manual feeding during the operation of the heating device cannot be activated.

If your heating device is equipped with a pressure safety switch, simultaneously with the feeder, the

combustion fan will also be activated.

Checking the time to service

Fumis Premium allows you to check the time when you should contact the service personnel to perform

regular maintenance on your combustion system. This value is read-only and can be modified by authorised

personnel only.

To check the time to service, follow the steps below:

- Touch the screen (if currently in idle mode) to exit from the idle mode. If the display currently is not in

idle mode, skip this step.

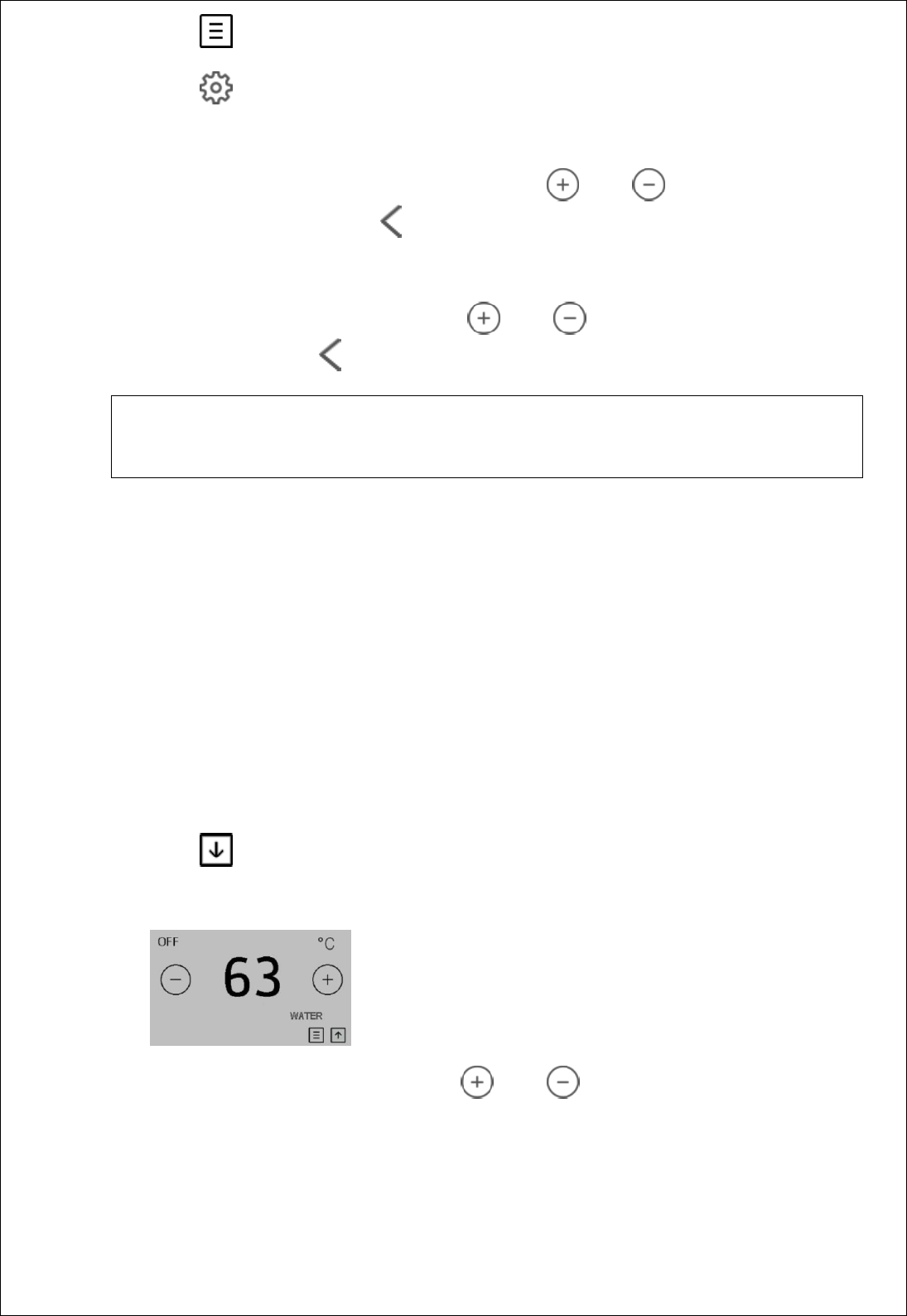

- Tap on to enter the temperature menu

- Tap on to enter the main menu

- Tap on to enter the settings menu

- Navigate to the ''Timo to service'' by tapping on and/or

- Tap on ''Timo to service'' to see the remaining Time to service

Note:

When the time to service expires, the Fumis Premium warns you by displaying the A002 alert (Call service

for regular maintenance). The heating device is still operational. To reset this alert, call authorised

personnel.

If your heating device does not require regular maintenance, the Time to service option is skipped in the

settings menu.

Using the screen lock function

Fumis Premium allows you to lock the screen in order to prevent accidental changes of the settings. With

the screen lock enabled, you can navigate the menu to display current values, but you cannot edit any of the

settings, except the screen lock itself. Note that this option does not disable the Fumis IR (Infra Red) remote

control. The screen lock setting offers the following options:

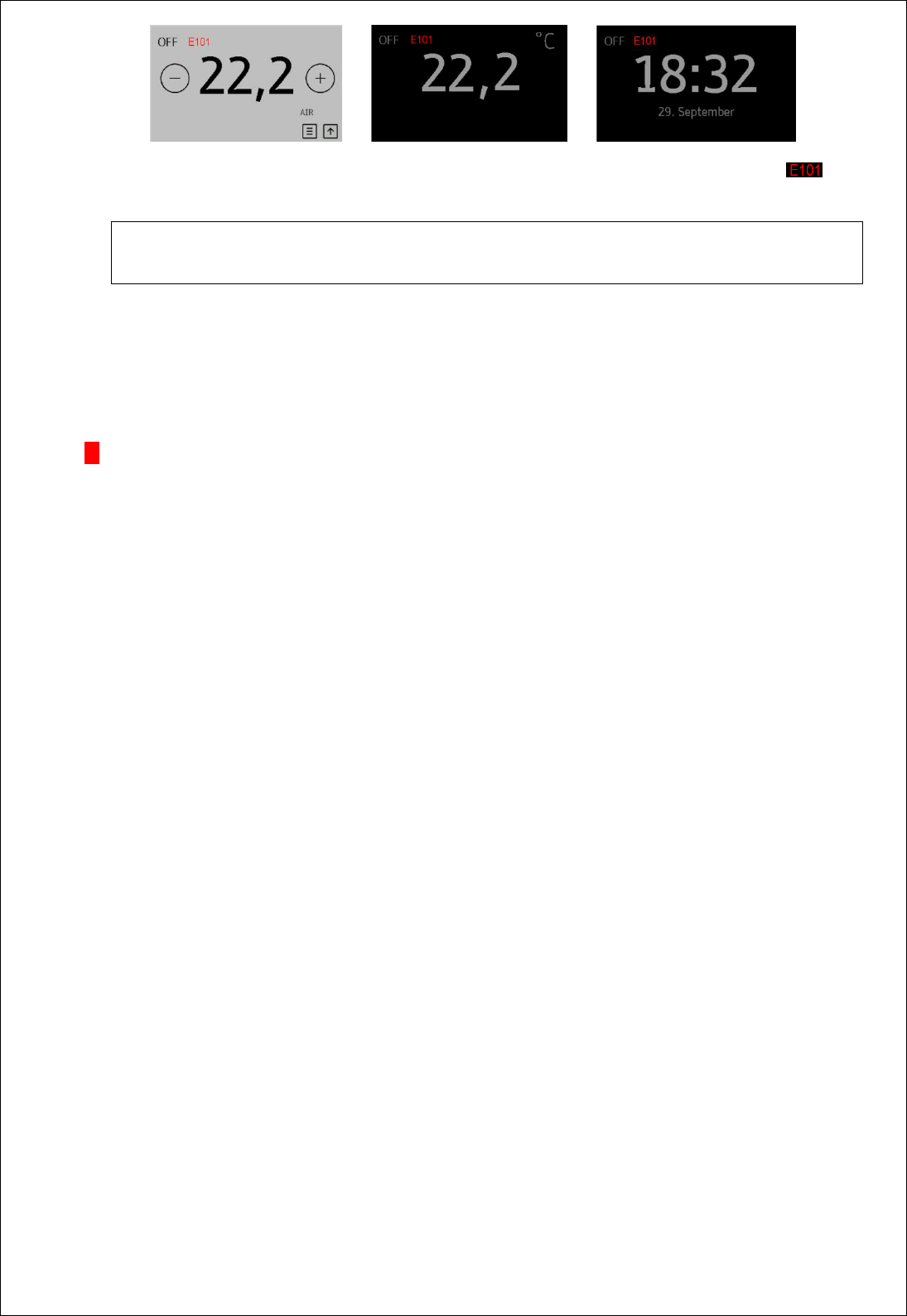

OFF: the screen lock is disabled, all functions are available

Lo: impossible to change settings, only possible to turn ON/OFF the heating device. When this option is

selected, the black icon appears in idle screen and main menu screen.

Hi: all the functions are locked (also turning ON/OFF the heating device), only return to Lo or OFF option is

enabled). When this option is selected, the red icon appears in idle screen and main menu screen.

Tip

We recommend you use the screen lock option if children are able to access the keyboard without adult

supervision.

To use the screen lock function, follow the steps below: