POWX155 EN

Copyright © 2020 VARO P a g e | 10 www.varo.com

9.3 Switching on and off (Fig. 13)

▪ This machine is fitted with a “No Volts Switch”. In the event of a mains power failure or if

the mains plug is removed from the mains supply socket before the machine is switched

off. The machine will not restart without warning when the mains supply is restored or the

mains plug is reconnected to the mains supply, until the machine is switched ON at the

ON//OFF switch (11) fitted to the machine.

▪ To start the machine press the green ON button.

▪ To stop the machine, press the red OFF button (Fig. 13).

9.4 Using the laser

The laser beam is used to indicate the centre location of the drill hole in case you have to drill

several holes in workpieces of the same thickness.

▪ Place the table (8) in a horizontal position. Make sure that the drill and the opening in the

table are aligned.

▪ Place the workpiece on the table.

▪ Lower the drill bit until it touches the workpiece. Switch the laser on by operating the on/off

switch.

▪ Check that the laser cross hairs align with the centre of the drill hole as marked on the

workpiece. If necessary, adjust the laser by hand after loosening the screws with a

screwdriver. When aligned, perform a drill hole.

▪ After use, switch of the laser.

9.5 Feed depth adjustment (Fig. 14)

▪ This facility is useful if a number of uniform depth holes are required in a work piece.

▪ Set the work piece to be drilled in your machine vice.

▪ Insert the drill required into the chuck (9). Bring the drill bit into contact with the work

surface.

▪ Using the depth stop nuts and the depth scale, set the depth of hole required, secure the

depth stop nuts. The drill will stop at the required depth every time (Fig. 14).

▪ NOTE: always stop feeding while the depth stop nuts stops, otherwise the red plastic

collar might be damaged.

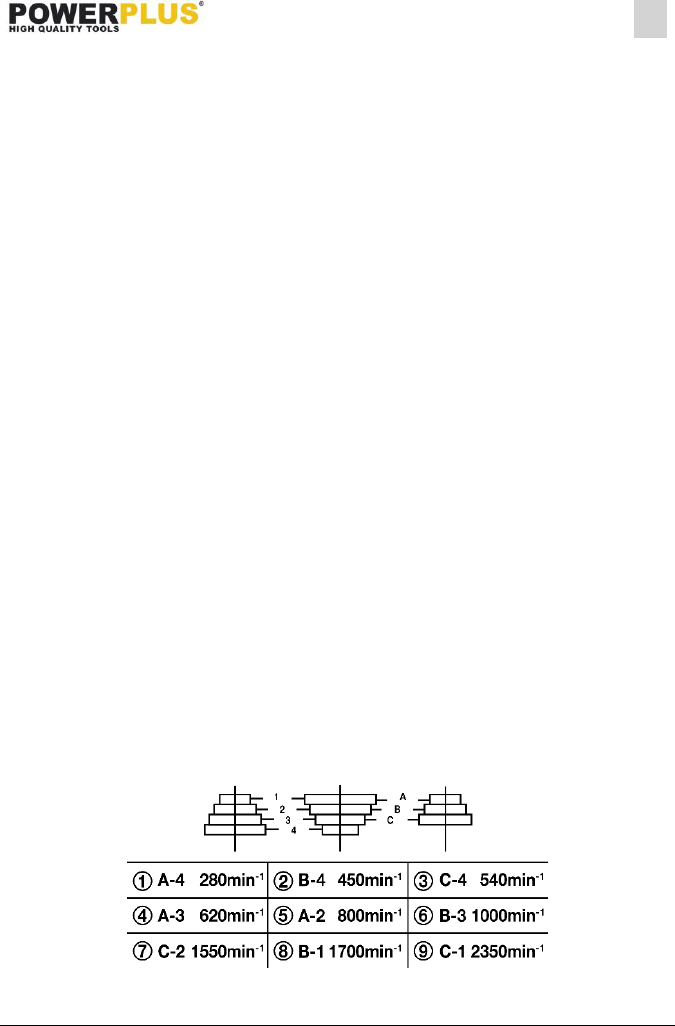

9.6 Changing the spindle speed (Fig. 15)

▪ Warning: always ensure that the tool is switched off and unplugged from the power

supply before making any adjustments or changing a drill bit.

▪ Unscrew the cross head screw (13) securing the pulley guard (1) and lift open the pulley

guard (1) to expose the pulley system.

▪ Determine the spindle speed required.

▪ Identify the pulley arrangement that gives the nearest spindle speed to that required by

referring to the drill speed chart (Fig. 15).

9.7 Drill speed chart