16

Installation of the drive units

1. Fig. A: Remove from packaging all components onto floor.

2. Except from the cross actuation tubes, loosely assemble all

parts together to form a cross-tube assembly. Nuts must be no

more than finger-tight.

3. Fig. B: Place installation kit loosely onto frame of vehicle

and cross strut, with the exception of the stoppers (C – stop-

pers are attached when installation is complete).

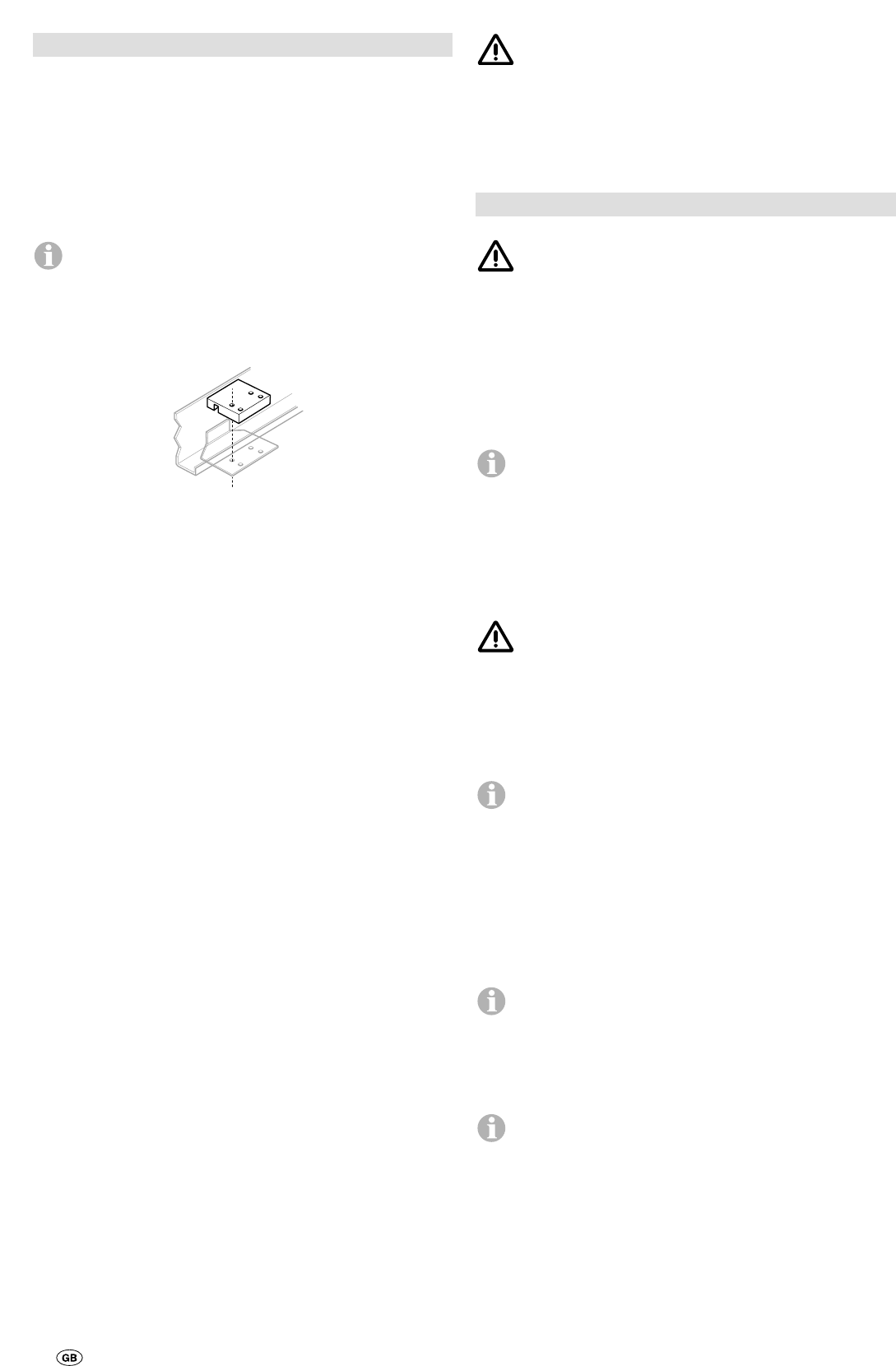

For chassis with U-profile frame, use U-profile frame kit

(Art. no. 60010-09300) instead of clamping plates provid-

ed for standard installation. Fit the two clamping plates to the

frame as shown in the illustration and attach using the U-bolts

and nuts provided in the installation kit. (The provided stoppers

replace the standard stoppers (C) and are attached when

installation is complete.)

Position drive rollers such that they are in front of or behind the

tyres at wheel hub height (middle of wheel). No height com-

pensation is required for the standard installation (frame height

approx.185 mm).

With frame heights of 140 mm to 185 mm, use spacer plate

set (Art. no. 60010-65500) and screw set (Art. no. 60010-

70000) to set the drive rollers to the correct height (middle of

wheel).

For height compensation (as shown in fig. B) clamp 1 to 3

spacer plates (d) between the cross strut and the vehicle

frame (maximum of 3 plates). Use the extended U-bolts for

installation.

For greater height differences, a flat frame kit (Art. no. 60010-

09400) is available from Truma as a special accessory – for

installation see instructions provided with flat frame kit.

In Germany, this flat frame kit installation must be accepted by

a vehicle expert.

4. Fig. C: Create an adequate distance between the chain

guard and the wheels/shock absorbers by moving the drive

units to the side so that they do not come into contact with

each other.

5. Fig. D: Move adjustable middle tube into a central position

and tighten the 2 bolts at the side a little.

Create the correct distance between the tyre and the roller

(15 mm) with the provided spacer by moving the drive units in

the longitudinal direction.

6. When positioned on both sides, lightly tighten the bolts and

clamps. Check the spacing (15 mm) again with the caravan’s

weight on its wheels. Check that there is adequate floor clear-

ance.

7. Re-check the distance of 15 mm from the tyres (with weight

on wheels) and tighten the nuts (28 Nm for W/F 17 mm), then

tighten the 4 bolts of the middle tube (15 Nm).

8. Fig. B: After the Mover is positioned in the correct position,

the 4 stop blocks should be bolted onto the chassis immedi-

ately behind and in front the mounting brackets (17 mm AF to

28 Nm). The stop blocks ensure that the Mover does not move

along the chassis during operation.

When the rollers are engaged with the tyre, the mini-

mum dimension for „a“ and „b“ is 10 mm (see fig. C).

9. Fig. E: Now that the Mover is fitted and secured correctly,

take the remaining tubes for the cross actuation and fit as illus-

trated. The sliding centre tube will allow the width to change to

suit the caravan’s chassis. The outer tubes must be secured on

each side with the 4 grub screws provided.

Installation of motor cables and control unit

Remove battery cable terminals and disconnect any ex-

ternal electrical power before starting work. If you are

unsure about the electrical installation, have it checked out by

a qualified Auto Electrician.

Pre-fitted, each motor has four heavy-duty cables (2 x 6 mm

2

and 2 x 1 mm

2

). All the cables have to be routed along the un-

derside of the caravan floor to the point where the electronic

control unit will be situated. An example of a suitable location

for the relay controller is in a bed stowage box in close proxim-

ity to the manoeuvring aid, at least 40 cm away from the

battery.

The battery connection cable may not be lengthened.

The connecting cables to the motor and the battery must

be separate and must not be routed via the relay box.

1. Fig. F: Attach relay controller (install horizontally with

antenna in a vertical position) to floor of stowage box with

provided screws.

2. Drill a 25 mm hole, approximately 150 mm in front of control

unit for the motor cables.

Take care to avoid any chassis members, gas pipes and

electrical wires)! The connecting cables to the motor and

the battery must not be routed parallel to each other.

3. Route motor connecting cable to relay controller along un-

derbody of caravan and attach to chassis or underbody using

the provided clips and screws. Take care to secure the cables

so they will not chafe on the chassis or sag below the floor

(use supplied protection tubing).

The motors move when the drive rollers are engaged,

so allow a little slack at the motors to avoid the cables

being stretched.

4. Mark the relevant cables and then cut to length according-

ly (before or after the axle, depending on the installation).

Crimp provided spade connectors to the 6 mm

2

cables (fig. H)

and connect in accordance with wiring diagram

(fig. F – red = positive, black = negative).

The 1 mm

2

cables are to be connected to the plug connector

(observe left and right, no need to be concerned about polarity).

Excess cable must be cut to length and not looped inside

the bedding locker. A good quality connection on each

cable is essential!

5. Fig. F and G: Route battery connecting cables (10 mm

2

) to

relay controller and securely attach using the provided clips

and screws.

Route battery connecting cables so that they do not

chafe (particularly at leadthroughs through metal panels).

Use water hoses or leadthrough grommets to prevent damage

to cables. Connect battery connecting cables to the existing

battery terminals (red = positive, black = negative).

6. Re-check whether all cables are correctly connected,

attached using the provided clips and cannot chafe.