Connecting the Gas

Connecting the hob to the gas mains

should be done in compliance with the

current installation standards and/or regu-

lations, and by a qualified technician (an

authorised installing engineer). The gas

connection for these hotplates should be

made with rigid piping, because the

appliance is a stationery one, where it is

destined for the EC market. The hob has a

threaded connection of 1/2’’ in diameter

(as per EN ISO 228-1 ) or 1/2’’ with a coni-

cal thread (as per EN 10226-1), depending

on the regulations in the destination

country.

For markets with an EN ISO 228-1 1/2’’

connection, a 10/12 mm copper pipe is

provided as an accessory for welding to

the gas intake pipe.

Ventilation slots should also be made at

the site in compliance with current norms.

Connecting the hob’s gas intake to the

mains should be done in compliance with

the basic gas installation standards for

residential premises.

TEKA assumes no responsibility for any

malfunction or damage that arises from an

incorrect or faulty installation.

In order that the hob is not damaged by

tightening the nut on the gas connection

pipe, a maximum torque of 300 cm * Kgf

should be applied.

When the gas connection has been made,

the installation should be checked to ensu-

re that it is completely sealed. If the check

is done using air, care should be taken that

the test pressure is no more than 200

g/cm² Where air is not available, soapy

water should be applied to ensure that

there are no leaks in the connections. Tes-

ting should never be done using a

flame.

When the hob has been installed, check

that the burner minimums are properly

adjusted. To do this, light the burners and

check that they do not go out if you switch

quickly from the maximum to the minimum.

Whenever the gas connection nut is remo-

ved, its washer should be changed.

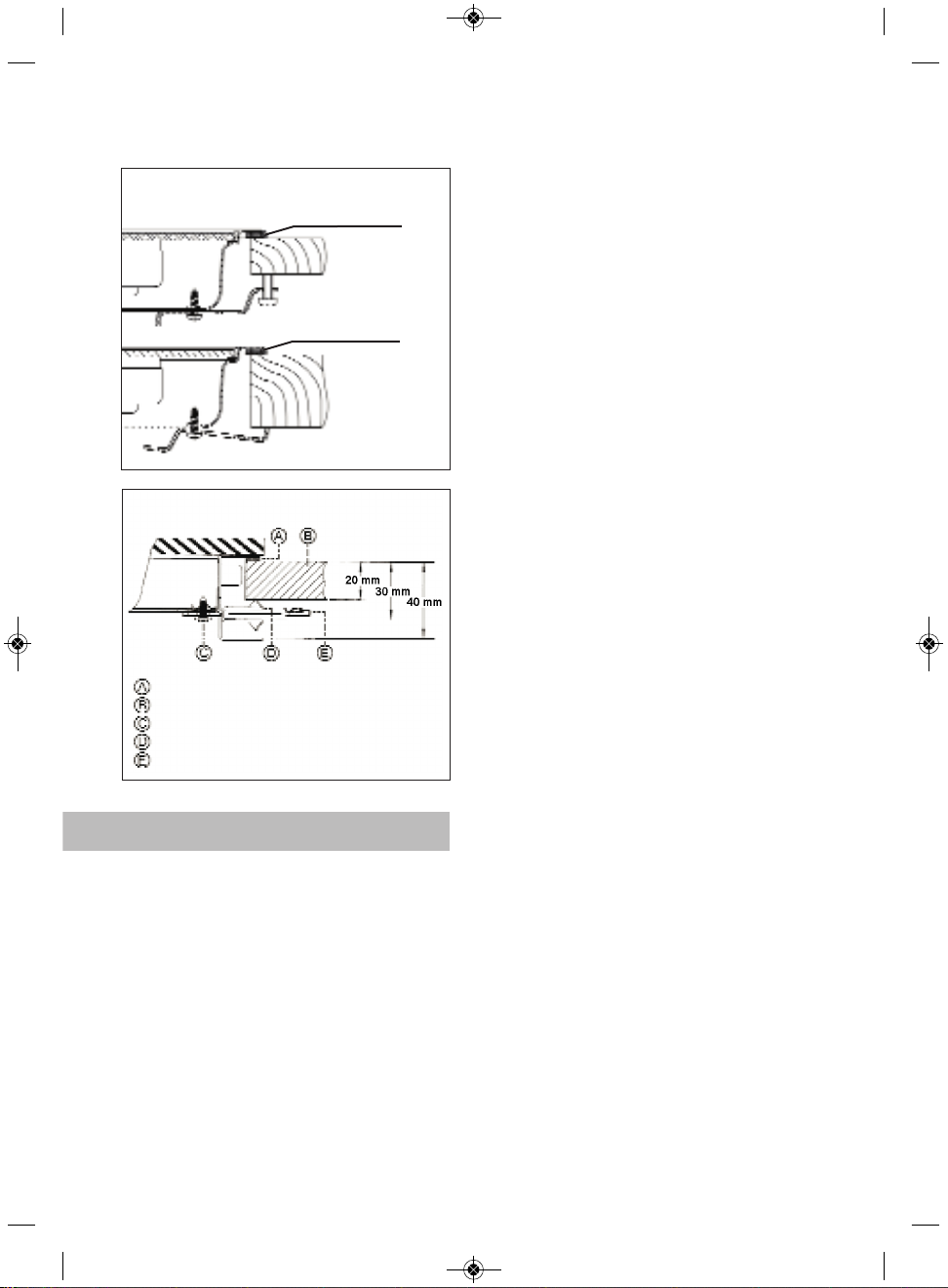

fig. 4

Sealing washer

Sealing washer

fig. 5