06 Maintenance and specifications

Wheels and tires

06

266

* Option/accessory, for more information, see Introduction.

WARNING

•

The jack must correctly engage the jack

attachment.

•

Be sure the jack is on a firm, level, non-

slippery surface.

•

Never allow any part of your body to be

extended under a vehicle supported by

a jack.

•

Use the jack intended for the vehicle

when changing a tire. For any other job,

use stands to support the vehicle.

•

Apply the parking brake and put the

gear selector in the Park (P) position.

•

Block the wheels standing on the

ground, use rigid wooden blocks or

large stones.

•

The jack should be kept well-greased

and clean, and should not be damaged.

•

No objects should be placed between

the base of jack and the ground, or

between the jack and the attachment

bar on the vehicle.

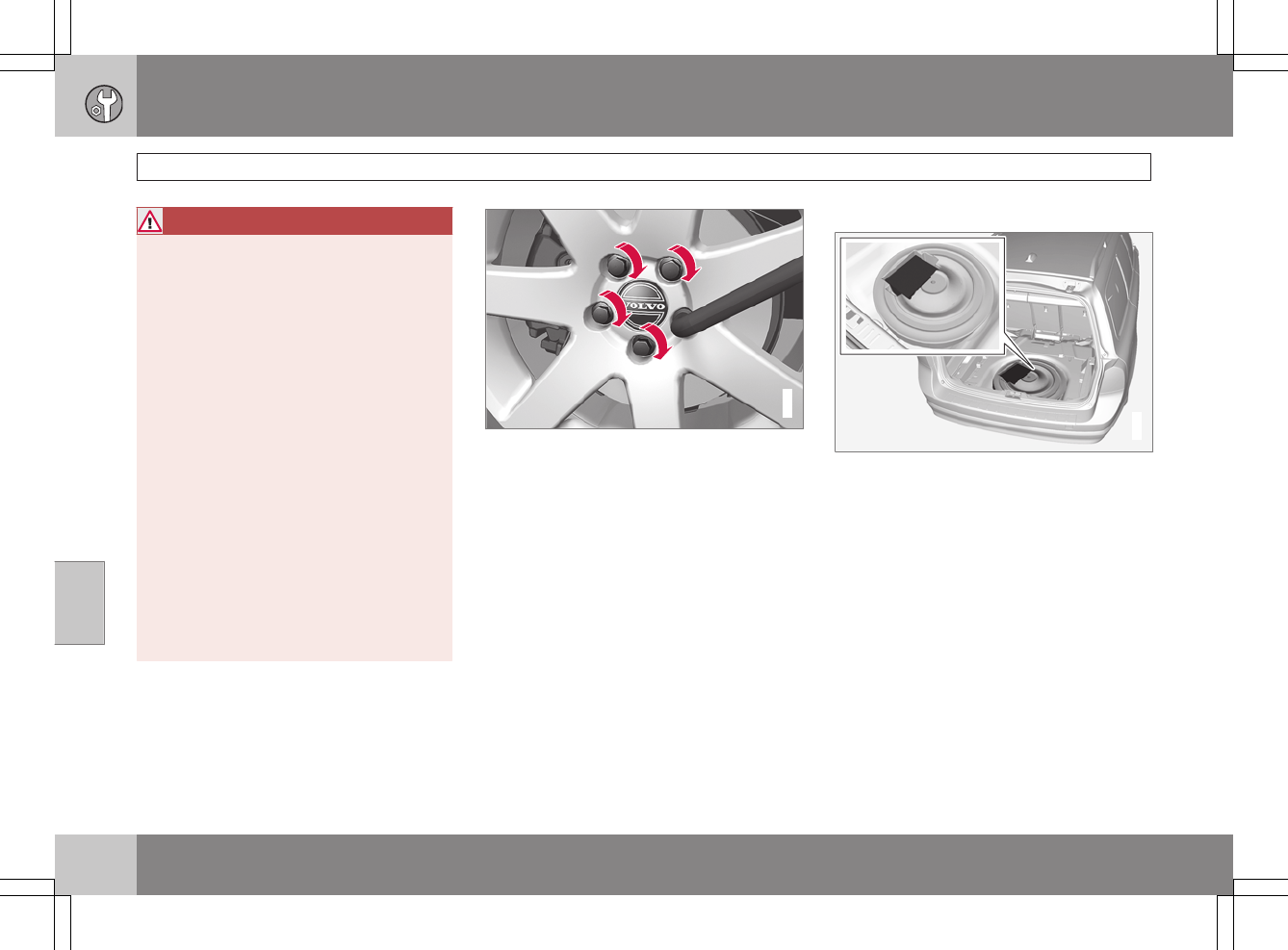

Re-installing the wheel

1. Clean the contact surfaces on the wheel

and hub.

2. Lift the wheel and place it on the hub.

Tighten the lug nuts

3. Install the wheel nuts and tighten hand-

tight. Using the lug wrench, tighten cross-

wise until all nuts are snug.

4. Lower the vehicle to the ground and alter-

nately tighten the bolts crosswise to

102 ft. lbs. (140 Nm).

5. Install the wheel cap (where applicable).

Tire Sealing System

Introduction

Certain models are equipped with a tire sealing

system that enables you to temporarily seal a

hole in the tread surface and re-inflate a flat tire,

or to adjust a tire’s inflation pressure.

The system consists of an air compressor, a

container for the sealing compound, wiring to

connect the system to the vehicle’s electrical

system via one of the 12-volt sockets, and a

hose used to connect the system to the tire’s

inflation valve.

The 12-volt sockets are located in the front

tunnel console, on the rear side of the center

console in the rear seat, and in the cargo com-

partment*.See page 199.