58

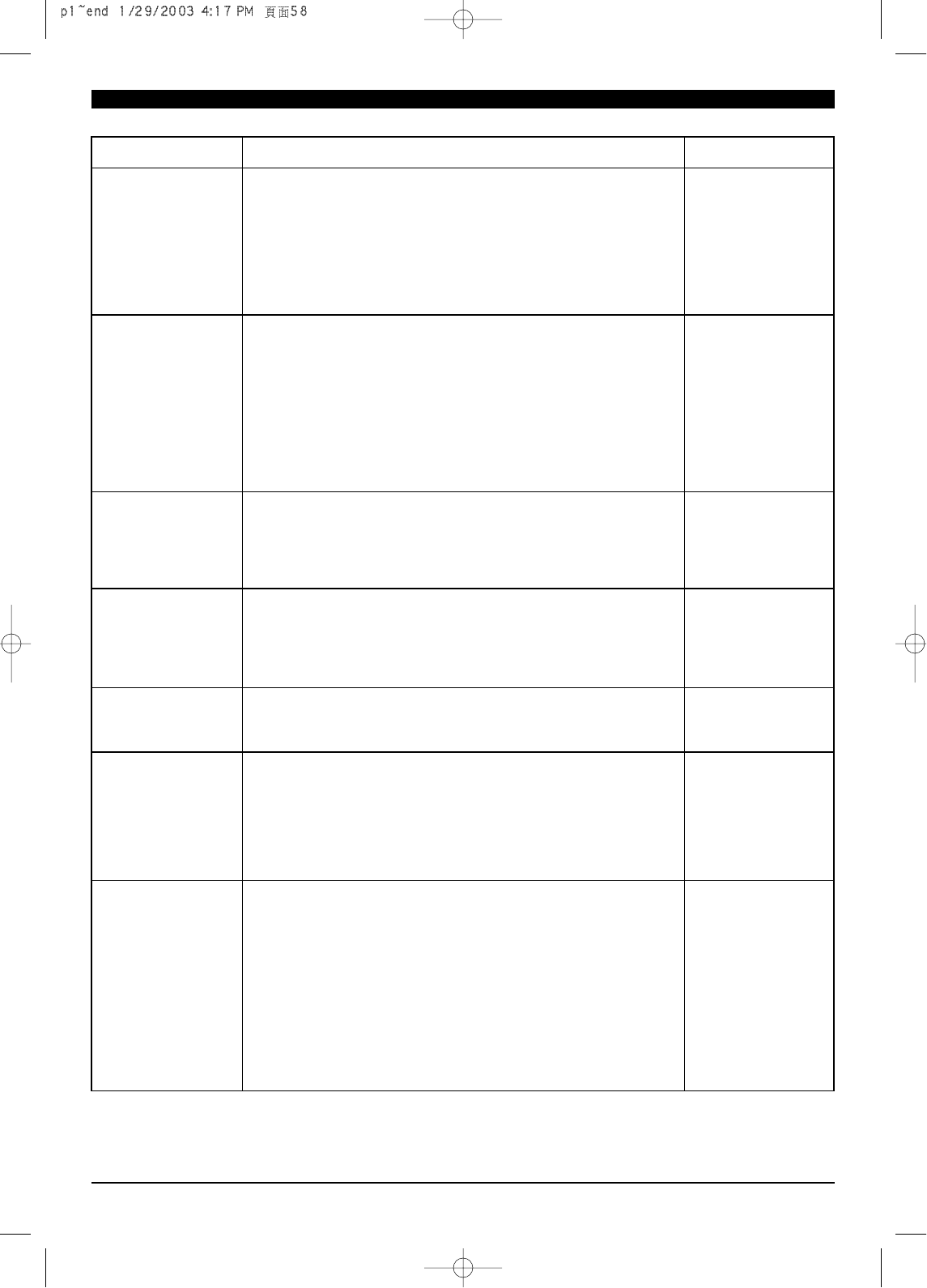

Trouble chart

English

PROBLEM

Breaking lower

thread

Skipping stitches

Irregular stitches

The material not

fed correctly

Noisy machine

The material

puckers

Breaking needle

PROBABLE CAUSE

Thread not wound evenly on the bobbin or not drawn up

correctly

Lower thread tension too tight

Lint is stuck in the bobbin case and inside the tension spring

Needle not fully inserted

Needle bent or blunt

Size or type of needle and thread not suitable for the

material

Incorrect upper threading

Too much oil on the machine

Incorrect size of needle for the material

Upper thread tension is too loose

Incorrect lower thread tension

Pattern selection dial not set correctly

Feed teeth are down

Lint is stuck in the feed teeth

Check the thread in shuttle, even the slightest amount of

thread inside the shuttle may cause noise or binding, use

material like tooth pick or cotton swab to clean

Upper or lower thread tension is too tight

Stitch too long for material

Thread too thick

Incorrect threading of upper or lower thread

Needle not correctly inserted

Needle bent

Needle clamp screw too loose

Upper thread tension too tight

Needle too fine for the material

Dials have been changed while the needle was down in the

material

CORRECTION

P. 12, P.16

P.53 ~ 54

Remove lint and

fluff with a

cleaning brush

P.55

P.55

P.63

P.16

P.52

P.63

P.23

P.53 ~ 54

P.65 ~ 66

P.26

P.57

P.57

P. 23, P.53 ~ 54

P.65 ~ 66

P.63

P. 16, P.13

P.55

P.56

P.55

P.23

P.63

P.65 ~ 66

If trouble is still apparent in the machine, please contact where you purchased or our web.

site (Europe only).

Do not try to correct fault by yourself.