SETTING

7-3

Next run a few laps of the circuit with this

setting and check for any difference in

engine revolutions. If no difference is

noticed, use a main jet with a much smaller

calibration number.

Example: #540 ≥ #500

Factory-set main jet #560

w

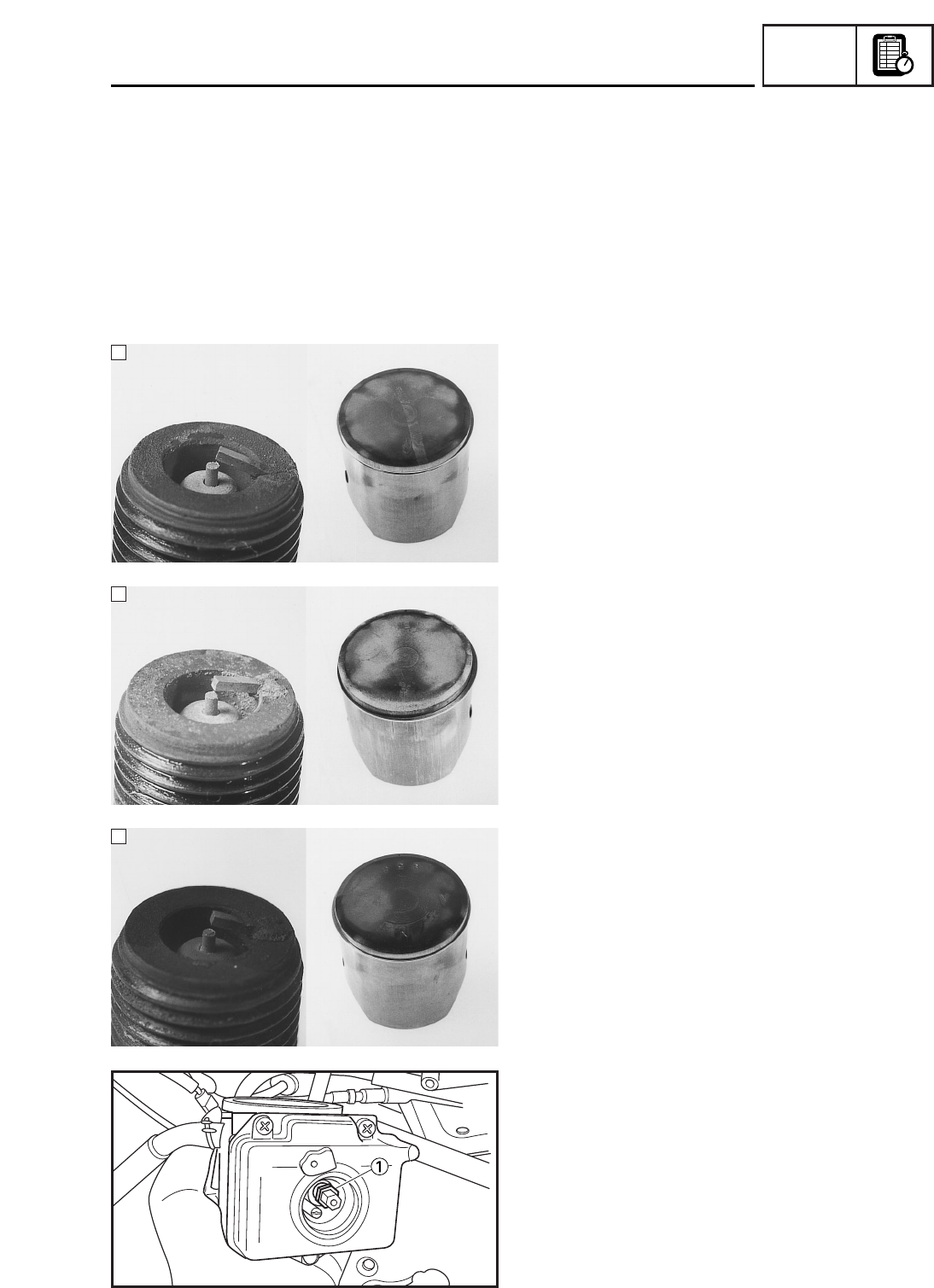

2. Checking of spark plug and piston for dis-

coloration

Repeat the adjustment in the above “1”

several times. If the engine begins to run at

more than 12,000 rpm at full throttle, pro-

ceed to the “spark plug chopping” step

(refer to P7-9) to check for the discoloration

of the spark plug(s) and piston(s).

Refer to the photo for judgment on the dis-

coloration.

As a novice will find it difficult to determine

how much smaller number main jet can be

used just by looking at discoloration, he

should consult an experienced person for

his own experience, too.

Whether the setting is proper or not can be

judged by engine revolutions.

Approximate criteria for such judgment are

given below, on condition that the sec-

ondary reduction ratio is fit for conditions of

the circuit.

•13,000 rpm in 1st and 2nd

•12,500 rpm in 5th and 6th

A Normal

B Over burned (too lean)

C Oil fouled (too rich)

3. Adjustment of main nozzle

The main nozzle 1 adjustment follows the

completion of the adjustment of the main

jet. Check that engine revolutions smoothly

respond to throttle opening from where

throttle is about to be opened to 1/2 throttle

opening. Use a main nozzle of a smaller

size if engine revolutions appear to falter at

the beginning of throttle opening and then

suddenly respond to further throttle open-

ing.

Example:S-4 ≥ S-3

TUN

A

B

C