30 seconds after

the burner is lit. After 30 seconds release the control knob.

8. If burner does not stay lit, repeat Steps 5 and 6.

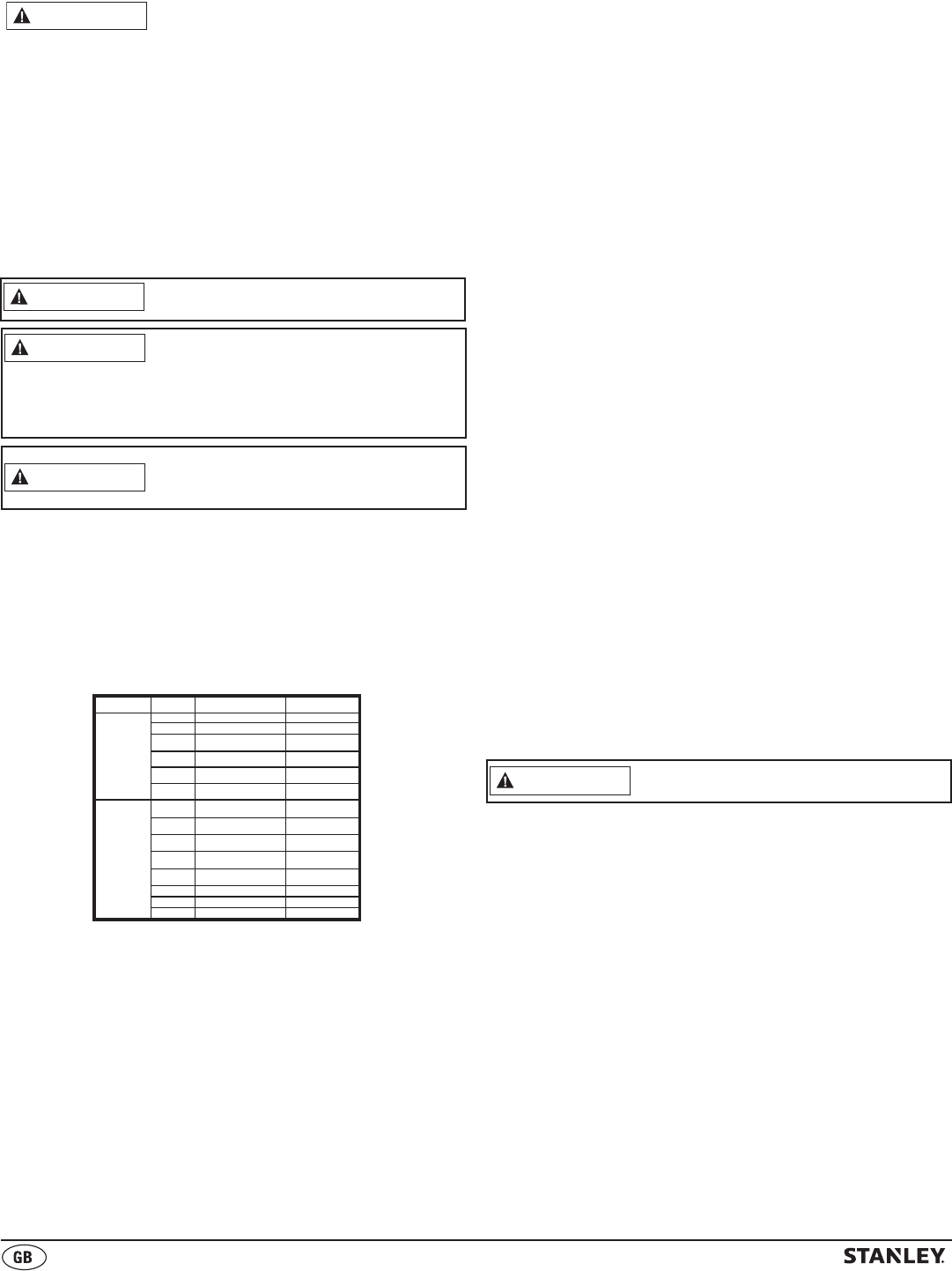

9. Check to see the appliance operating pressure is correct

according to gas chart (below).

SHUTDOWN INSTRUCTIONS

1.

position.

2.

the CLOSED position.

3.

from the fuel supply cylinder.

SERVICING INSTRUCTIONS

These instructions are intended to be used only by competent

persons for carrying out all servicing operations authorized by the

manufacturer

All special tools, materials or servicing aids necessary for the

correct servicing of the appliance shall be specified. Be sure to

check heater for soundness.

- Heater surface temperature must be cold before initiating

service, cleaning or storage.

- Maintenance and repair must be carried out by trained

personnel only at least 2 times per season.

- Before commencing service maintenance disconnect the unit

from the electrical power and the gas supply.

- Check the fuel supply hose condition and change if necessary.

- Check the ignition unit, safety thermostat, and thermocouple

condition and ensure that they are clean. If flame pattern

appears irregular, check nozzle. Wear eye protection when

performing these checks.

- Clean inside the heater unit and the fan blade with compressed

air. Heater is operating correctly when fan is running, flame is

present and soap test showed no leaks.

LONG TERM STORAGE

Always disconnect the heater from the fuel supply cylinder before

putting the heater into storage. If for any reason the heater is to

be stored indoors, the heater MUST be disconnected from the

fuel supply cylinder, and the cylinder stored outdoors in a well-

ventilated area, and out of the reach of children. If appliance is

unable to be left in a safe condition, disconnect the fuel cylinder

from appliance and store separately. The plastic valve plug

or valve cover supplied with the fuel supply cylinder must be

re-installed on the valve to protect the fitting from damage.

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a

person responsible for their safety. Children should be supervised

to ensure that they do not play with the appliance. If the power cord

is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualified persons in order to avoid a hazard.

- NOTE:

in the requirements listed in this manual. In these

cases, contact your local dealer for possible

variations from requirements in this manual.

WARNING

Be careful to avoid torsional stresses in

the flexible tubing (regulator hose).

WARNING

Use the appropriate fuel supply cylinder

listed below.

ST-40-GFA-E : 9 Kg to 45 Kg fuel cylinder

ST-60V-GFA-E : 9 Kg to 45 Kg fuel cylinder

ST-100V-GFA-E : 9 Kg to 45 Kg fuel cylinder

ST-150V-GFA-E : 9 Kg to 45 Kg fuel cylinder

Disconnect heater from fuel supply

cylinder when not in use.

4

I3B/P(50)

/ G30

Destination Country

Gas T

Gas

Category

Model No.

ST-60V

ST-100V

ST-150V

I3+(28-30/37)

/ G30

I3B/P(30) /

G30

I3P(30) / G31

G30 Butane at 28-30 mbar

G31 Propane at 37 mbar

GB, FR, IT, IE

DE

NL, RO, TR

NL, NO, SE, DK, FI, RO, TR,

ES

G30 Butane at 30 mbar

G30 Butane at 50 mbar

I3B/P(37)

G30 Butane at 37 mbar

PL

I3B/P(37)

G31 Propane at 37 mbar

PL

G31 Propane at 30 mbar

I3P(37) / G31G31 Propane at 37 mbar

GB, FR, PT

I3P(50) / G31G31 Propane at 50 mbar

NL, DE

ST-40-GF

I3B/P(37)

G30 Butane at 37 mbar

PL

I3B/P(37)

G31 Propane at 37 mbar

PL

I3B/P(50)

/ G30

DE

I3P(30) / G31

NL, RO, TR

G31 Propane at 30 mbar

I3P(37) / G31

G31 Propane at 37 mbar

GB, FR, PT

I3P(50) / G31

G31 Propane at 50 mbar

NL, DE

I3B/P(50)

/ G30

Destination Country

Gas Ty pe and Inlet Pressure

Gas

Category

Model No.

ST-60V

ST-100V

ST-150V

I3+(28-30/37)

/ G30

I3B/P(30) /

G30

I3P(30) / G31

G30 Butane at 28-30 mbar

G31 Propane at 37 mbar

GB, FR, IT, IE

DE

NL, RO, TR

NL, NO, SE, DK, FI, RO, TR,

ES

G30 Butane at 30 mbar

G30 Butane at 50 mbar

I3B/P(37)

G30 Butane at 37 mbar

PL

I3B/P(37)

G31 Propane at 37 mbar

PL

G31 Propane at 30 mbar

I3P(37) / G31G31 Propane at 37 mbar

GB, FR, PT

I3P(50) / G31G31 Propane at 50 mbar

NL, DE

ST-40-GF

I3B/P(37)

G30 Butane at 37 mbar

PL

I3B/P(37)

G31 Propane at 37 mbar

PL

I3B/P(50)

/ G30

DE

I3P(30) / G31

NL, RO, TR

G31 Propane at 30 mbar

I3P(37) / G31

G31 Propane at 37 mbar

GB, FR, PT

I3P(50) / G31

G31 Propane at 50 mbar

NL, DE

THIS HEATER MUST BE INSTALLED BY

COMTETENT PERSONS IN ACCORDANCE

WITH SUCH REGULATIONS AS ARE IN FORCE.

WARNING