4

Installation of the

safety/drain valve

Fig. B + C: Install safety/drain

valve (13) at a place which is

easily accessible, near the

water heater. Drill hole with

18 mm diameter and pass

through discharge socket

with hose (14). Fasten safety/

drain valve with 2 screws.

The draining is to be directly

to the outside at a position

protected against splash wa-

ter (apply splash guard, if

necessary).

Water pipe routing

1. Fig. B + C: Connect cold

water supply (24) to safety/

drain valve (13). Direction of

flow is unimportant.

2. Fig. D: Screw elbow with

integrated breather valve (15)

to hot water connection pipe

(upper pipe) and elbow with-

out breather valve (16) to cold

water connecting pipe (lower

pipe).

Slide on nut (17), tension ring

(18) and O-ring (19). Assem-

ble screw connector and con-

necting pipe and fasten to-

gether using nut (17).

Slide ventilation hose with

11 mm outer diameter (20)

onto the breather valve hose

nozzle (21) and route towards

the outside. Do not allow the

radius of the arc to be less

than 40 mm.

Cut off the ventilation hose

approx. 20 mm below the

floor of the vehicle at an an-

gle of 45° to the direction of

travel.

3. Fig. B + C: Produce hose

connection (22) for cold wa-

ter supply between safety/-

drain valve (13) and elbow

(16 - lower pipe) on water

heater.

4. Route the hot water pipe

(23) from the elbow with inte-

grated breather valve (15 -

upper pipe) to the hot water

consumers.

4

Installation of the

control panels

Attention: When using con-

trol panels which are specific

to the vehicle or the manufac-

turer, the electrical connec-

tion must be established in

accordance with the Truma

interface descriptions (refer to

Electrical connection 230 V).

Any modification made to the

Truma components pertaining

to this will lead to the invali-

dation of the guarantee, as

well as to the exclusion of any

claims for liability. The installer

(manufacturer) is responsible

for providing instructions for

use for the user as well as for

identification printing on the

control panels.

When selecting the location,

bear in mind that the control

panels must not be subjected

to direct radiant heat. Length

of connection cables 2.5 m.

Control panel,

gas operation

If required, for the gas opera-

tion control panel a cable ex-

tension of 5 m can be sup-

plied (Art. No. 70000-53500).

1. Pass control panel cable

through the cable binder on

the back of control panel.

Connect cable to the control

panel and tighten cable

binder as strain relief.

Fasten control panel using

2 screws and route the cable

to the water heater.

Note: Depending on the in-

stallation, the routing of the

control panel cable can be

done in the other way. This

means first connect to the

water heater and then route

to the control panel.

Truma control panel,

electrical operation

Fig. E: When selecting the

place of location, always

make sure that the control

panel (27) is not exposed to

direct heat radiation.

Drill a hole with 8 mm diam-

eter for leading through the

cable and pass the cable

through the hole. Fasten con-

trol panel with the two

screws and route the cable to

the appliance.

5

Electrical

connection 12 V

Always disconnect the ap-

pliance from the power

supply prior to working on

electrical components. It is

not sufficient to just

switch off at the control

panel!

The appliance must be dis-

connected from the vehicle

main power supply when car-

rying out any electric welding

work on the vehicle body.

Attention: If the connec-

tions are transposed there

is a risk of cable burning.

This also rules out any

guarantee or liability

claims.

Fig F: Unscrew cover (34)

from the electronic control

unit. Slide cable connector of

control panel (28) onto the

p.c.b.. The electrical connec-

tion is made at terminal (35)

(red = positive, blue = nega-

tive), for this purpose press

with a small screwdriver from

above and push in cable from

the front. Connect to fused

vehicle mains (central electri-

cal equipment 5 - 10 A) using

a 2 x 1.5 mm

2

cable.

Negative cable to central

earth. With lengths of over

6 m use a cable 2 x 2.5 mm

2

.

If connecting directly to the

battery, the positive and neg-

ative cable must be fused.

Screw cover (34) back on.

There are to be no other con-

sumers connected to the sup-

ply line!

The water heater fuse,1.6 A

EN 60127-2-3 (slow-acting) is

on the p.c.b. (36).

When using power packs, ob-

serve that the appliance is on-

ly to be operated with safety

extra-low voltage according

to EN 60742!

Note: For the connection of

several 12 V appliances we

recommend the electronically

controlled Truma power pack

NT (Art. no. 39900-01). The

Truma power pack (6 A con-

tinuous current) is also suit-

able for charging lead batter-

ies. Other charging devices

are only to be used with a car

battery acting as buffer. Pow-

er packs and power supply

units must have a stabilised

12 V-output (ripple content

less than 1 Volt).

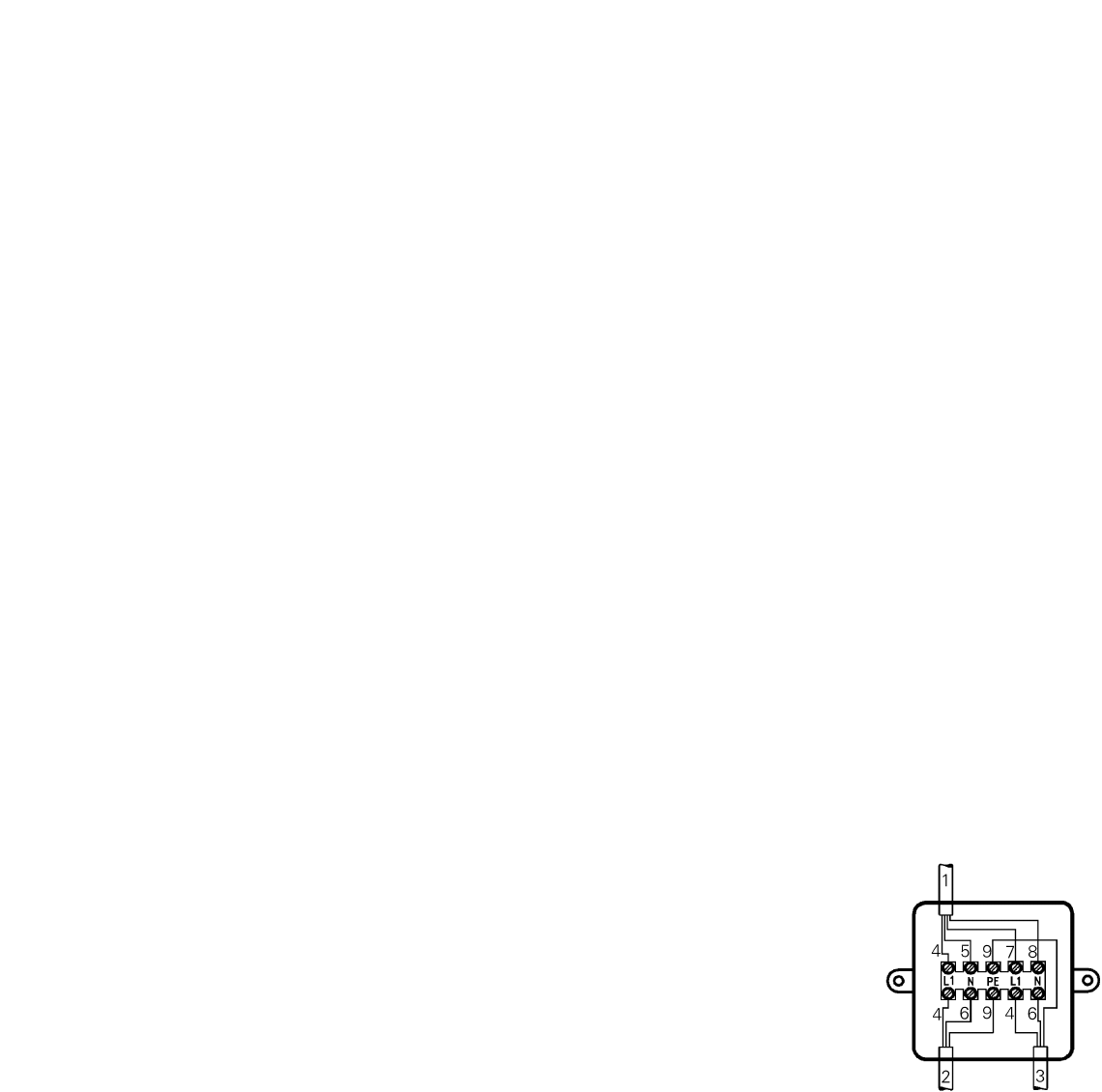

6

Electrical

connection 230 V

Attention: The electrical con-

nection is only to be carried

out by an expert (in Germany,

acc. to VDE 0100, Section

721). The information given

here is not intended as infor-

mation for the layman, rather

it is to for assisting the as-

signed expert, as additional

information, when connect-

ing the appliance!

The connection to the power

supply is by means of a cable

3 x 1.5 mm

2

(e.g. flexible

sheathed cable H05VV-F) to a

splitting box (not included in

scope of delivery).

Always pay attention to con-

nect carefully with the correct

colours!

For maintenance and repair

work a disconnecting device

must be provided on the vehi-

cle for all-pole disconnection

from the power supply, with

at least 3 mm contact clear-

ance.

Connection 230 V with

Truma control panel

1. Connect control panel ca-

ble, supply line 230 V and

heating element cable as

shown in the drawing.

1 = Control panel cable

2 = Supply line 3 x 1,5 mm

2

3 = Heating element cable

4 = brown

5 = green

6 = blue

7 = yellow

8 = white

9 = yellow/green

2. Assemble the splitting box

(Fig. E: 37) on the vehicle

floor or on the wall, in the

vicinity of the appliance (ob-

serve cable length 150 cm!).

Note: All cables must be

secured with cable clips.