19

ENGLISH

18

the body. T

work in a well ventilat

safety equipment, such as dust masks tha

designed to filter out micr

Observe the relevant guidelines for your mat

application and plac

health and safety r

Collect the gener

deposits in the surrounding are

for special work (see chapt

the environment in an uncontr

extr

Reduce dus

- For eicient dus

M-class vacuum cleaner tog

- Do not direc

stream at your

- Use an extr

- Ensure good ventila

using a vacuum cleaner Sweeping or blowing stir

- Vacuum or wash the pr

Do not blow

. OVERVIEW

See page 2.

1 Bar auxiliary handle *

2 Thumb screws of the bar auxiliary handle *

3 Locking discs of the bar auxiliary handle *

4 Threaded holes on g

5 2-hole spanner

6 Adjusting nut

7 Diamond cup wheel*

8 Support flange

9 Spindle

10 Spring-mounted ring brush

11 Spindle locking button

12 Ex

13 Opening segment (for working close t

14 Safety guard

15 Handle

16 T

17 Electronic signal indica

18 Speed adjustment wheel

* depending on equipment/not in scope of delivery

. INITIAL OPERA

Before plugging in the machine, check that the

ra

specified on the ra

Austr

(RCD) prot

30 mA or less.

6.1 Fitting of b

Always work with the b

att

illustr

- Fit locking discs (3) to the le and right of the ge

housing.

- Fit the bar auxiliary handle (1) at the gear housing.

- Insert the thumb screws (2) le and right into the bar

auxiliar

- Adjust the bar auxiliary handle (1) to the requir

- Firmly tighten the thumb screws (2) to the le and right

manually.

6.2 Dust e

Always use a suitable dus

Connect an M-class vacuum cle

connection piec

the connecting sleeve 6.30796. We r

antist

. A

Disconnect the mains plug bef-

ries. The machine must be switched o and the spindle

must be at a s

7.1 Locking the spindle

Press in the spindle locking knob (11) only when the

spindle is stationary!

- Press in the spindle locking butt

spindle (9) by hand until you feel the spindle locking

button eng

7.2 Fitting/removing the diamond cup wheel

See illustr

T

- Fit the support flange (8) on the spindle. (9) The flange

should not turn on the spindle when properly att

- Lay the diamond cup wheel (7) on the support flange (8)

so that it lies flat along the support flange.

- The two sides of the clamping nut (6) are dierent.

Screw the clamping nut onto the spindle so that the

band of the clamping nut (6) is facing upward.

- Lock the spindle (see chapt

nut (6) clockwise using the 2-hole spanner (5) to secure.

T

- Lock the spindle (see chapt

(6) anticlockwise using the 2-hole spanner (5) to unscr

. USE

8.1 Working close to walls

T

chine and pull the mains plug. The acc

must be s

Only raise the segment (13) when w

walls. Otherwise, the segment must be lower

The open area of the safe

of the wall.

8.2 Setting the speed

Set the optimum speed on the se-

ing on the application. A wheel set

is suitable for mos

8.3 Switching On and O

Always guide the machine with bo

Switch on firs

the workpiece.

The machine must no

additional dust and shavings. When switching the

machine on and o

switching o the machine, only set it down when the mo

has come to a s

Avoid inadvert

o when the plug is remov

socket or if ther

In c

running if it is for

always hold the machine with both hands using the han-

dles provided, st

the work.

Machines with the designation W

T

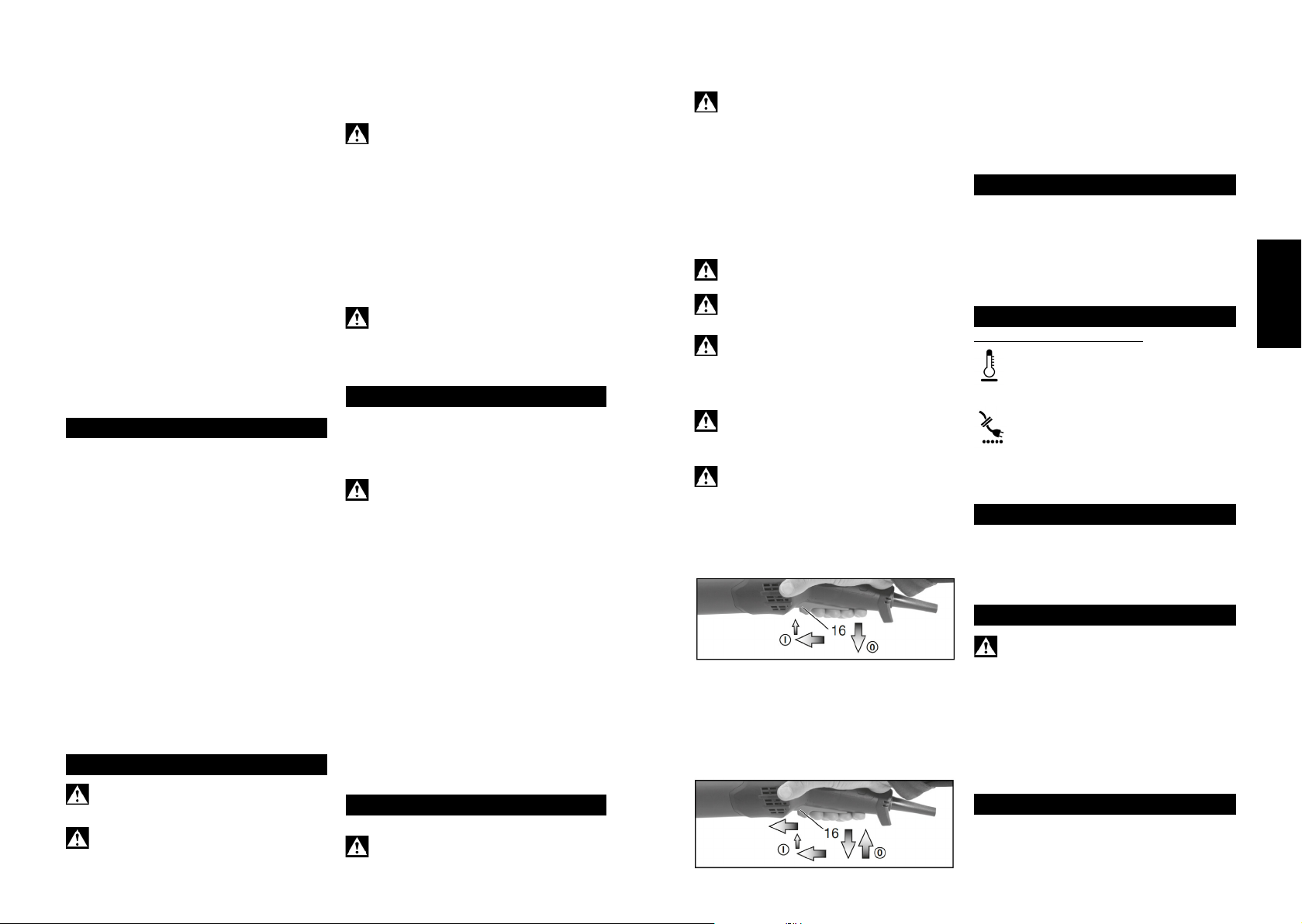

Switching on: Slide the trigger swit

then push the trigger switch (16) upw

Switching o: Rele

Machines with the designation W

Continuous opera

Switching on: Switch the machine on as described abov

Now slide the trigger switch (16) f

in the front position to lock the trigg-

ous opera

Switching o: Push the trigger swit

release.

een korte rus

. CLEANING, MAINTENANCE

Mot The machine must be v

frequently and thoroughly through the ventila

using a suitable v

held firmly in this case.

Replacing the spring-mounted ring brush: R

brushes for optimal dus

set: Order No. 6.28214.

Meetwaarden bep

. TROUBLESHOOTING

Machines with VTC and T

The electr

load speed decreases (noTher

too much load on the machine! Run the machine in

idling until the electronics signal indica

The machine does not s

display (17) (depends on model) flashes. The

rest

inserted with the machine switched on, or if the pow

supply is rest

does not s

. AC

Use only genuine Car

that fulfil the requirement

these opera

acc

the cat

. REP

Repairs t

qualified electricians ONL

must only be replac

from Dara

If you have Cara

please cont

For addresses see www

Y

www

. ENVIRONMENT

The sanding dust gener-

rials: do not dispose of this dus

at a special collec