8

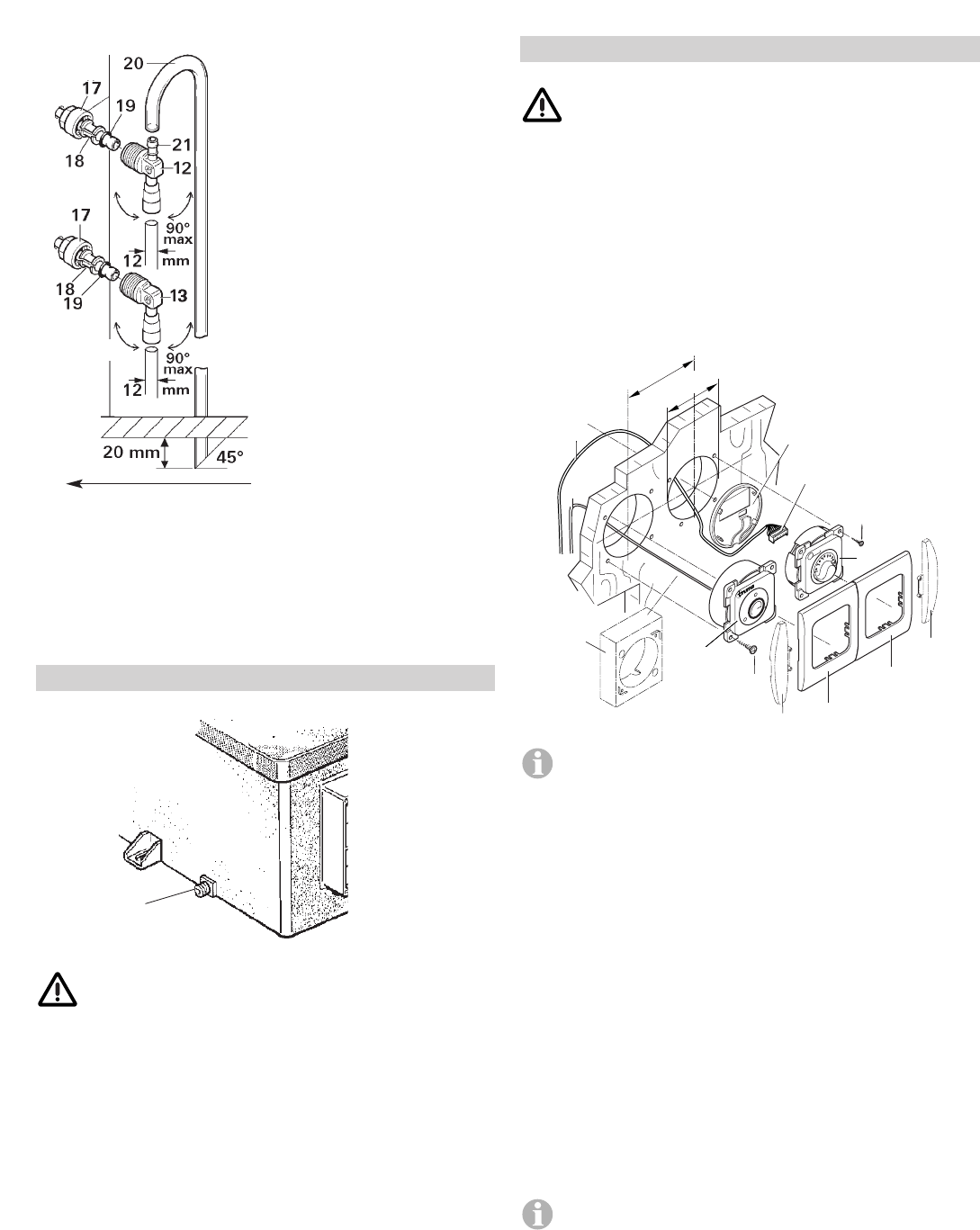

2. Screw elbow with integrat-

ed breather valve (12) to hot

water connection pipe (upper

pipe) and elbow without

breather valve (13) to cold

water connecting pipe (lower

pipe).

Slide on nut (17), tension ring

(18) and O-ring (19). Assem-

ble screw connector and

connecting pipe and fasten

together using nut (17).

Slide ventilation hose with

11 mm outer diameter (20)

onto the breather valve hose

nozzle (21) and route towards

the outside. Do not allow the

radius of the arc to be less

than 40 mm.

Cut off the ventilation hose

approx. 20 mm below the

floor of the vehicle at an an-

gle of 45° to the direction of

travel.

3. Produce connection (22) for cold water supply between

safety/drain valve (14) and elbow (13 – lower pipe) on water

heater.

4. Route the hot water pipe (23) from the elbow with integrated

breather valve (12 – upper pipe) to the hot water consumers.

Gas connection

The operating pressure for the gas supply is 30 mbar

(or 28 mbar butane/37 mbar propane) and must corre-

spond to the operating pressure of the appliance (see name

plate).

The 8 mm gas supply line is connected to the connection noz-

zle (38) with cutting ring connection. The cutting rings are to

be selected according to the gas pipe used (for copper pipe:

support sleeves and brass cutting ring as supplied). Carefully

hold in place with a second wrench when tightening!

Before connecting to the water heater make sure that the gas

lines are free from dirt, chips and such!

Route the pipes in such a way that the appliance can be

removed again for servicing.

In areas frequented by people, keep the number of parting

connections in the gas supply line to an technically feasible

minimum.

The entire system must accord with the technical and adminis-

trative provisions of the individual country of use (e.g. EN 1949

for vehicles). National specifications and regulations must be

respected.

Installation of the control panels

When using control panels which are specific to the ve-

hicle or the manufacturer, the electrical connection must

be established in accordance with the Truma interface descrip-

tions (refer to Electrical connection 230 V). Any modification

made to the Truma components pertaining to this will lead to

the invalidation of the guarantee, as well as to the exclusion of

any claims for liability. The installer (manufacturer) is responsi-

ble for providing instructions for use for the user as well as for

identification printing on the control panels.

When selecting the location, bear in mind that the control pan-

els must not be subjected to direct radiant heat. Length of con-

nection cable 3 m. If required, a cable extension of 5 m can be

supplied (please refer to page 11).

If it is not possible to install the control panels flush with

the surface, Truma can provide a surface-mounting frame

(25) on request, as a special accessory (Part no. 40000-52600).

1. The control panel for gas operation (26) and (if provided) the

control panel for electrical operation (27) should be fitted next

to one another if at all possible (distance between centres of

holes 66 mm).

2. In each case, drill a hole with diameter 55 mm (distance

between centres of holes 66 mm).

3. Plug the control panel cable (28) to the control panel for gas

operation (26) and then fit on the rear cover cap (29) as a

stress-relieving device.

4. Push the cable through to the rear and lay the connection

cable (28 + 30) to the water heater.

5. Lay the connection cable with the orange multipole connec-

tor (28) to the 12 V control electronics unit (for connection see

Point 6, electrical connection 12 V).

6. Secure both control panels with 4 screws (31) each and fit

the cover frame (32) on them.

To round off the appearance of the cover frame, Truma

can provide side pieces (33) as special accessories in

8 different colours (please ask your dealer).