EC083000

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format. The infor-

mation has been complied to provide the mechanic with an easy to read, handy reference that con-

tains comprehensive explanations of all disassembly, repair, assembly, and inspection operations.

In this revised format, the condition of a faulty component will precede an arrow symbol and the

course of action required will follow the symbol, e.g.,

• Bearings

Pitting/Damage ≥ Replace.

EC084002

HOW TO READ DESCRIPTIONS

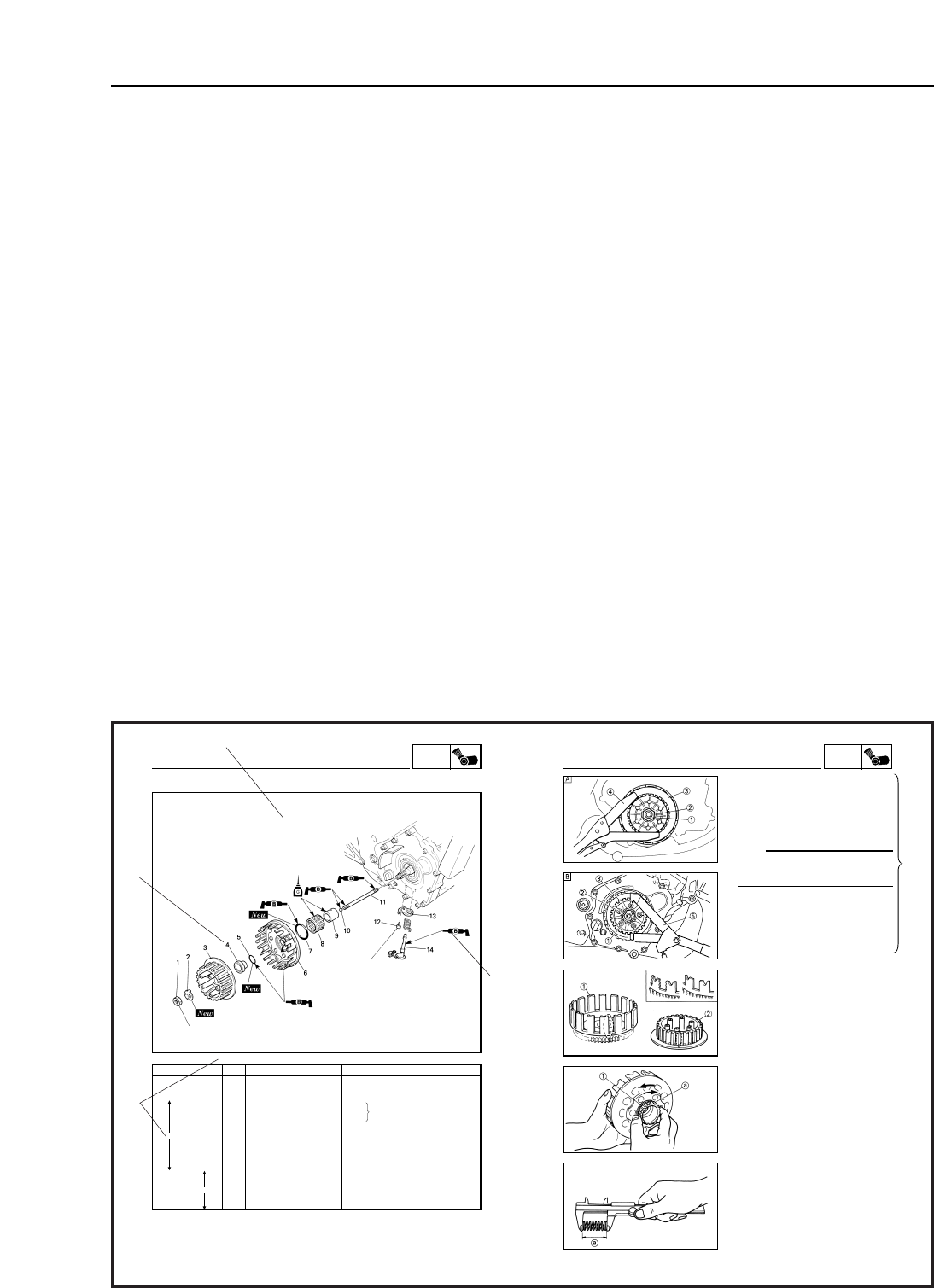

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

1. An easy-to-see exploded diagram

1 is provided for removal and disassembly jobs.

2. Numbers 2 are given in the order of the jobs in the exploded diagram. A number that is

enclosed by a circle indicates a disassembly step.

3. An explanation of jobs and notes is presented in an easy-to-read way by the use of symbol

marks 3.The meanings of the symbol marks are given on the next page.

4. A job instruction chart 4 accompanies the exploded diagram, providing the order of jobs,

names of parts, notes in jobs, etc.

5. Extent of removal 5 is provided in the job instruction chart to save the trouble of an unneces-

sary removal job.

6. For jobs requiring more information, the step-by-step format supplements 6 are given in addi-

tion to the exploded diagram and job instruction chart.

CLUTCH

4-25

ENG

EC4A8100

CLUTCH HOUSING AND PUSH LEVER AXLE

Extend of removal: 1 Clutch housing removal 2 Push lever axle removal

Extend of removal Order Part name Q’ty Remarks

CLUTCH HOUSING AND

PUSH LEVER AXLE

REMOVAL

1 Nut (clutch boss) 1

2 Lock washer 1

Use special tool.

3 Clutch boss 1

Refer to “REMOVAL POINTS”.

4 Spacer 2 1

5 O-ring (small) 1

6 Clutch housing 1

7 O-ring (large) 1

8 Bearing 1

9 Spacer 1 1

10 Ball 1

11 Push rod 1

12 Bolt (seat plate) 1

13 Seat plate 1

14 Push lever axle 1

T

50 Nm (5.0 mdkg, 36 ftdlb)

T

11 Nm (1.1 mdkg, 8.0 ftdlb)

2

1

CLUTCH

4-26

EC4A3000

REMOVAL POINTS

EC483211

Clutch boss

1. Remove:

• Nut 1

• Lock washer 2

• Clutch boss 3

NOTE:

Straighten the lock washer tab and use the

clutch holding tool 4, 5 to hold the clutch

boss.

Clutch holding tool:

YM-91042 . . . . . . . . . . . . . . . .

44

90890-04086 . . . . . . . . . . . . .

55

B

A For USA and CDN

B Except for USA and CDN

EC4A4000

INSPECTION

EC484100

Clutch housing and boss

1. Inspect:

• Clutch housing 1

Cracks/Wear/Damage ≥ Replace.

• Clutch boss 2

Scoring/Wear/Damage ≥ Replace.

EC4A4100

Clutch housing

1. Check:

• Circumferential play

Free play exists ≥ Replace.

• Gear teeth a

Wear/Damage ≥ Replace.

• O-ring 1

Damage ≥ Replace.

EC484400

Clutch spring

1. Measure:

• Clutch spring free length a

Out of specification ≥ Replace springs as

a set.

Clutch spring free length:

Standard <Limit>

36.0 mm (1.417 in) 35.0 mm (1.378 in)

{

ENG