7

EN

21. ST

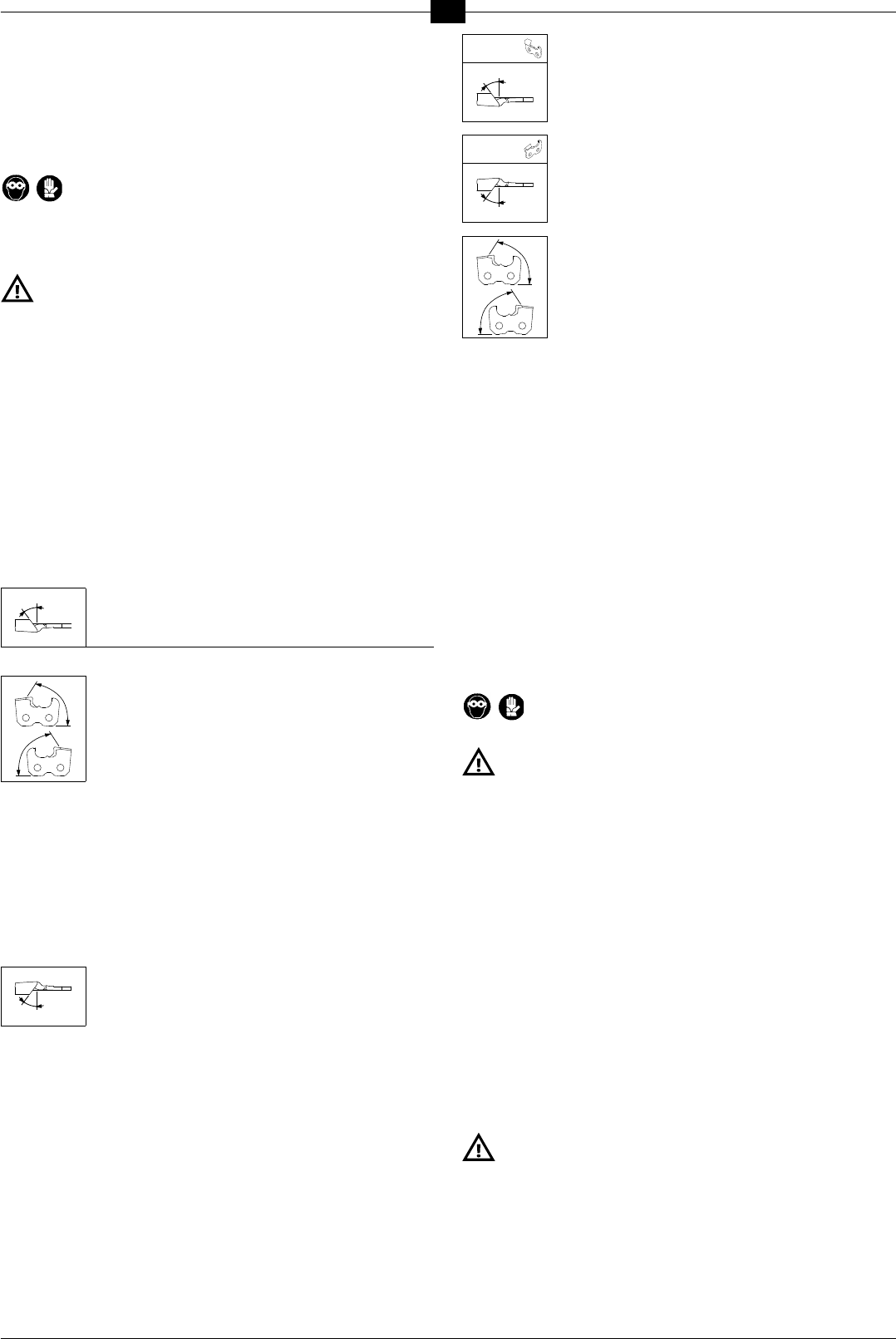

22. CHECKING THE GRINDING WHEEL SHAPE

23. GRINDING WHEEL DRESSING

24. ADJUSTING THE VISE

Get hold of a new section of chain with at least two cutters opposed with the

same gauge as the chain to be sharpened

24.1 RIGHT CUTTER VISE ROT

24.2 RIGHT AND LEFT CUTTER

24.3 ADJUSTING THE CHAIN BLOCKING UNIT (FIG.29)

24.4 POSITIONING THE CUTTER

24.5 LEFT CUTTER VISE ROT

V20a

25. ADJUSTING THE GRINDER

25.1 SHARPENING ANGLES

-

25.2 SETTING THE TOP SHARPENING

“0”

25.3 SETTING THE TOP SHARPENING

“0”

25.4 SETTING THE CUTTING ANGLE (FIG.23)

(right and left cutters)

“0”

25.5 SETTING THE CHAIN BLOCKING UNIT (FIG.29)

25.6 POSITIONING THE CUTTER

from the cutter

26. SHARPENING W

-

-

-

27. SHARPENING THE CHAIN

28. GRINDING WHEEL DRESSING FOR SHARPENING THE DEPTH GAUGE

29. SHARPENING THE DEPTH GAUGE