9. The exhaust duct should be as short and straight as possible. The diameter of the

exhaust hose should be at least 120/150 mm (look at chapter TECHNICAL DATA).

Otherwise you have to expect increased noise and decreased performance of your

appliance.

10. The proper maximum bending angle outwards is 120

0

.

11. Use smooth tubes or flexible, non-inflammable exhaust hoses only.

12. When the exhaust duct is connected horizontally, a minimum falling gradient of

1 cm/m or an inclination of 2

0

is required. Otherwise condensate will get into the

motor of the hood.

13. When an exhaust duct is used, the ending of the exhaust hose must be adjusted

into the direction of flow.

14. If the exhaust duct passes through cool areas (e.g. an attic), a temperature gradient

may occur in the different parts of the exhaust duct so condensate will be

generated. Proper insulation of the corresponding parts of the exhaust duct will

then be needed. Equip such an exhaust duct with a condensate trap if need be.

15. Depending on the model the hood is equipped with one (top) or two (top,

back) outlets.

16. The idle outlet is covered by a plastic cap. You can remove this cap by turning it

anticlockwise. Use the cap to cover the idle outlet.

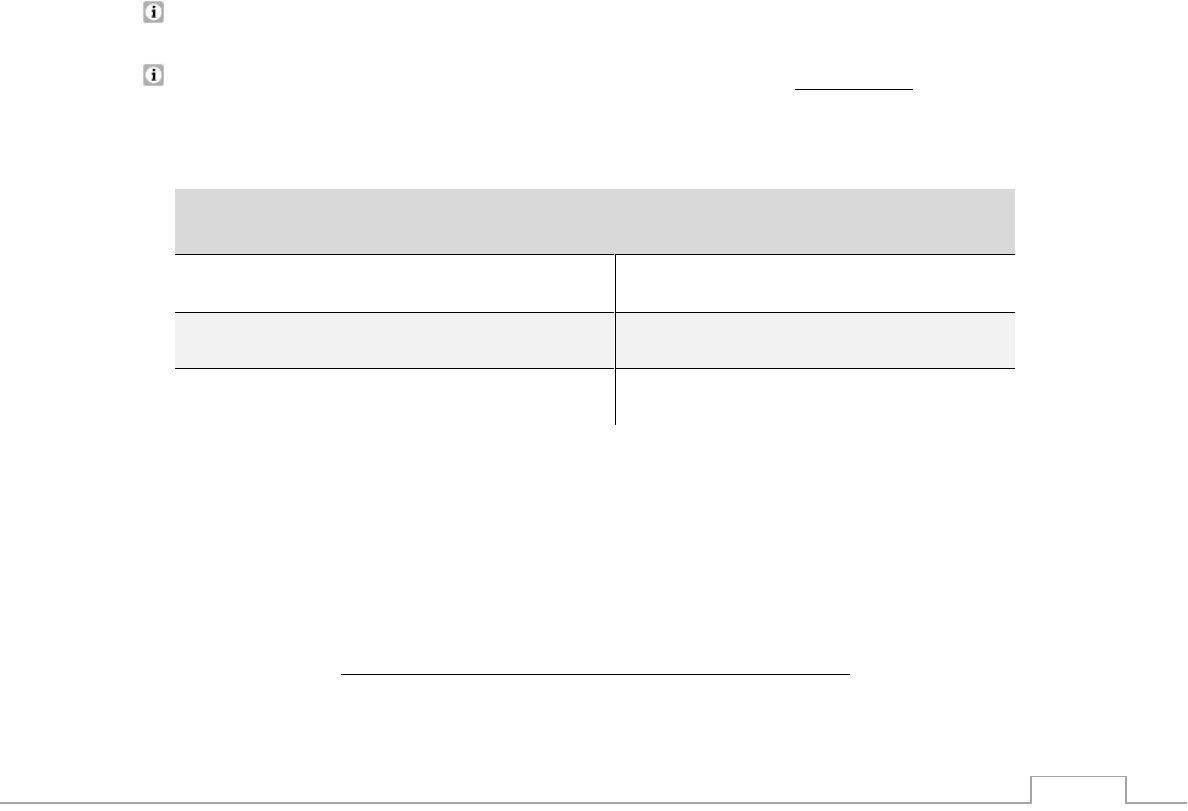

2.1 Minimum distances

Strictly observe the minimum distance between hood and hob.

It is also absolutely necessary to observe the individual minimum

distances to extractor hoods which are specified in the instruction manual

of your hob / oven / etc.

1. The minimum distances do not represent the required total height but a minimum

value generated by adding the height of the hob (floor ↔ hob) and the required

minimum distance of the hob to the extractor hood (hob ↔ extractor hood)